What is ISO 12100?

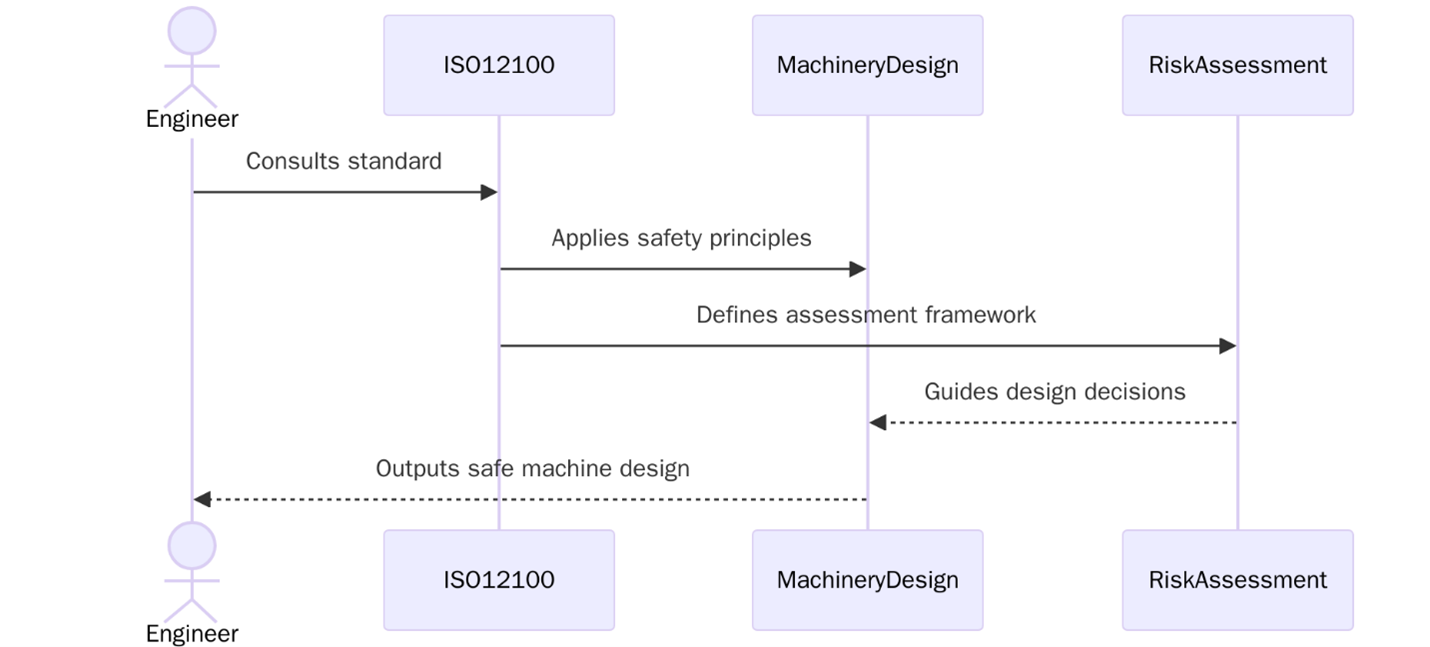

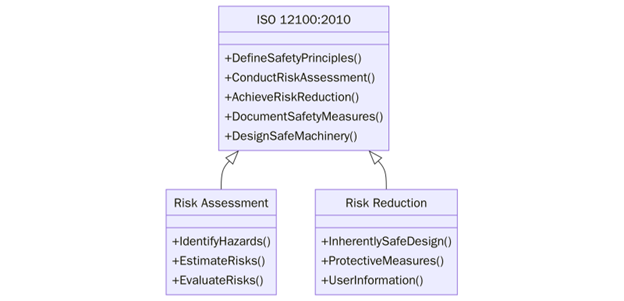

ISO 12100:2010 is an international standard that defines general design principles to reduce risks in machinery used across various industries. It applies to manufacturers who design, assemble or modify machines intended for industrial use. The standard helps incorporate safety features during the design stage by identifying hazards, assessing risks and applying controls.

In sectors such as automotive, oil and gas, packaging, metalworking and construction, machines are essential to daily work. These include everything from conveyor belts and robotic systems to injection molding machines and hydraulic presses. ISO 12100 supports engineers and safety teams in building machines that reduce risks by design rather than relying on protective guards or warning signs after production.

To begin your ISO journey or schedule an audit, contact support@pacificcert.com

Purpose of ISO 12100

The purpose of ISO 12100 is to help designers reduce risk at the source. Instead of responding to hazards later in a machine’s lifecycle, the standard promotes a structured approach where safety is addressed during design. It guides how to identify potential harm, evaluate the risk, and choose measures to reduce or eliminate it. This process allows for safer machines and fewer workplace injuries, leading to better user trust and reduced downtime.

Scope and Applicability

ISO 12100 applies to the design of all machinery intended for use by operators in industrial or commercial settings. This includes stationary equipment like lathes and mills, mobile machines such as forklifts or excavators, and semi-automated systems used in packaging or processing plants.

The standard can be used across multiple industries, including:

- Manufacturing and fabrication

- Oil and gas equipment manufacturing

- Agriculture and forestry machinery

- Pharmaceutical production

- Food and beverage processing

Whether the machine is designed in-house or outsourced, ISO 12100 provides a framework to ensure all safety aspects are considered throughout the design process.

Key Definitions

Hazard: A potential source of harm or adverse health effects.

Risk assessment: A process to identify hazards, evaluate risks, and determine necessary actions.

Inherently safe design measures: Techniques applied in the design stage to eliminate risks rather than controlling them later.

Protective measures: Guards, shields, or control systems that limit exposure to hazards.

Residual risk: Risk remaining after all safety measures are applied.

Clause-wise Structure of ISO 12100:2010

Clause Number | Title | Description |

1 | Scope | Defines where the standard applies and its intended users |

2 | Normative References | Cites documents necessary to apply the standard |

3 | Terms and Definitions | Explains technical language used throughout the standard |

4 | General Principles | Introduces fundamental concepts for safe design |

5 | Strategy for Risk Reduction | Describes the three-step method for controlling machine risk |

6 | Information for Use | Covers instructions, warnings, and user information |

7 | Verification of Risk Reduction Measures | Describes how to confirm that the safety measures are effective |

What are the requirements of ISO 12100:2010?

To apply ISO 12100 correctly, organizations must follow a structured process that begins at the design stage and carries through testing and documentation. These requirements guide how hazards should be identified, risks evaluated, and controls implemented:

- Identify hazards that may arise during installation, use, cleaning, or maintenance of the machine.

- Perform a risk assessment to determine the severity and probability of each hazard.

- Apply inherently safe design measures to eliminate hazards where possible.

- Add technical protective measures if risks cannot be eliminated through design.

- Provide clear and understandable information for use, including warning signs and manuals.

- Document the results of the risk assessment and applied safety measures.

- Verify the performance of all risk-reduction measures through tests or analysis.

- Review and revise safety measures if there are changes in the machine or its application.

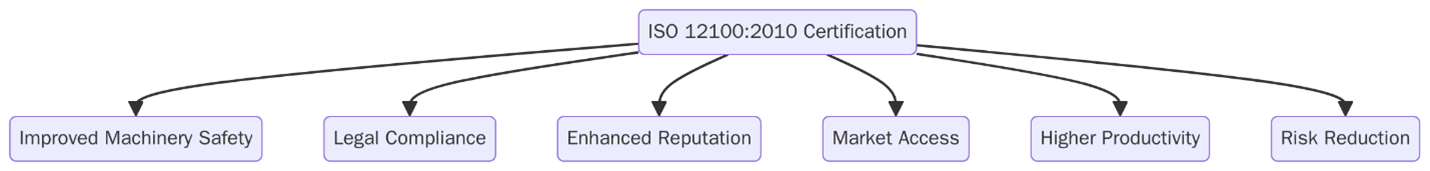

What are the benefits of ISO 12100:2010 Certification?

Companies that adopt ISO 12100 reduce their exposure to legal liability and improve workplace safety. It helps organizations embed risk control into design and reduce the likelihood of machine-related incidents. This structured approach supports compliance with international safety directives and improves client and user confidence. Below are the key benefits:

- Improved machine safety through design-focused hazard control that protects users at every stage

- Fewer workplace accidents by addressing safety issues before machines are built or installed

- Lower downtime and maintenance costs as systems are designed to minimize failure risks

- Better compliance with global safety laws, making machinery export-ready and regulation-aligned

- Clear documentation of design and safety steps which supports audits and certification

- Improved operator trust and usability with safety features built into day-to-day machine use

- More reliable maintenance procedures based on predictable and controlled machine functions

- Support for innovation by allowing safer integration of automation and new technologies

- Boosted market access as ISO 12100 is often recognized in procurement and safety evaluations

- Easier integration with ISO 9001 or API Q1 systems especially for quality and safety planning

As of now, ISO 12100 is increasingly used in industries introducing automation, cobots, and AI-assisted equipment. Reports from EU Machinery Safety authorities and Asia-Pacific standards bodies show that machinery with built-in safety features has 27% fewer downtime events and a 40% lower rate of operator injury. In North America, integration of ISO 12100 with ISO 13849 (Safety-related control systems) is becoming common in automotive and logistics plants. Globally, more OEMs are embedding ISO 12100 compliance into their product lifecycle planning to meet the growing demand for export-ready, safety-certified machines.

Eligibility Criteria

Any organization that designs or manufactures machinery can apply for ISO 12100 certification. It is suitable for OEMs, engineering firms, and contract manufacturers involved in mechanical design. Companies with existing ISO 9001 or API Q1 quality systems will find the transition smoother, as these systems already support structured documentation and verification steps.

Certification Process

Review:

Initial discussions focus on the current design process, hazard identification practices, and documentation.

Preparation:

Organizations prepare safety documentation, risk assessments, and evidence of design-level controls.

Stage 1 audit:

A preliminary check is conducted to review readiness, existing procedures, and technical records.

Stage 2 audit:

Detailed evaluation of the safety design strategy, testing records, and verification outcomes.

Certification decision:

Certification is granted if all requirements are fulfilled, with recommendations if needed.

Annual surveillance:

Ongoing annual reviews check for continued application of design principles and updated risk analysis.

Timeline for ISO 12100:2010 Certification

The full certification cycle typically takes 2 to 4 months. Companies that already follow formal design safety procedures may complete it faster. Organizations starting from scratch may need additional time to develop documentation and conduct necessary tests. Multi-site manufacturers or firms with complex machinery lines may require a phased audit approach.

What is the cost of ISO 12100:2010?

The cost of certification varies depending on the number of machines evaluated, complexity of design, scope of processes, and amount of supporting documentation available. Additional testing or on-site design verification may also affect costs. If ISO 12100 is bundled with ISO 9001 or other certifications, cost efficiencies may be possible.

How can Pacific Certifications Help?

Pacific Certifications audits organizations to ISO 12100:2010. We work with manufacturers, designers, and OEMs to assess how safety principles are applied in real machinery design. Our auditors check documentation, hazard assessment, verification records, and evidence of user-focused design.

We are accredited by ABIS and offer standalone or integrated audits with ISO 9001 or API Q1 systems. Our approach is practical and adapted to your production environment whether you are building industrial robots or packaging systems.

Training and Courses

Lead Auditor Training

Teaches how to assess safety in machinery design against ISO 12100 and prepare for formal audits.

Lead Implementer Training

Covers methods for integrating ISO 12100 in design workflows and creating risk assessment records.

Internal Auditor Training

Helps internal teams perform their own checks and maintain design documentation effectively.

Pacific Certifications provides accredited training programs. Contact support@pacificcert.com to schedule your training.

FAQs

How long does ISO 12100 certification last?

The certification is valid for three years with annual surveillance audits during that period.

Is this standard only for new machines?

No, it can also apply when redesigning or retrofitting existing machinery for improved safety.

Can it be combined with ISO 9001 audits?

Yes many manufacturers opt for integrated audits to save time and align both quality and safety.

Do we need to test every machine?

Not always. Testing can be done on representative models or designs based on risk level.

Is the standard suitable for small machine shops?

Yes small and mid-sized businesses can apply it as long as they have clear safety documentation.

Ready to get ISO 12100 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs