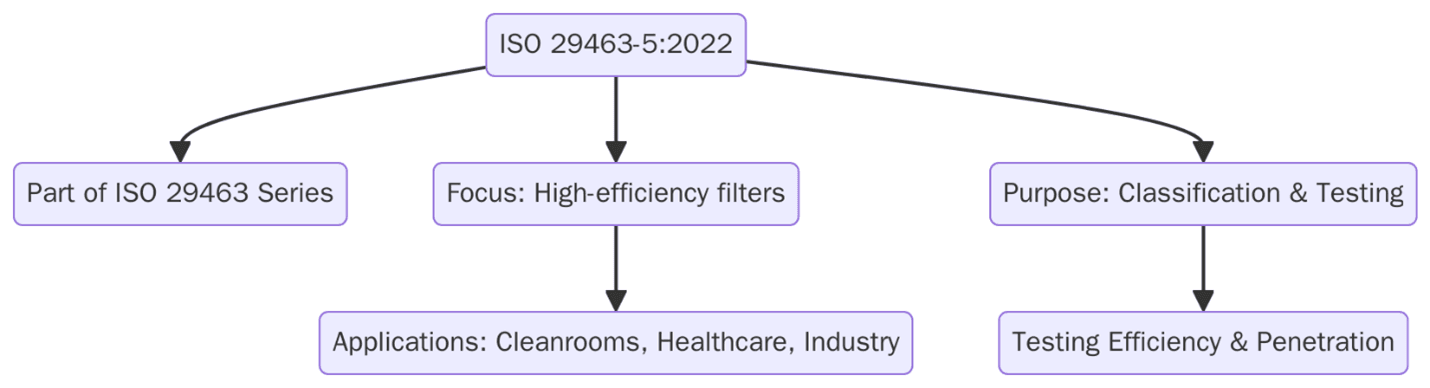

What is ISO 29463-5:2022?

ISO 29463-5:2022 is an international standard that specifies the test methods and classification process for high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters used to remove particles from air. These filters are critical in environments where air cleanliness and contamination control are key, such as cleanrooms or semiconductor manufacturing and even healthcare facilities.

This part of the ISO 29463 series outlines the procedure for determining the filtration performance of these filters. It ensures that the filters are tested under consistent conditions and can be reliably classified according to their efficiency and penetration performance.

To start your certification process or schedule an audit, contact us at support@pacificcert.com

Purpose

The purpose of ISO 29463-5 is to provide a consistent and transparent method for testing and classifying high-efficiency air filters based on particle penetration and efficiency levels. This allows buyers, manufacturers, and users to understand the performance of each filter type, especially in high-stakes environments like medical cleanrooms and electronics production areas.

The standard helps filter manufacturers meet buyer expectations for clean air delivery, assists end users in making informed choices, and supports regulatory inspections where air quality controls are mandated.

Scope and Applicability

ISO 29463-5 applies to high-efficiency filters designed to capture airborne particles from the airstream in controlled environments. The scope includes both HEPA and ULPA filters which are used in settings such as cleanrooms, pharmaceutical labs, hospital operating theatres, electronics production, and food packaging facilities.

It does not apply to lower-grade filters such as coarse filters or general-purpose ventilation filters. The standard applies to flat sheet media as well as assembled filter units. Both manufacturers of filter media and final filter systems will find this standard applicable for product testing and classification.

Key Definitions

- Penetration: The percentage of test aerosol particles that pass through the filter.

- Efficiency: The percentage of aerosol particles captured by the filter, calculated as 100 minus penetration.

- HEPA: High-Efficiency Particulate Air filter typically with efficiency above 99.95%.

- ULPA: Ultra-Low Penetration Air filter with efficiency above 99.9995%.

- MPPS: Most Penetrating Particle Size, the particle size at which the filter performs worst.

Clause-wise Structure of ISO 29463-5:2022

Clause | Title | Description |

1 | Scope | Defines the use of the standard for high-efficiency air filters. |

2 | Normative References | Lists other relevant standards including ISO 29463-1 to ISO 29463-4. |

3 | Terms and Definitions | Explains critical terminology such as MPPS, penetration, and filter classes. |

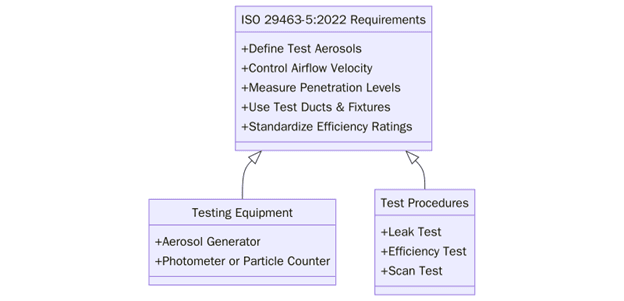

4 | Test Apparatus | Details equipment specifications for aerosol generation, detection, and flow control. |

5 | Testing Procedure | Describes how to prepare, conduct, and measure particle penetration tests. |

6 | Calculation of Efficiency and Penetration | Outlines formulas and data analysis methods for evaluating filter performance. |

7 | Classification | Specifies classification ranges for different filter grades based on performance at MPPS. |

8 | Documentation and Reporting | Defines how results must be documented and what data should be included in reports. |

What are the ISO 29463 requirements?

The standard sets out detailed expectations for how filters should be tested and classified. These requirements ensure each unit is properly evaluated before being released for use in critical air-cleaning applications. Below are the key ISO 29463 requirements:

- Filters must be tested at their MPPS, not at average particle sizes.

- Aerosols used for testing should be neutralized and within size tolerance limits.

- Filter efficiency must be calculated as 100 minus penetration.

- Filters must be classified based on penetration at MPPS as per ISO 29463-1 classes.

- Pressure drop across the filter should be measured during the test.

- Testing equipment should have calibrated aerosol counters, flow meters, and pressure sensors.

- The testing area must be free from background aerosol contamination.

- Results must be clearly documented with test parameters, equipment data, and performance outcome.

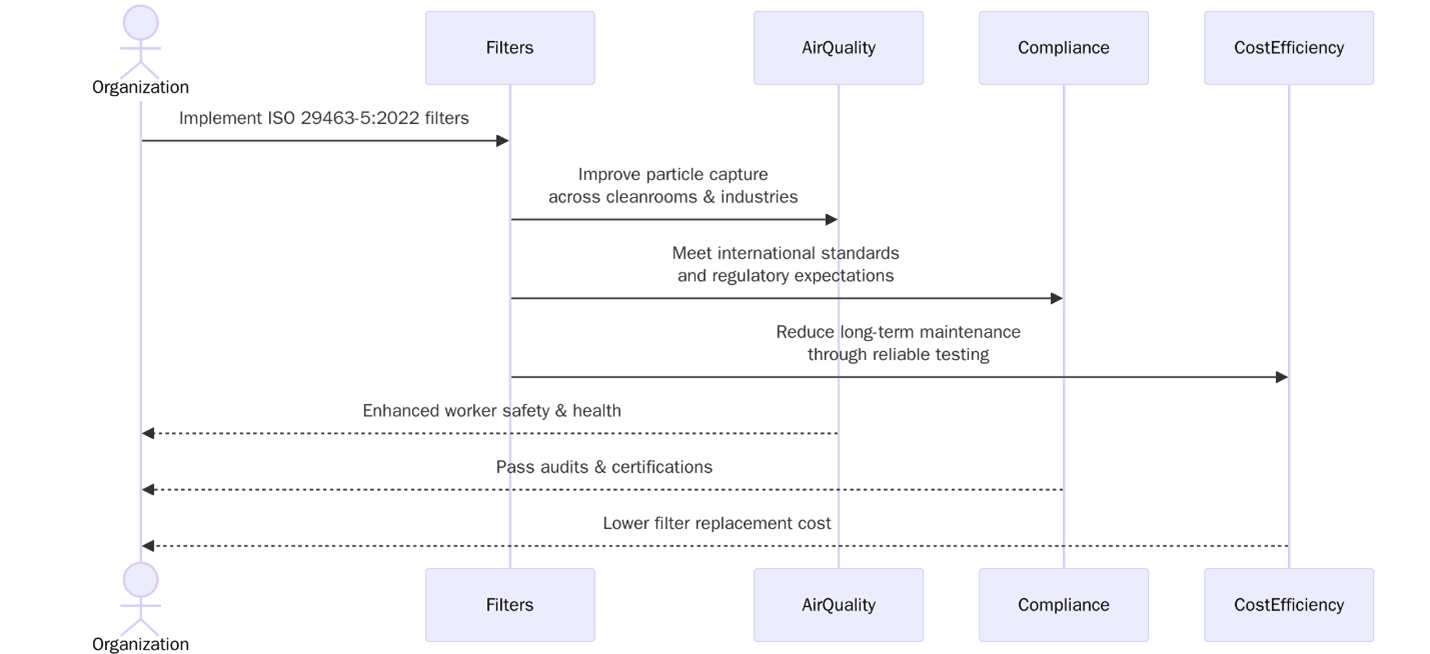

What are the ISO 29463 benefits?

Following ISO 29463-5 brings clarity and consistency to the evaluation of high-efficiency filters. These filters are often used in environments where even minor airborne contamination can lead to equipment damage, medical complications, or product failure. Below are the key ISO 29463 benefits:

- Improves product confidence by confirming actual performance under strict test conditions

- Supports global trade by using a unified classification system for HEPA and ULPA filters

- Reduces guesswork during procurement and engineering design for cleanroom setups

- Helps manufacturers verify that filter batches meet uniform expectations

- Simplifies internal and third-party audits by offering a consistent test reference

- Aligns with international expectations in pharma, semiconductor, and healthcare industries

- Enables lifecycle tracking through standardized labeling and performance reports

As industries like microelectronics, biotechnology, and advanced diagnostics grow, so does the demand for fine-particle filtration. Since 2022, global interest in ISO 29463 filters has increased due to stricter cleanroom controls and new GMP requirements across Asia, the U.S., and Europe. Manufacturers of filters are investing in newer testing chambers and adopting ISO 29463-5 to appeal to high-spec clients. In parallel, governments are referencing ISO 29463 classification in tender specifications for hospital-grade HVAC systems and pharmaceutical packaging lines.

What is the Certification Process for ISO 29463?

The ISO 29463certification process begins by identifying the product to be tested and setting up the correct MPPS aerosol-based testing framework. Pacific Certifications follows a structured certification model:

- Identify filter model and intended classification range (e.g. H13, U17).

- Prepare samples for testing at ISO 29463-accredited labs.

- Perform MPPS aerosol testing and penetration measurement.

- Submit full technical documentation including design specs, material data, and test results.

- Stage 1 audit: Review of technical files and sampling procedures.

- Stage 2 audit: On-site inspection of production and QA methods.

- Final evaluation and issuance of certification, along with usage labeling guidelines.

ISO 29463-5 Certification Timeline

The certification process typically takes between six and eight weeks. If test results from ISO 29463-3 or ISO 29463-4 are already available, this may reduce the timeline. For new designs or untested filter media, additional lab time may extend certification to around ten weeks.

What is the ISO 29463-5 Certification cost?

iso 29463 Certification costs depend on the number of filter types, whether batch testing or single sample testing is required, and whether prior reports exist for the filter media. Products using pre-qualified filter media may reduce overall costs. Bundled audits with ISO 29463-1 to 29463-4 can also bring savings for large filter manufacturers.

How can Pacific Certifications Help?

Pacific Certifications supports manufacturers, contractors, and filter integrators with independent third-party testing and certification for ISO 29463-5. We guide clients through test setup, lab selection, and conformity audits.

- We validate test setups for MPPS-based performance measurement

- We review and verify classification decisions based on test results

- We check data sheets, labels, and packaging for accurate filter class representation

- We assist in preparing for internal or external audits tied to cleanroom standards

- We provide combined audits for ISO 14644, ISO 29463-1 to 5, and related clean air standards

Training and Courses

Lead Auditor Training: Designed for professionals assessing filter performance and classification procedures within ISO 29463 standards.

Lead Implementer Training: Helps engineers and quality heads embed ISO 29463 principles into their product development and manufacturing pipelines.

Internal Auditor Training: Supports QA and maintenance teams in maintaining filter certification through process checks and batch testing.

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 29463-5 training, our team is equipped to help you. Contact us at support@pacificcert.com

FAQs

What is the difference between ISO 29463 and EN 1822?

ISO 29463 is derived from EN 1822 but extends it with global compatibility. Many companies now adopt ISO 29463 for international trade and documentation.

Do all cleanrooms require ISO 29463 filters?

Not all, but cleanrooms classified as ISO Class 5 or cleaner typically rely on HEPA or ULPA filters tested to this standard.

Can I certify only the media and not the assembled filter?

Yes, ISO 29463-2 to 4 allows media-level testing. However, ISO 29463-5 is for full filters.

Is ISO 29463-5 recognized globally?

Yes, it’s referenced in procurement, GMP standards, and hospital HVAC specifications in over 40 countries.

Do I need a lab to be ISO-certified to test under 29463-5?

Yes, testing must be conducted at facilities that meet the instrumentation and aerosol control requirements listed in ISO 29463-5.

What does ISO 29463-5:2022 actually test?

It specifies the factory test method for complete HEPA/ULPA filter elements, determining their efficiency at the most penetrating particle size (MPPS). It also gives guidance for filters with MPPS < 0.1 μm and for charged synthetic-fibre media (annexes B and C).

What is MPPS and why does the standard use it?

MPPS (Most Penetrating Particle Size) is the particle size a filter finds hardest to stop; measuring at MPPS gives a conservative (worst-case) efficiency. For typical HEPA elements, MPPS is often around 0.1–0.2 μm

Which aerosols are acceptable for ISO 29463 testing?

The standard family allows commonly used challenge aerosols such as DEHS/PAO or PSL; selections and details follow the harmonized EN 1822/ISO 29463 approach used in HEPA/ULPA factory tests.

How are filters classified under ISO 29463?

Filters are grouped by overall and local efficiency at MPPS into EPA, HEPA and ULPA classes (e.g., ISO 35 H/40 H/45 H for HEPA and ISO 50 U–75 U for ULPA). These map broadly to EN 1822 classes H13–U17.

How does Part 5 relate to leakage “scan” testing?

Part 5 covers the overall (integral) efficiency test of a finished element. Leakage (local) scan testing is defined separately in ISO 29463-4; many labs run both to report integral performance and local leak tightness.

Ready to get ISO 29463 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs