ISO Certifications for Safety Equipment and Supplies Manufacturing Businesses, Requirements and Benefits

In the safety equipment and supplies manufacturing sector, adhering to globally recognized standards is not a recommendation—it’s a necessity. With increasing regulatory demands and market expectations, ISO certifications ensure that manufacturers meet rigorous safety and operational efficiency benchmarks.

The International Organization for Standardization (ISO) sets globally recognized benchmarks that ensure product safety, environmental sustainability, and operational excellence. For manufacturers of safety equipment and supplies, these certifications signify adherence to high-quality processes and commitment to protecting lives.

ISO standards address critical aspects of the manufacturing process, from product quality and workplace safety to environmental management. Compliance demonstrates reliability and fosters trust among clients, partners, and end-users. In today’s competitive landscape, an ISO-certified company stands as a beacon of quality and dependability.

Send your inquiries and requirements to support@pacificcert.com for prompt assistance with ISO certification processes.

Applicable ISO Standards for Safety Equipment and Supplies Manufacturing

ISO 9001: Quality Management Systems: ISO 9001 establishes a framework for quality management systems (QMS). It ensures consistent product quality, efficient processes, and customer satisfaction. For safety equipment manufacturers, it ensures products meet stringent safety and performance criteria.

ISO 45001: Occupational Health and Safety Management: ISO 45001 focuses on occupational health and safety (OHS). It is pivotal for manufacturing environments where employee safety is paramount. This standard helps organizations mitigate workplace hazards and create safer working conditions.

ISO 14001: Environmental Management Systems: Given the environmental impact of manufacturing activities, ISO 14001 addresses sustainable practices. This standard helps manufacturers minimize environmental footprints through effective resource management and pollution control.

ISO 13485: Medical Devices: For manufacturers of medical safety equipment, ISO 13485 is critical. It outlines the requirements for a QMS tailored to the medical devices industry, ensuring compliance with regulatory standards for medical-grade products.

ISO 50001: Energy Management Systems: Energy-intensive manufacturing processes benefit from ISO 50001, which focuses on optimizing energy usage. Implementing this standard can lead to reduced energy costs and a lower environmental impact.

ISO 22301: Business Continuity Management: Safety equipment manufacturers must ensure uninterrupted operations during emergencies. ISO 22301 helps organizations prepare for, respond to, and recover from disruptive incidents.

ISO 31000: Risk Management: Risk management is vital for manufacturing high-stakes safety equipment. ISO 31000 provides guidelines for identifying, assessing, and managing risks effectively.

Click here to find out more applicable standards to your industry

Pacific Certifications specializes in providing ISO certification services tailored to safety equipment and supplies manufacturing. Our experienced auditors ensure that your processes align with the relevant ISO standards, issuing certifications upon successful compliance. As a trusted certification body, we empower manufacturers to achieve excellence and build credibility in global markets.

Why Choose Pacific Certifications?

- Expertise in safety equipment manufacturing certifications.

- Accredited certification processes.

- Timely and professional audit services.

To discuss your certification needs, contact us at support@pacificcert.com.

Speak to our certification specialists by calling +91-8595603096 for personalized guidance.

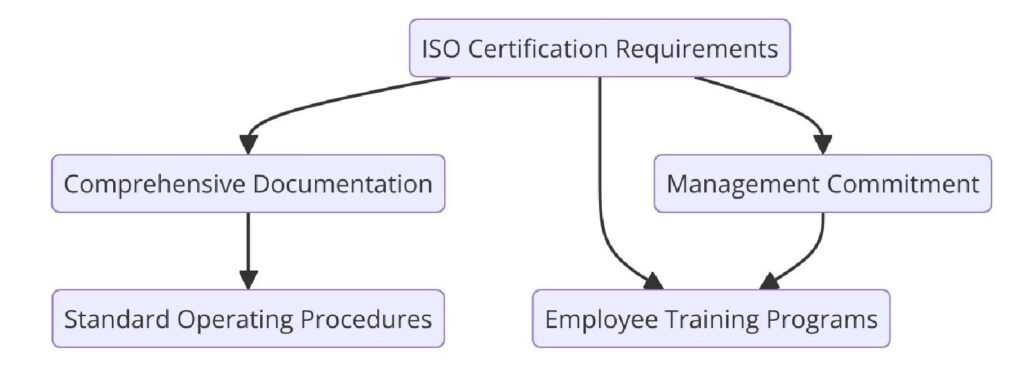

Requirements of ISO Certifications for Safety Equipment and Supplies Manufacturing

Each ISO standard applicable to safety equipment and supplies manufacturing has its unique requirements. Below, we break down the critical requirements for each standard to help you understand what is expected.

ISO 9001: Quality Management Systems

ISO 9001 focuses on establishing and maintaining a robust quality management system (QMS). Key requirements include:

- Documented Processes: Develop a Quality Manual, procedures, and work instructions to ensure consistent product quality.

- Customer Focus: Identify customer needs and strive to exceed expectations through quality products and services.

- Process Approach: Define and manage interconnected processes to improve efficiency and effectiveness.

- Risk-Based Thinking: Identify risks and opportunities to prevent potential issues and capitalize on improvements.

- Continuous Improvement: Establish mechanisms for regular evaluation and enhancement of processes.

- Performance Monitoring: Measure and analyze key performance indicators (KPIs) to ensure alignment with objectives.

ISO 45001: Occupational Health and Safety Management Systems

ISO 45001 ensures a safer work environment by mitigating health and safety risks. Its requirements include:

- Hazard Identification: Conduct thorough risk assessments to identify workplace hazards.

- Control Measures: Implement and maintain controls to reduce or eliminate risks to employee safety.

- Worker Involvement: Engage employees in health and safety decision-making processes.

- Incident Reporting: Develop a mechanism for reporting, investigating, and learning from workplace incidents.

- Emergency Preparedness: Establish and test emergency response plans to handle unforeseen events effectively.

- Compliance Obligations: Ensure adherence to applicable legal and regulatory OHS requirements.

ISO 14001: Environmental Management Systems

ISO 14001 promotes sustainable practices and reduced environmental impact. Its requirements include:

- Environmental Policy: Develop an organization-wide policy addressing environmental goals and commitments.

- Environmental Aspects Identification: Identify activities, products, or services that interact with the environment.

- Legal Compliance: Adhere to environmental laws and regulations relevant to your industry.

- Resource Management: Optimize energy, water, and raw material usage to minimize waste.

- Pollution Prevention: Implement controls to reduce emissions, discharges, and waste generation.

- Performance Evaluation: Regularly monitor environmental performance and identify opportunities for improvement.

ISO 13485: Medical Devices (Safety Equipment in Healthcare)

ISO 13485 focuses on quality management for medical safety equipment manufacturing. Key requirements include:

- Regulatory Compliance: Ensure product design and manufacturing align with applicable medical device regulations.

- Risk Management: Incorporate risk analysis throughout the product lifecycle to mitigate potential failures.

- Product Traceability: Maintain detailed records of raw materials, production batches, and supply chains.

- Validation Processes: Validate all critical manufacturing and testing processes to ensure consistent outcomes.

- Sterilization Standards: Adhere to stringent sterilization protocols for medical-grade safety equipment.

- Post-Market Surveillance: Monitor and respond to customer feedback and product performance in the market.

ISO 50001: Energy Management Systems

ISO 50001 is essential for optimizing energy consumption in manufacturing processes. Its requirements include:

- Energy Policy: Establish a formal policy for energy management, including reduction goals.

- Energy Review: Conduct an energy audit to identify significant energy usage and inefficiencies.

- Baseline Establishment: Define energy performance baselines to measure future improvements.

- Energy Performance Indicators (EnPIs): Develop metrics to track energy performance.

- Operational Control: Implement energy-efficient practices in manufacturing and facility management.

- Continuous Monitoring: Regularly monitor and document energy consumption patterns.

ISO 22301: Business Continuity Management Systems

ISO 22301 helps manufacturers prepare for disruptions. Requirements include:

- Business Impact Analysis (BIA): Identify critical operations and assess potential impacts of disruptions.

- Risk Assessment: Evaluate threats and vulnerabilities that could affect business continuity.

- Recovery Strategies: Develop plans to restore operations quickly after a disruption.

- Testing and Drills: Conduct regular drills to test business continuity plans.

- Communication Plan: Establish a communication framework for internal and external stakeholders during emergencies.

ISO 31000: Risk Management Guidelines

ISO 31000 provides a structured approach to risk management. Requirements include:

- Risk Framework: Define policies and procedures to manage risks systematically.

- Risk Identification: Identify risks that may impact operational, financial, or strategic goals.

- Risk Analysis: Assess the likelihood and impact of identified risks.

- Risk Mitigation: Implement measures to control or eliminate risks effectively.

- Review and Monitoring: Continuously evaluate risk management processes and make improvements.

By understanding and implementing these standard-specific requirements, safety equipment and supplies manufacturers can ensure compliance, enhance their operations, and build a strong foundation for sustainable growth. Contact Pacific Certifications at support@pacificcert.com to start your ISO certification journey.

Get in touch at +91-8595603096 to explore how Pacific Certifications can help your business comply with ISO standards.

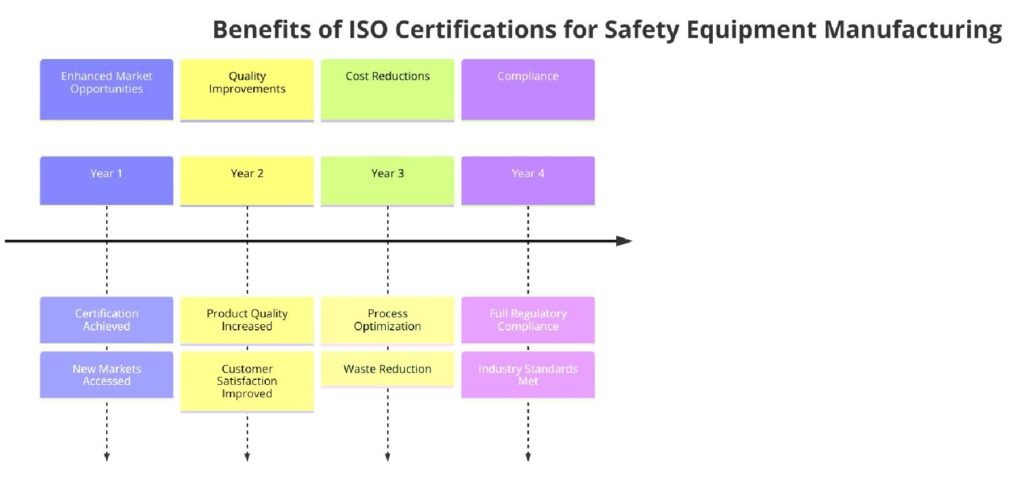

Benefits of ISO Certifications for Safety Equipment and Supplies Manufacturing

Enhanced Product Quality: ISO certifications guarantee that safety equipment meets stringent quality and performance criteria, reducing the risk of malfunctions and enhancing user trust.

Improved Safety: Implementing ISO 45001 minimizes workplace incidents, creating a safer environment for employees and reducing downtime caused by accidents.

Global Market Access: ISO certifications open doors to international markets, as many countries and clients require certified suppliers to ensure compliance with global standards.

Operational Efficiency: ISO standards streamline manufacturing processes, leading to cost savings, reduced waste, and optimized resource utilization.

Brand Credibility: An ISO-certified organization is viewed as a reliable and professional entity. Certifications enhance brand reputation and foster customer loyalty.

Environmental Sustainability: ISO 14001 and ISO 50001 encourage manufacturers to adopt eco-friendly practices, aligning with global sustainability goals and enhancing corporate social responsibility.

The global safety equipment manufacturing sector is projected to grow significantly in this year, driven by increased demand for personal protective equipment (PPE) and industrial safety products. With stricter workplace safety regulations and a growing emphasis on environmental sustainability, ISO-certified manufacturers are better positioned to lead the market. Additionally, advancements in technology are revolutionizing the industry, with innovations like smart safety equipment gaining traction.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Safety Equipment and Supplies manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Safety Equipment and Supplies Manufacturing

ISO certifications ensure compliance with global standards, enhance product quality, and improve workplace safety, making them essential for manufacturers.

Key standards include ISO 9001, ISO 45001, ISO 14001, ISO 13485, and ISO 31000, each addressing specific aspects of quality, safety, and risk management.

ISO 45001 provides a framework for identifying workplace hazards, implementing controls, and promoting a safe working environment.

Yes, ISO certifications are often required by global clients and regulatory bodies, facilitating international market access.

Pacific Certifications offers accredited, professional certification services with a focus on safety equipment and supplies manufacturing.

ISO 14001 and ISO 50001 promote eco-friendly practices, resource optimization, and reduced environmental impact, aligning with sustainability goals.

Read More at: Blogs by Pacific Certifications