ISO Certifications for Drink Manufacturing Businesses, Requirements and Benefits

Drink manufacturing is an intricate industry requiring precision, safety measures and the highest quality standards. ISO certifications offer a strong framework for drink manufacturers to meet these expectations while maintaining global compliance.

Introduction to ISO Standards for Drink Manufacturing

ISO standards are globally recognized frameworks that ensure products and services meet safety and quality benchmarks. For the drink manufacturing sector, ISO certifications provide stringent guidelines that uphold the highest standards, from sourcing raw materials to production and distribution.

With increasing consumer demand for safe and high-quality beverages, complying with ISO certifications has become a hallmark of excellence. These certifications assure customers also enable businesses to stay competitive in the market.

If you are looking to elevate your drink manufacturing standards through ISO certification, contact us at support@pacificcert.com or call +91-8595603096. Let Pacific Certifications guide your journey to compliance and excellence.

Applicable ISO Standards for Drink Manufacturing

Drink manufacturers must comply with various ISO certifications depending on their specific needs and operational scope. Here are the most pertinent standards:

ISO 9001: Quality Management Systems (QMS):

ISO 9001 establishes guidelines for maintaining consistent product quality. It ensures manufacturers implement quality checks throughout their processes, enabling a customer-focused approach that minimizes defects and inefficiencies.

ISO 22000: Food Safety Management Systems (FSMS):

This standard is essential for drink manufacturers to manage and reduce food safety hazards. ISO 22000 integrates Hazard Analysis and Critical Control Points (HACCP) principles to enhance safety protocols, from ingredient sourcing to final packaging.

ISO 14001: Environmental Management Systems (EMS):

Sustainability is a growing concern in drink manufacturing. ISO 14001 provides a roadmap for reducing environmental impacts, optimizing resource use, and adhering to eco-friendly practices, helping businesses align with environmental regulations and customer expectations.

ISO 45001: Occupational Health and Safety (OHS):

Employee safety is paramount in manufacturing settings. ISO 45001 sets the framework for identifying workplace risks, implementing preventive measures, and fostering a culture of safety and health.

ISO 50001: Energy Management Systems:

Energy efficiency plays a crucial role in minimizing production costs. ISO 50001 enables drink manufacturers to adopt energy-saving strategies, reducing carbon footprints and aligning with global sustainability goals.

ISO 17025: Testing and Calibration Laboratories:

This certification is vital for manufacturers conducting in-house testing and quality analysis. It ensures the accuracy and reliability of laboratory results, critical for quality assurance in beverage production.

ISO 31000: Risk Management:

Managing risks is integral to maintaining operational efficiency. ISO 31000 helps organizations identify, analyze, and mitigate risks related to production, supply chain, and market dynamics.

Click here to find out more applicable standards to your industry

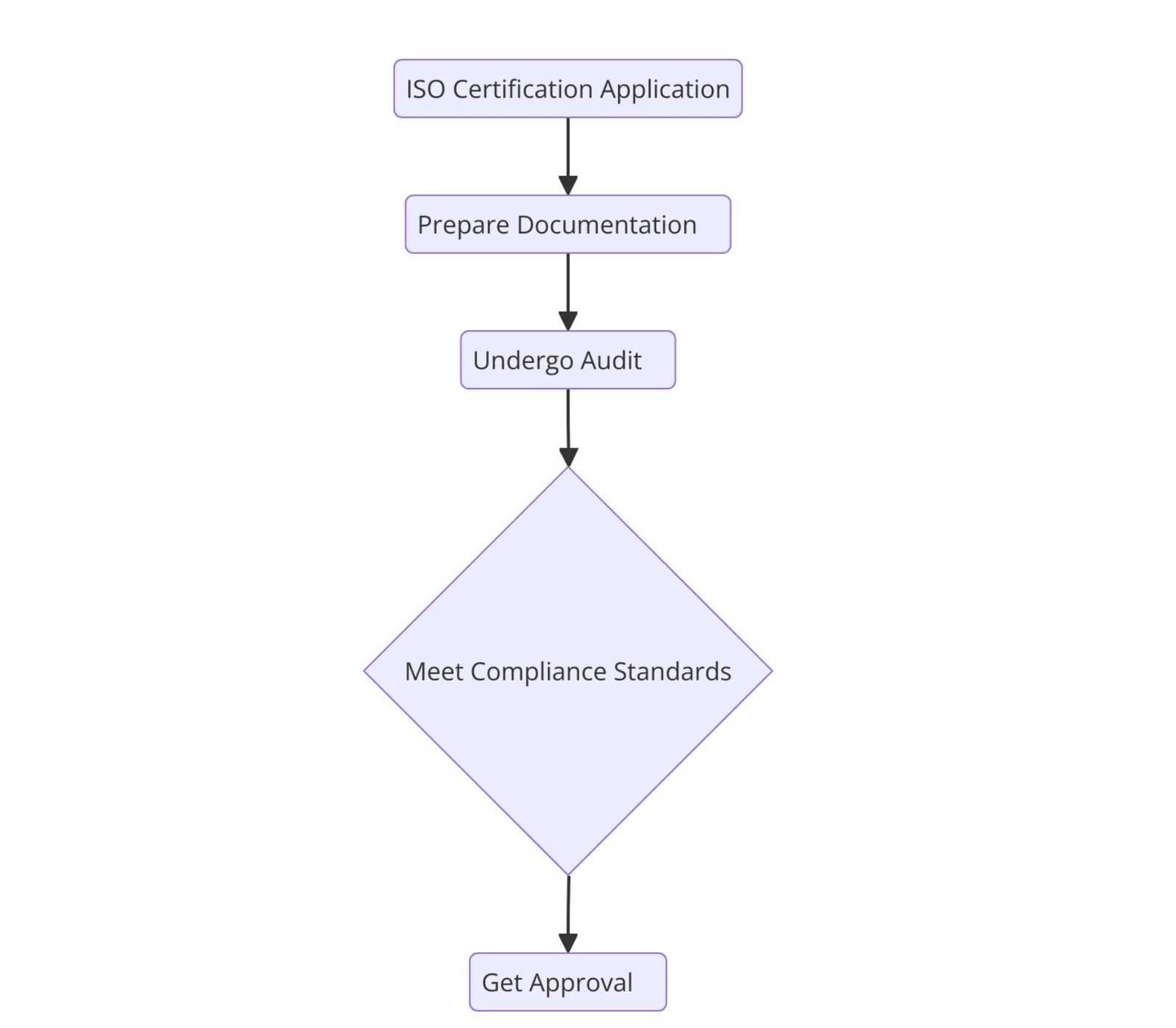

At Pacific Certifications, we specialize in auditing and issuing ISO certifications tailored to drink manufacturing. With a team of experienced auditors and a commitment to integrity, we ensure your organization meets all certification requirements seamlessly. Our expertise extends to ISO standards such as ISO 9001, ISO 22000, and ISO 14001, among others.

We support manufacturers by identifying gaps during audits and guiding them toward certification compliance. By choosing Pacific Certifications, you align with a trusted partner recognized globally for excellence in certification services.

Looking for ISO certification for drink manufacturing? Contact our experts at support@pacificcert.com or call +91-8595603096 for professional audit and certification services.

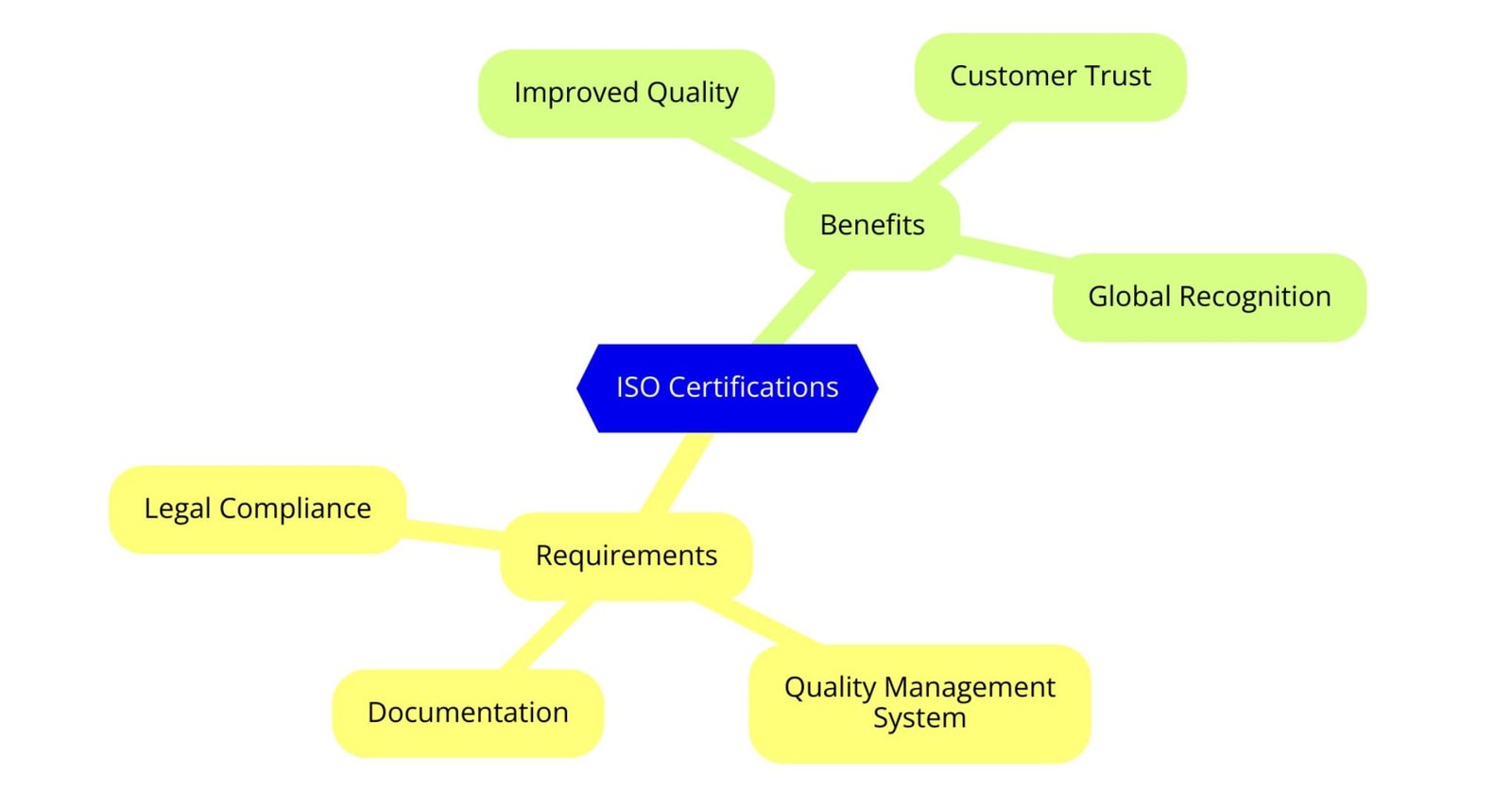

Requirements of ISO Certifications for Drink Manufacturing

Meeting ISO certification requirements involves understanding the specific expectations of each standard. Below, we outline the essential requirements for the key ISO standards applicable to drink manufacturing:

ISO 9001: Quality Management Systems (QMS) Requirements

- Establishment of a Quality Policy: Develop a clear policy aligned with organizational goals.

- Defined Processes: Document and implement processes for production, quality control, and customer interactions.

- Customer Focus: Monitor customer feedback and satisfaction levels to enhance the quality of services.

- Risk-Based Thinking: Identify and address risks and opportunities that could impact product quality.

- Internal Audits: Conduct regular audits to ensure compliance and identify areas for improvement.

- Management Review: Periodically review the QMS to align it with business objectives.

ISO 22000: Food Safety Management Systems (FSMS) Requirements

- Hazard Analysis and Critical Control Points (HACCP): Implement HACCP to identify and manage food safety hazards.

- Pre-Requisite Programs (PRPs): Establish hygiene and sanitation practices to maintain safe production environments.

- Traceability Systems: Ensure the ability to track ingredients and finished products throughout the supply chain.

- Emergency Preparedness: Develop plans to handle food safety crises effectively.

- Communication Protocols: Maintain clear communication with stakeholders about food safety standards.

ISO 14001: Environmental Management Systems (EMS) Requirements

- Environmental Policy: Define and communicate a policy outlining your commitment to sustainability.

- Identification of Environmental Aspects: Analyze how your processes interact with the environment, including energy use and waste generation.

- Compliance Obligations: Identify and adhere to applicable environmental laws and regulations.

- Operational Controls: Implement controls to manage significant environmental aspects, such as reducing emissions or waste.

- Monitoring and Measurement: Track environmental performance metrics and improve where necessary.

ISO 45001: Occupational Health and Safety Management Systems (OHSMS) Requirements

- Hazard Identification: Identify workplace hazards related to equipment, processes, and environments.

- Risk Assessment: Analyze and prioritize risks to establish preventive and corrective actions.

- Worker Participation: Engage employees in safety measures and decision-making processes.

- Legal Compliance: Adhere to occupational health and safety regulations.

- Emergency Preparedness: Establish plans to handle accidents, spills, or other emergencies effectively.

ISO 50001: Energy Management Systems (EnMS)

- Energy Policy Development: Create a policy outlining energy efficiency goals.

- Energy Planning: Analyze energy usage patterns and identify opportunities for savings.

- Energy Performance Indicators (EnPIs): Develop metrics to track energy efficiency progress.

- Operational Controls: Implement measures to optimize energy consumption in production processes.

- Continual Improvement: Review energy performance regularly and adjust strategies for better results.

How These Requirements Align with Drink Manufacturing?

Each standard addresses specific aspects critical to drink manufacturing:

- ISO 9001 ensures consistent product quality and customer satisfaction.

- ISO 22000 guarantees the safety of drinks from raw materials to distribution.

- ISO 14001 and ISO 50001 promote environmental responsibility and energy efficiency, increasingly important in 2024’s sustainability-driven market.

- ISO 45001 safeguards employees working in potentially hazardous environments.

- ISO 17025 ensures laboratory accuracy for beverage quality testing.

- ISO 31000 helps mitigate operational, financial, and supply chain risks.

Drink manufacturers adhering to these standards can achieve operational excellence, regulatory compliance, and customer trust. For seamless ISO certification, Pacific Certifications is here to assist. Contact us at support@pacificcert.com for more information.

Benefits of ISO Certifications for Drink Manufacturing

Implementing ISO certifications in drink manufacturing offers a multitude of advantages, including:

Product Safety and Quality: ISO certifications ensure that products meet stringent safety and quality benchmarks, fostering consumer trust.

Market Competitiveness: Certified manufacturers stand out in a crowded market, appealing to customers who prioritize safety and quality.

Regulatory Compliance: ISO standards help organizations comply with international and local regulations, reducing the risk of legal issues or product recalls.

Efficiency: Streamlined processes and improved resource management result in cost savings and increased production efficiency.

Environmental Responsibility: ISO 14001 and ISO 50001 certifications underscore a company’s commitment to sustainability, which is increasingly valued by consumers.

Employee Safety: ISO 45001 fosters a safe working environment, boosting employee morale and productivity.

Global Recognition: Being ISO-certified signals a company’s adherence to international standards, facilitating entry into global markets.

Market Trends

In this year, the drink manufacturing industry is witnessing a surge in demand for functional beverages, including plant-based drinks and health-focused alternatives. Consumers are more discerning, with an increased focus on safety, sustainability, and transparency. ISO certifications play a pivotal role in meeting these expectations.

Research highlights that companies investing in certifications like ISO 22000 and ISO 14001 are better positioned to capitalize on these trends, gaining customer trust and loyalty. Additionally, stricter environmental regulations are compelling manufacturers to adopt standards like ISO 50001 to reduce their carbon footprint.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Drink Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Drink Manufacturing

What are ISO certifications for drink manufacturing?

ISO certifications are globally recognized standards that ensure quality, safety, and efficiency in drink manufacturing processes.

Which ISO certifications are essential for drink manufacturing?

Key certifications include ISO 9001 (Quality Management), ISO 22000 (Food Safety), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety).

How can ISO certifications benefit drink manufacturers?

They improve product quality, enhance safety, ensure regulatory compliance, reduce costs, and foster sustainability.

Why choose Pacific Certifications for ISO audits?

Pacific Certifications offers expert audit and certification services, ensuring compliance with ISO standards efficiently and effectively.

Are ISO certifications mandatory for drink manufacturers?

While not legally mandatory, ISO certifications are crucial for meeting industry standards, gaining consumer trust, and expanding into global markets.

How long does it take to obtain an ISO certification?

The timeline depends on the organization’s size and readiness. It typically ranges from a few weeks to several months.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs