The textile and apparel industry is a key player in global trade innovation and employment. It spans the full supply chain—from cotton farming and fiber processing to garment production branding and retail. This sector contributes significantly to GDP in many economies and plays a crucial role in driving exports technology adoption and job creation at every level of the value chain. The sector includes a diverse range of operations—from raw material sourcing and yarn manufacturing to garment production and export logistics.

As global markets emphasize sustainability transparency and responsible sourcing ISO certifications are now critical for businesses across the textile value chain. These certifications help companies align with environmental laws meet buyer expectations and establish themselves as credible trusted suppliers in competitive international markets.

Whether you run a spinning mill garment unit or fashion label adopting ISO standards reflects your dedication to reliable production and responsible practices. These certifications help build stronger process controls, promote better supply chain coordination and support steady day-to-day management across departments. They also assist in meeting customer expectations and staying aligned with industry demands.

To begin your ISO journey or schedule an audit contact us at support@pacificcert.com

Why ISO Certifications matter for Textile & Apparel industry?

The textile industry faces unique challenges including chemical usage environmental emissions labor rights and product consistency. Global buyers increasingly demand transparency, ethical labor practices and quality assurance. ISO certifications offer a clear way to meet these expectations.

Certified organizations are more likely to gain trust from international buyers, avoid compliance issues and access wider markets. Whether in garment export technical textiles or dyeing processes aligning with ISO standards reflects your company’s integrity and readiness.

Today’s business landscape is shaped by growing environmental and social demands. Standards like ISO 14001 and ISO 139 offer tools to manage these expectations while ISO 9001 helps improve product quality and customer satisfaction. These standards serve as valuable frameworks for addressing issues like waste reduction, safe working conditions and consistent product quality.

Applicable ISO standards for the Textile & Apparel industry

ISO 9001:2015 – Quality Management Systems

Ensures consistent production processes from raw material handling to stitching and finishing. It improves documentation, reduces defects and boosts customer satisfaction. It also helps companies better manage customer feedback and corrective actions.

ISO 14001:2015 – Environmental Management Systems

Helps companies manage environmental aspects including water use emissions and waste management—especially useful for dyeing and finishing operations. It supports environmentally conscious decision-making and compliance with local pollution control laws.

ISO 3759:2011 – Preparation, Marking, and Measuring of Fabric Specimens for Textile Testing

This standard provides clear procedures for preparing, marking, and measuring fabric samples before textile testing. By following these guidelines, laboratories and manufacturers can ensure that results are consistent, accurate, and repeatable across different testing environments. It helps eliminate variation caused by inconsistent sample preparation, making it essential for quality control and research purposes.

ISO 139:2005 – Standard Atmospheres for Conditioning and Testing Textiles

ISO 139 sets the environmental conditions—specifically temperature and humidity—that must be maintained when conditioning and testing textile materials. These controlled atmospheres help create uniformity across all test results, regardless of where the testing is conducted. It ensures that the fabric’s performance is not affected by external factors, helping both manufacturers and testing labs get reliable and comparable outcomes.

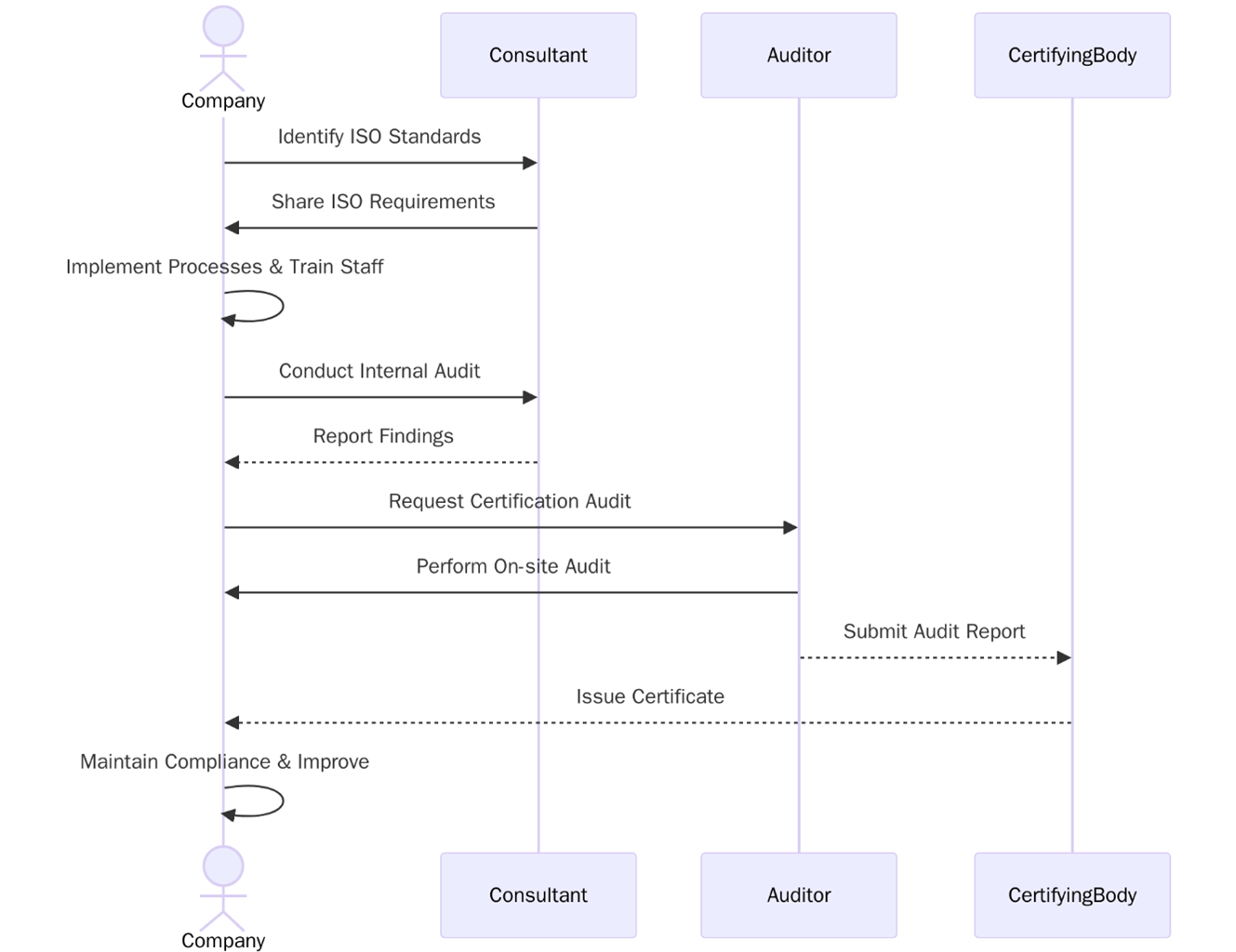

Before initiating the certification process businesses should understand what implementation requires in practical terms. From policy development to internal audits every step contributes to building a strong and traceable management system.

What are the ISO certification requirements for Textile & Apparel industry?

The Textile & Apparel industry involves complex processes, ranging from raw material sourcing and fabric processing to garment manufacturing and distribution. To maintain quality, sustainability, safety, and compliance with international standards, several ISO certifications are applicable, each with specific requirements. Here’s a detailed breakdown:

- Identify the relevant standards based on your processes and customer demands.

- Conduct a gap analysis to assess current practices.

- Create a quality/environmental/social accountability policy.

- Document operational procedures and control points.

- Train employees including floor staff and management.

- Set up monitoring systems for defects emissions and grievances.

- Conduct internal audits and management reviews.

- Submit documentation to an accredited certification body.

- Undergo Stage 1 (document review) and Stage 2 (on-site) audits.

- Address any non-conformities and finalize certification.

- Maintain ongoing compliance through internal and annual surveillance audits.

These steps help textile companies remain compliant and improve how they work. Adopting ISO standards can also support digital transformation inventory control and vendor assessment processes.

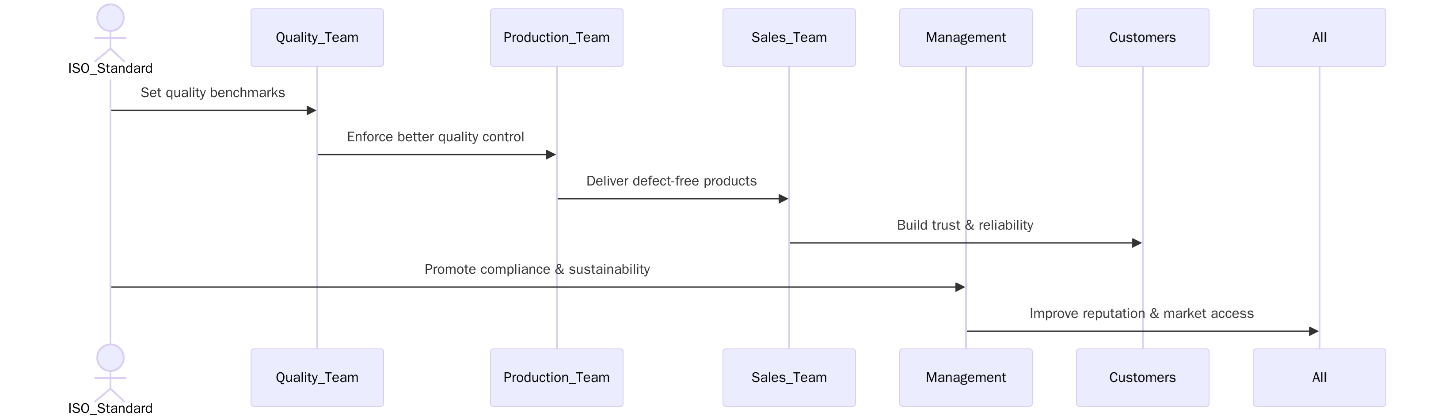

What are the benefits of ISO Certifications for the Textile & Apparel industry?

ISO certifications offer significant advantages to textile and apparel manufacturers and supply chain partners by ensuring compliance to globally recognized standards. Certified companies gain greater market access and reduced operational risks. Below are the key benefits:

- Improved product quality and consistency across production

- Higher customer satisfaction due to defect reduction and reliable delivery

- Eligibility for global tenders and supply chain inclusion

- Better alignment with environmental and labor regulations

- Fewer risks related to waste emissions and labor issues

- Improved documentation and employee training

- Recognition for ethical sourcing and fair labor practices

- Safer and more organized work environments

- Ability to manage multiple standards under one system

- Stronger readiness for brand and regulatory audits

- Greater visibility and transparency in production workflows

- Increased brand reputation among socially responsible consumers

ISO Certification Trends in Textile & Apparel: 2020 vs. 2025

ISO Standard | 2020 Adoption Rate | 2025 Projected Rate | Key Growth Drivers |

ISO 9001 | 68% | 85% | Export requirements buyer compliance |

ISO 14001 | 35% | 70% | Green initiatives pollution control regulations |

SA 8000 | 28% | 60% | Ethical labor sourcing global brand mandates |

As sustainability becomes more important companies are now using ISO systems alongside ERP platforms and audit software for better monitoring and reporting. There’s also a growing trend of linking ISO-certified operations with blockchain-based supply chain verification tools.

How can Pacific Certifications help?

Pacific Certifications, accredited by ABIS offers impartial third-party audits for ISO and SA 8000 certifications tailored to textile operations. Our auditors understand the details of garment manufacturing, spinning dyeing and compliance requirements.

We provide:

- ISO and SA 8000 certification audits for textile units

- Combined audits to reduce disruptions

- Review of documents and policies before the audit

- Flexible scheduling to match production timelines

- Annual checks and renewal audits

We do not provide consultancy services. Our focus is on impartial value-based audits in line with international accreditation standards. We aim to support your organization in building reliable systems that align with international market expectations.

ISO 9001, ISO 14001 & other Training and Courses

Various training courses are available to help organizations comply with ISO and SA 8000 standards, including:

- Internal Auditor Training – Preparing your QA compliance and HR teams to conduct internal audits and maintain compliance.

- Lead Auditor Training – Equips professionals to conduct external third-party or brand-required audits.

- Awareness and Implementation Workshops – Ideal for operational heads, floor supervisors and compliance officers.

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 9001 ISO 14001 training our team is equipped to help you. Contact us at support@pacificcert.com

FAQ: ISO Certifications for Textile & Apparel industry

Which certification should a garment manufacturer prioritize?

ISO 9001 is ideal for quality assurance. SA 8000 and ISO 14001 are key for social and environmental compliance.

How long is the certification valid?

Typically ISO certifications are valid for 3 years with annual surveillance audits.

Can MSMEs and local units also get certified?

Yes. ISO and SA 8000 standards are scalable and suitable for MSMEs with appropriate preparation.

What is the difference between ISO 9001 and SA 8000?

ISO 9001 covers process and quality control while SA 8000 addresses labor conditions and social responsibility.

Does Pacific Certifications assist with implementation?

No. We provide independent certification audits not consultancy.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs