ISO 10012:2003 Certification Process, Documents Required, Fees, Eligibility, Duration

ISO 10012:2003, Measurement Management Systems – Requirements for Measurement Processes and Measuring Equipment, is a globally recognized standard providing essential guidelines for accurate, reliable, and consistent measurement outcomes. Obtaining ISO 10012 certification enables organizations to significantly enhance their measurement processes, ensuring compliance with quality standards and customer expectations.

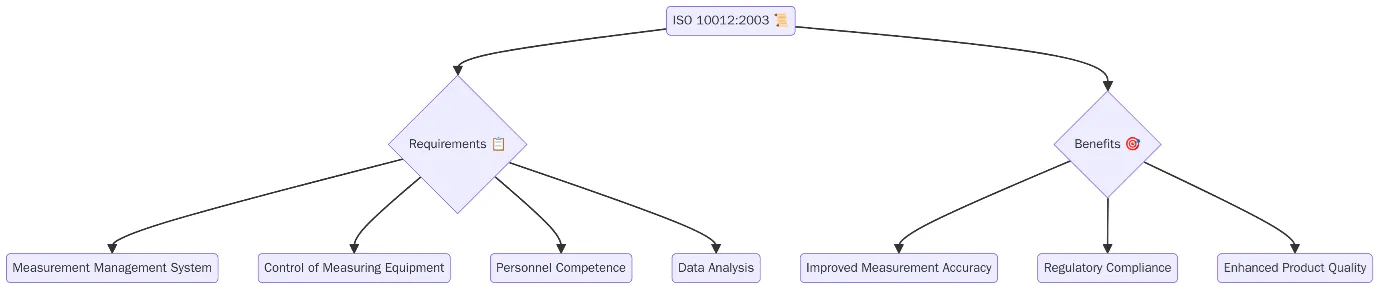

Understanding ISO 10012:2003

ISO 10012 offers detailed requirements for effectively managing measurement processes and equipment. The standard aims to ensure that measuring equipment and measurement processes are appropriate, adequately calibrated, and capable of delivering precise results. Organizations that comply with ISO 10012 benefit from improved measurement accuracy, reduced errors, and higher quality products or services.

If you are looking for ISO 10012 certification for your organization, please get in touch with us at support@pacificcert.com.

Certification Process and Procedure

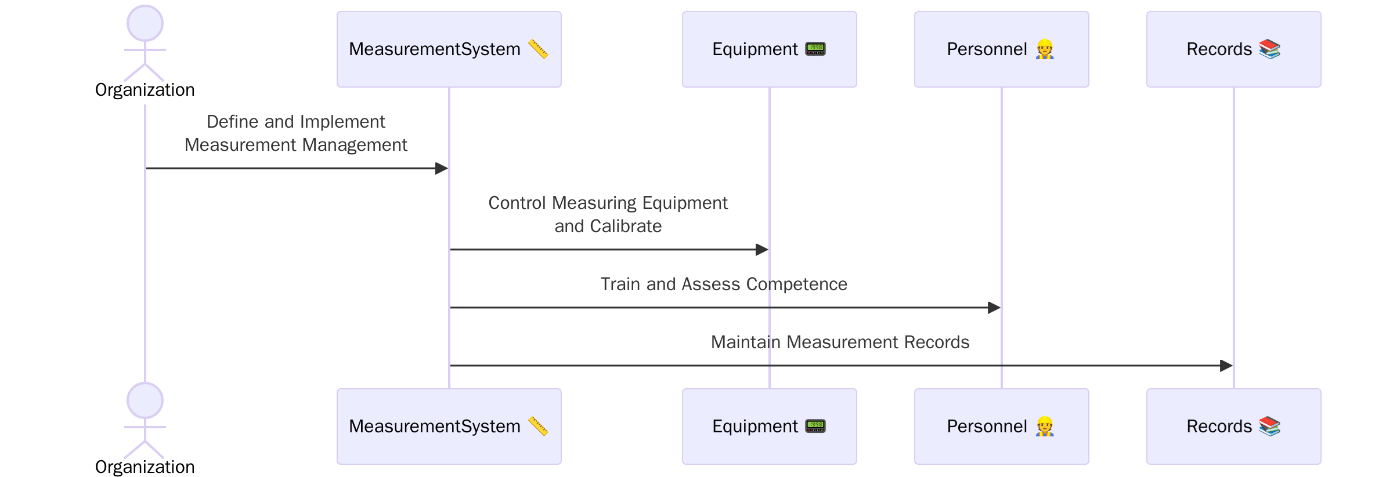

Step-by-Step Certification Process:

- Initial Assessment & Gap Analysis:

- Comprehensive review of existing measurement management practices.

- Detailed identification of gaps and opportunities for improvement.

- Planning & Documentation:

- Drafting or revising measurement management manuals.

- Creating detailed operational procedures, calibration processes, and record-keeping practices.

- Implementation Phase:

- Integrating revised measurement management processes across operations.

- Conducting extensive training sessions to ensure staff competency.

- Internal Audit & Corrective Actions:

- Performing systematic internal audits to verify adherence to ISO 10012 requirements.

- Implementing corrective and preventive actions based on audit findings.

- Management Review:

- Organizing regular management reviews to ensure the effectiveness and adequacy of measurement systems.

- Documenting review outcomes and actions for continuous improvement.

- External Certification Audit:

- Engaging Pacific Certifications for external audits, including documentation review (Stage 1) and comprehensive on-site assessments (Stage 2).

- Certification Award:

- Successfully meeting the standard’s criteria and achieving certification.

Documents Required for Certification

- Measurement Management System Manual

- Calibration and measurement procedures documentation

- Calibration schedules and maintenance logs

- Records of calibration results

- Internal audit reports and corrective action logs

- Management review records and minutes

- Personnel training documentation

- Records of measurement uncertainty evaluations

- Document control and management system records

Eligibility Criteria- ISO 10012

Organizations across diverse sectors utilizing measurement equipment in their production, quality control, and testing processes are eligible for ISO 10012 certification. Key sectors include:

- Manufacturing industries (automotive, electronics, etc.)

- Pharmaceutical and healthcare industries

- Testing and calibration laboratories

- Aerospace and defense

- Research and development organizations

- Regulatory compliance-focused sectors

Certification Fees and Cost Estimation

Certification fees vary based on:

- Organizational size and complexity

- Number and nature of measurement processes

- Geographic location

For precise quotations tailored to your organization’s specific needs, contact Pacific Certifications at support@pacificcert.com.

Duration of Certification Process

Typically, the timeline for ISO 10012 certification includes:

- Preparation and documentation: 2-4 months

- Implementation and training: 1-3 months

- Internal audit and corrective actions: 1 month

- External certification audit: 1 month

Total duration usually spans 5-9 months from initial planning to certification issuance.

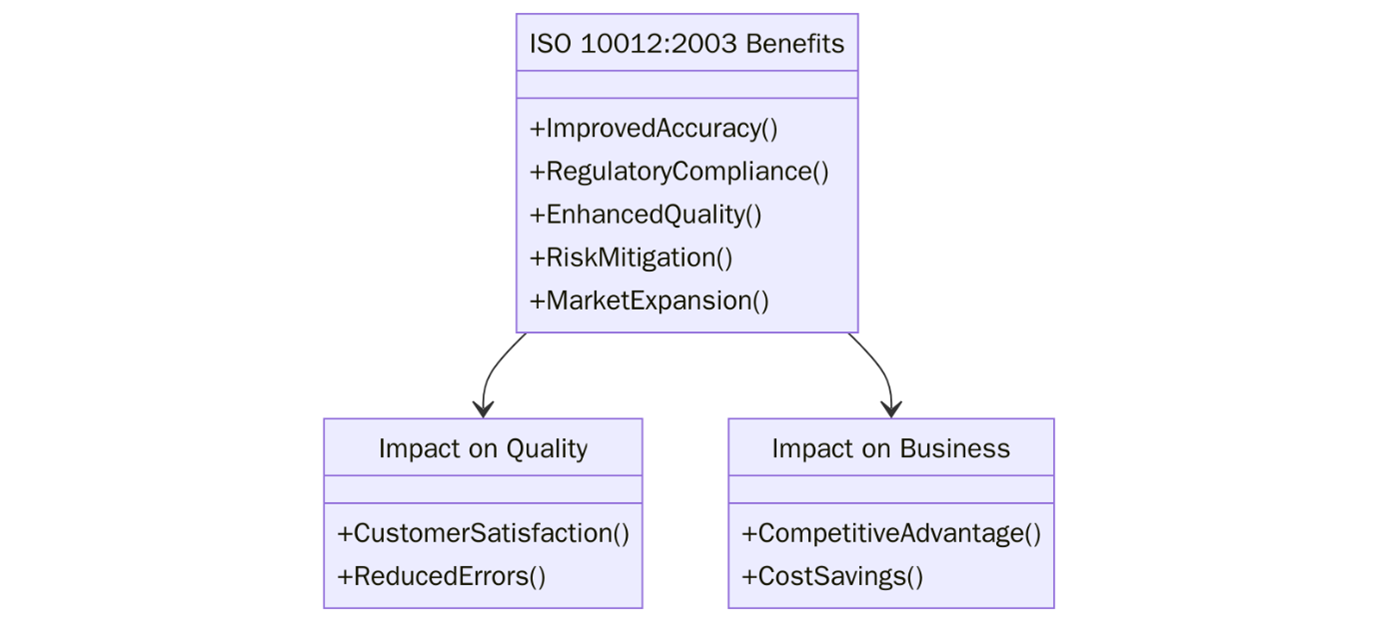

Benefits of ISO 10012 Certification

- Ensures measurement accuracy and consistency

- Improves compliance with quality standards

- Enhances customer confidence and satisfaction

- Reduces measurement-related errors and associated costs

- Facilitates international recognition and market competitiveness

- Strengthens internal operational efficiency and process reliability

The global trend towards rigorous quality standards and compliance drives the increasing demand for ISO 10012 certification. Industries such as healthcare, automotive, aerospace, and pharmaceuticals, where measurement precision directly affects product safety and quality, see significant growth in adopting ISO 10012 standards. Organizations recognize certification as essential for maintaining competitive advantage and regulatory compliance in stringent international markets.

How Pacific Certifications can help?

Pacific Certifications provides extensive support and expertise throughout your ISO 10012 certification process:

- Expert Auditors: Our auditors possess deep industry knowledge and experience, ensuring precise, valuable assessments.

- Credibility: Certification from Pacific Certifications, accredited by ABIS, boosts your credibility and marketability internationally.

- Our team provides detailed support during every step, from documentation preparation to achieving and maintaining certification.

- Regular surveillance audits and ongoing consultancy help maintain compliance and encourage continual improvement.

For further assistance or to initiate your certification process, please contact us at support@pacificcert.com.

Frequently Asked Questions (FAQs)

What is the validity period of ISO 10012 certification?

ISO 10012 certification is valid for three years, subject to regular annual surveillance audits to ensure ongoing compliance.

Yes, ISO 10012 aligns seamlessly with other management standards, such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety).

Comprehensive training is mandatory to ensure personnel are competent and capable of effectively managing measurement processes.

Equipment calibration intervals vary depending on usage, equipment type, and manufacturer recommendations but typically range from bi-annual to annual intervals.

ISO 10012 certification significantly enhances compliance with measurement accuracy requirements; however, complete regulatory compliance may necessitate additional industry-specific certifications or adherence to specialized regulations.

Contact Us

If you need support with ISO 10012:2003 certification, contact us at support@pacificcert.com.

Read More at: Blogs by Pacific Certifications