ISO Certifications for Communication Equipment Manufacturing Businesses, Requirements and Benefits

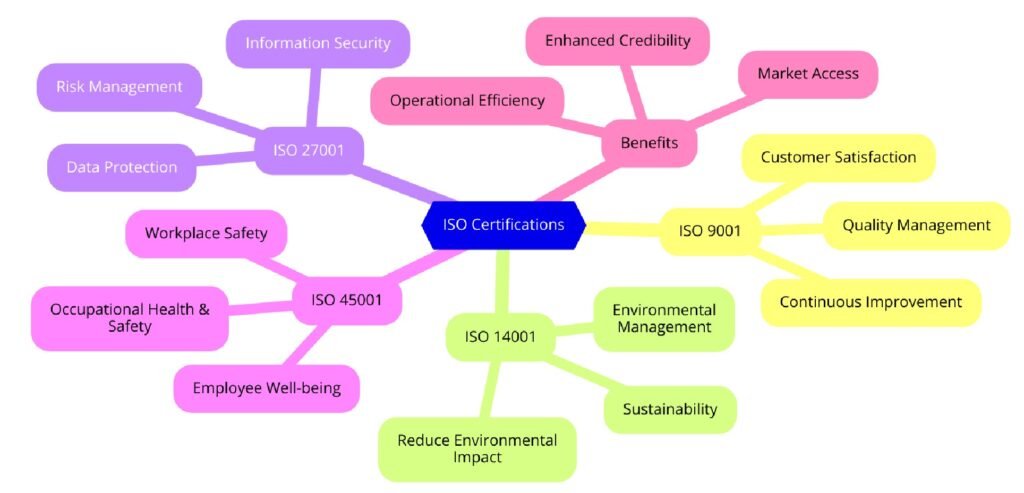

In the competitive world of communication equipment manufacturing, maintaining high standards for quality, safety, and environmental responsibility is vital. This is where ISO certifications play a crucial role, providing a structured approach to achieving excellence. For manufacturers in this industry, certifications such as ISO 9001, ISO 14001, ISO 45001, and ISO 27001 ensure consistent product quality, secure data management and eco-friendly practices.

Introduction to ISO Standards for Communication Equipment Manufacturing

ISO standards are globally recognized frameworks that outline best practices for quality, safety, and sustainability. For communication equipment manufacturers, these standards establish guidelines to ensure devices meet industry expectations and regulatory requirements. Standards like ISO 9001 for quality management and ISO 14001 for environmental management play significant roles in establishing trust and reliability in the products provided by certified companies.

If ISO certification for Communication Equipment Manufacturing is on your agenda, reach out to us at support@pacificcert.com or call us at +91-8595603096. We’re here to help!

Applicable ISO Standards for Communication Equipment Manufacturing

Communication equipment manufacturing encompasses a broad range of standards that address different aspects of production, quality, and management. Below are some key ISO certifications relevant to this sector:

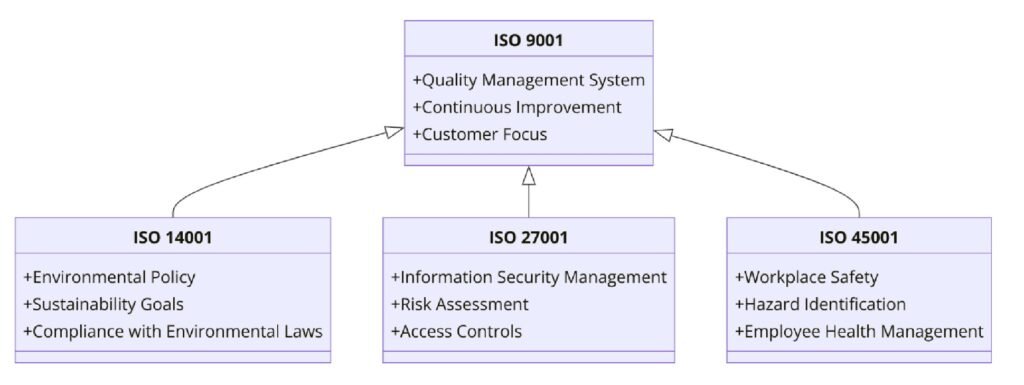

- ISO 9001: Quality Management System (QMS) ISO 9001 focuses on maintaining a high level of product quality and operational consistency. This standard provides a framework for ensuring customer satisfaction through continuous improvement and effective management practices. For communication equipment manufacturers, ISO 9001 certification demonstrates a commitment to quality and reliability.

- ISO 14001: Environmental Management System (EMS) As environmental impact becomes a pressing concern, ISO 14001 certification helps manufacturers minimize their ecological footprint. This standard requires companies to assess and mitigate the environmental impact of their operations, ensuring sustainable production practices that align with regulatory requirements and corporate responsibility.

- ISO 45001: Occupational Health and Safety Management System (OHSMS) ISO 45001 addresses workplace safety, helping organizations provide safe working conditions and prevent work-related injuries and illnesses. For manufacturing environments that involve machinery and potentially hazardous processes, this certification is crucial for ensuring employee safety and well-being.

- ISO/IEC 27001: Information Security Management System (ISMS) With the growing importance of data security in communication technology, ISO/IEC 27001 certification helps manufacturers safeguard sensitive information. This standard sets requirements for information security management, covering areas such as data confidentiality, integrity, and availability.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in auditing and certifying organizations in accordance with ISO standards. For communication equipment manufacturers seeking compliance, our certification services provide the verification needed to demonstrate commitment to global standards. Our team conducts rigorous audits to assess compliance, ensuring that your organization’s practices align with ISO requirements.

Pacific Certifications has a track record of helping communication equipment manufacturers across the globe achieve ISO certification, paving the way for improved market access and increased operational efficiency. By partnering with us, your organization can benefit from our extensive expertise and dedication to delivering accurate, unbiased certification results. Email us at support@pacificcert.com to get started!

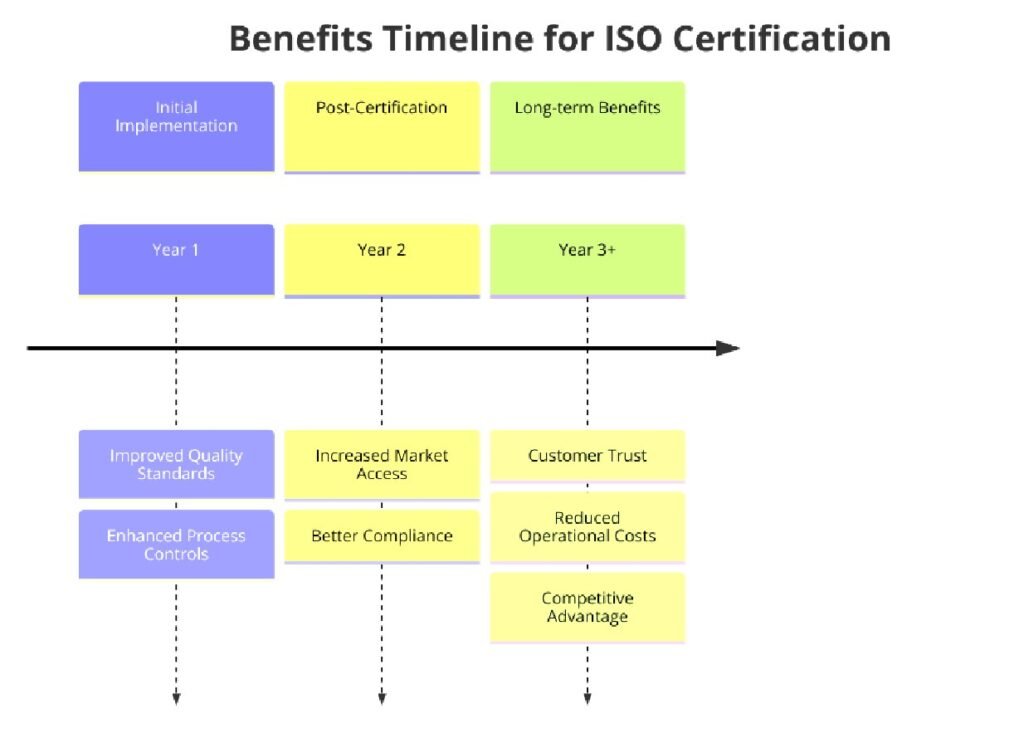

Cost of ISO Certification

The cost of ISO certification varies based on factors such as company size, the complexity of operations, and the number of standards pursued. Initial certification investments are typically outweighed by long-term benefits like efficiency gains and improved marketability.

Certification Process Overview

The certification process for communication equipment manufacturers generally follows these steps:

- Initial Assessment and Gap Analysis: Evaluating current practices to identify areas of non-compliance.

- Documentation and System Review: Ensuring policies, procedures, and records align with ISO standards.

- On-Site Audit: A comprehensive inspection by Pacific Certifications auditors.

- Certification Issuance: Upon successful audit completion, we provide the official certification.

- Surveillance Audits: Regular follow-up audits to ensure continuous compliance.

Requirements of ISO Certifications for Communication Equipment Manufacturing

Meeting the requirements of relevant ISO standards involves detailed planning, implementation, and continuous improvement. Here’s an overview of key requirements based on specific ISO standards:

ISO 9001: Quality Management Requirements:

ISO 9001 requires companies to develop a Quality Management System (QMS) that focuses on customer satisfaction, efficient processes, and continual improvement. Manufacturers need to:

- Identify key processes impacting quality and ensure they’re monitored and controlled.

- Establish clear quality policies and objectives.

- Implement consistent documentation practices and maintain records.

- Engage in regular internal audits to verify compliance and identify areas for improvement.

ISO 14001: Environmental Management Requirements:

To achieve ISO 14001 certification, companies must create an Environmental Management System (EMS) that helps reduce environmental impact. Key requirements include:

- Conducting an environmental impact assessment for manufacturing activities.

- Setting clear objectives to reduce waste, improve energy efficiency, and minimize emissions.

- Establishing procedures for monitoring and controlling waste management and resource use.

- Engaging employees in sustainable practices and providing environmental training.

ISO 45001: Occupational Health & Safety Requirements:

ISO 45001 certification focuses on creating a safe work environment. Requirements for this certification include:

- Conducting risk assessments to identify and control workplace hazards.

- Establishing health and safety policies and emergency procedures.

- Regular training and engagement for employees on safe practices.

- Ongoing monitoring and reporting on health and safety performance, with continual improvement measures.

ISO 27001: Information Security Management Requirements:

This certification requires companies to set up an Information Security Management System (ISMS) to protect sensitive information. Key requirements are:

- Conducting a risk assessment to identify potential information security threats.

- Implementing information security policies covering data access, handling, and storage.

- Regularly updating the ISMS to reflect changes in the technology and threat landscape.

- Training employees on data security and awareness practices.

For ISO certification expertise in Communication Equipment Manufacturing, contact our team at support@pacificcert.com or call +91-8595603096 today.

Benefits of ISO Certifications for Communication Equipment Manufacturing

ISO certifications provide numerous advantages that strengthen business operations and enhance brand reputation:

- Product Quality: ISO 9001 ensures consistent quality and reliability, essential in a competitive industry.

- Environmental Responsibility: ISO 14001 aligns the company’s goals with sustainability, helping to reduce its ecological footprint.

- Employee Safety: ISO 45001 promotes a safe and healthy workplace, improving employee morale and reducing accident-related downtime.

- Data Security: ISO 27001 safeguards sensitive data, making the company a trusted partner in sectors where data privacy is essential.

Market Trends

In 2024, the communication equipment manufacturing sector continues to witness exponential growth due to the increasing demand for advanced networking and telecommunication solutions. Trends such as 5G expansion, IoT integration, and enhanced data security measures drive the adoption of ISO certifications as manufacturers strive to meet high standards.

Furthermore, environmental sustainability remains a key focus, pushing more manufacturers to adopt ISO 14001 to comply with green initiatives and eco-friendly practices. The emphasis on global compliance and certification is a strategic approach for companies to stay competitive in this dynamic market.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Communication Equipment Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Communication Equipment Manufacturing

What is the purpose of ISO certifications for communication equipment manufacturing?

ISO certifications provide a framework that ensures high-quality, safe, and environmentally responsible manufacturing practices. They help manufacturers maintain global standards, improve efficiency, and ensure product reliability.

Which ISO standards are most relevant for communication equipment manufacturers?

Some of the most applicable standards include ISO 9001 for quality management, ISO 14001 for environmental management, ISO 45001 for occupational health and safety, ISO/IEC 27001 for information security, and ISO/IEC 17025 for testing and calibration.

How does ISO 45001 benefit communication equipment manufacturers?

ISO 45001 ensures that manufacturers provide safe working conditions, reducing risks of accidents and illnesses. A safe workplace promotes employee well-being and productivity, contributing to overall operational efficiency.

What is the role of ISO/IEC 17025 in communication equipment manufacturing?

ISO/IEC 17025 ensures that testing and calibration processes are accurate and reliable, which is essential for the performance of communication equipment. This certification is especially valuable for companies that perform in-house testing.

How can Pacific Certifications assist with ISO certification?

Pacific Certifications offers comprehensive auditing and certification services to help communication equipment manufacturers meet ISO standards. We assess compliance, ensuring your practices align with global benchmarks.

Why is ISO 22301 important for communication equipment manufacturers?

ISO 22301 certification helps manufacturers develop a business continuity plan to manage disruptions effectively, ensuring uninterrupted service delivery in an industry where continuous operation is crucial.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs