Introduction to ISO Certifications in Butter Production

The butter production industry depends heavily on quality control, food safety, hygiene practices, and traceability. For producers looking to expand market access and meet global expectations, ISO Certifications for Butter Production Businesses serve as a reliable way to bring structure and global credibility to their operations.

ISO standards are designed to help producers align with food-grade safety, consistent manufacturing, and environmental care. With consumer awareness growing, many dairy and butter processing companies are turning to internationally accepted standards to improve production consistency and stay relevant across markets.

Looking to certify your butter production facility? Pacific Cert offers third-party ISO audits for food and dairy processors. Email: support@pacificcert.com

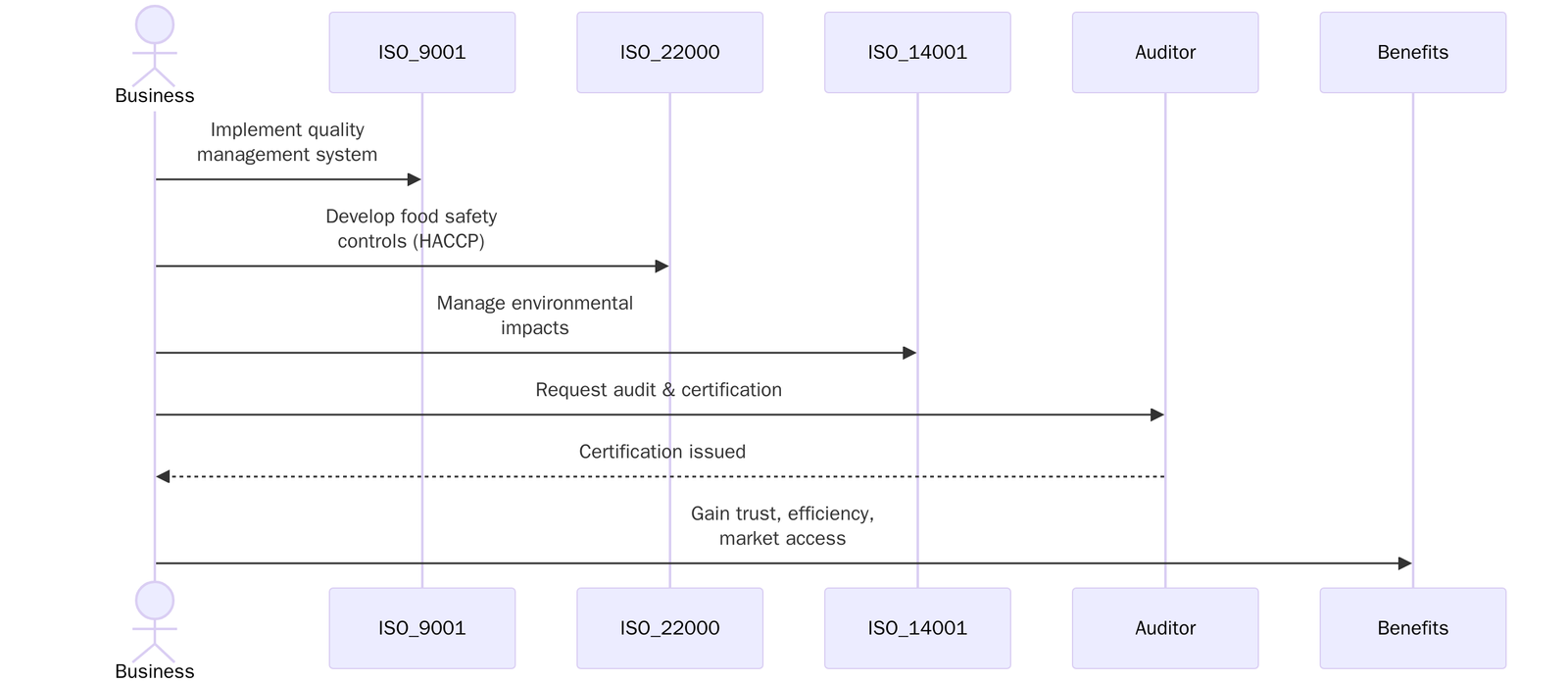

Applicable ISO Standards for Butter Production Businesses

Butter production businesses fall under the broader dairy and food processing industry. These are the ISO standards that directly apply to their day-to-day operations:

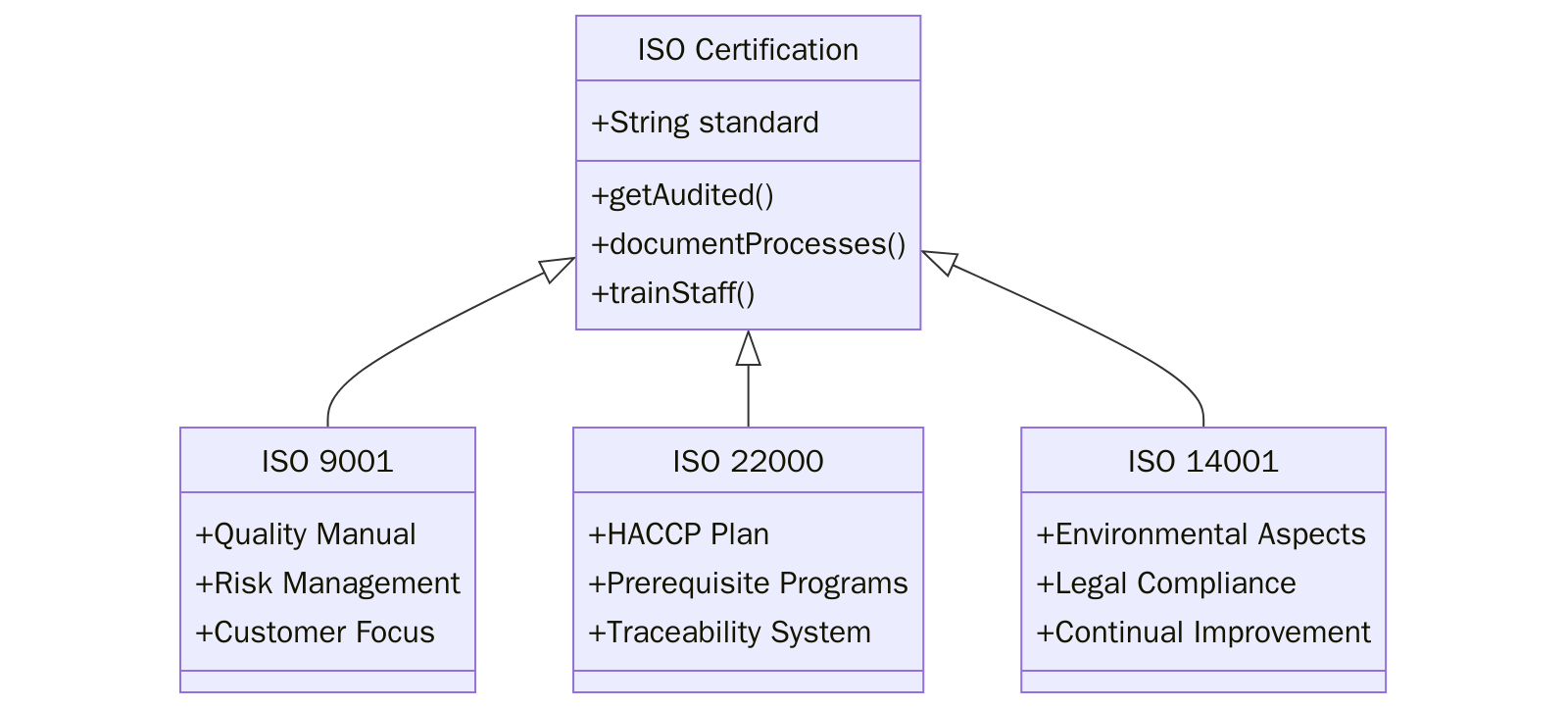

ISO 22000: Food Safety Management Systems

This standard outlines a food safety management system that is suitable for any organization in the food chain. It is critical for butter manufacturers to manage hazards and maintain a safe production environment.

ISO 9001: Quality Management Systems

Applicable across industries, ISO 9001 helps ensure consistent quality, process documentation, and continuous improvement throughout production lines.

ISO 14001: Environmental Management Systems

For butter plants looking to manage energy use, waste, and water, ISO 14001 allows better control of environmental impacts.

ISO 45001: Occupational Health and Safety Management Systems

This applies to worker safety within the factory, especially where machinery, boilers, or chilling equipment is used in production.

ISO 50001: Energy Management Systems

Butter production involves cooling, churning, and pasteurization — all of which consume energy. This standard helps monitor and reduce energy consumption.

ISO 22005: Traceability in the Feed and Food Chain

Ensures traceability from raw milk to packaged butter, which is key for food safety recalls and consumer trust.

ISO 17025: Testing & Calibration Laboratories:

For butter manufacturers, testing parameters like moisture content, fat levels, and microbial safety are critical. ISO 17025 ensures laboratories maintain high standards in testing butter quality.

Requirements of ISO Certifications for Butter Production

Butter plants must follow specific process-based steps under each standard. Below are the main requirements:

ISO 22000 – Food Safety Management System

- Conduct hazard analysis for biological, chemical, and physical risks.

- Establish PRPs (Prerequisite Programs) for sanitation, hygiene, and storage.

- Maintain food safety plans and critical control points (CCPs).

- Ensure internal audits and corrective actions are documented.

ISO 9001 – Quality Management System

- Create quality objectives for production, packaging, and customer satisfaction.

- Define roles, responsibilities, and internal process flows.

- Use documented procedures for quality control and batch monitoring.

- Conduct periodic management reviews and audits.

ISO 14001 – Environmental Management System

- Identify key impacts: water usage, dairy waste, refrigeration.

- Set measurable objectives to manage those impacts.

- Use controls to monitor emissions and chemical usage.

- Comply with applicable environmental laws and permits.

ISO 45001 – Occupational Health and Safety

- Identify physical and chemical hazards from butter churners and cleaning agents.

- Monitor machinery and ergonomics in the work environment.

- Implement incident tracking and safety drills.

- Involve employees in safety reviews and feedback.

ISO 50001 – Energy Management System

- Measure energy usage in chilling systems and motors.

- Record energy baselines and identify saving opportunities.

- Set targets for reducing consumption during peak loads.

- Review energy performance data periodically.

ISO 22005 – Traceability in Feed and Food Chain

- Maintain records from raw milk sourcing to final packaging.

- Create a traceability system to identify batches.

- Ensure quick response capabilities in case of recalls.

- Use labeling that supports tracking at each process stage.

FSSC 22000 – Food Safety System Certification

- Include ISO 22000 system along with ISO/TS 22002-1 (PRPs).

- Address transport, cleaning, and personnel hygiene in detail.

- Maintain additional documentation required by GFSI.

- Undergo certification audits with extended scope.

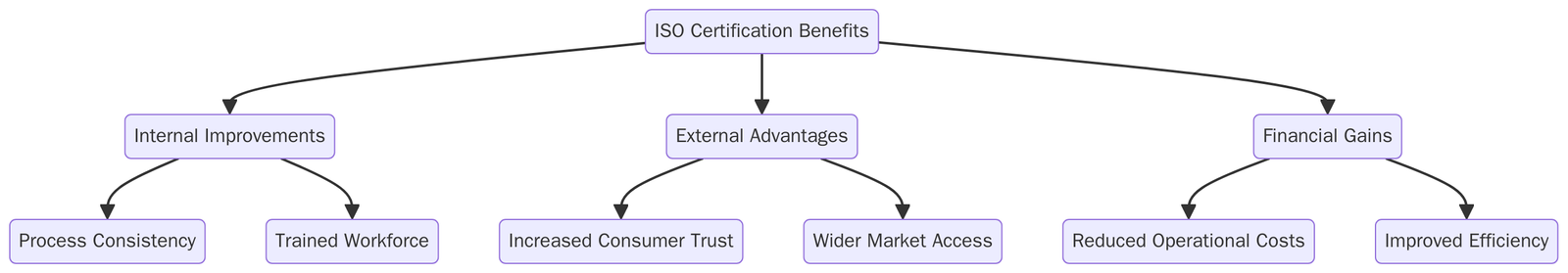

Benefits of ISO Certifications for Butter Production

Read the points below to understand what your business can gain:

- Helps improve product consistency and reduce batch-to-batch variation

- Strengthens food safety and reduces risk of contamination events

- Increases trust from buyers, distributors, and supermarket chains

- Allows access to global markets with recognized certification

- Streamlines documentation and internal quality checks

- Promotes staff training and operational clarity across departments

- Offers better control of waste, energy, and refrigeration processes

- Supports traceability which is vital for dairy recalls and audits

- Encourages safer work environments for machine-heavy operations

The butter production industry is experiencing noticeable changes driven by global trade, health-conscious consumers, and demand for traceable food chains. There is a growing shift toward low-fat and organic butter variants which has led producers to reassess their quality and food safety controls.

Many manufacturers are investing in ISO 22000 and FSSC 22000 to meet buyer expectations in regions like the EU and Gulf countries. Additionally, environmental concerns around dairy waste and energy use have pushed producers to adopt ISO 14001 and ISO 50001.

Training and Courses

To prepare for certification, your staff may benefit from standard-specific training. Here are the most relevant options:

ISO 22000 Lead Auditor Training – For professionals leading food safety audits within or outside the company.

ISO 9001 Internal Auditor Training – Covers documentation, internal reviews, and process audits for quality control.

ISO 45001 Implementer Training – Useful for safety officers working in dairy facilities and industrial setups.

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 22000, ISO 9001, or FSSC 22000 training, our team is equipped to help you. Contact us at support@pacificcert.com

FAQs: ISO Certifications for Butter Production

Which ISO is best for butter production?

ISO 22000 is the most applicable, followed by ISO 9001 and FSSC 22000 for export-oriented plants.

Can Pacific Certifications help with implementation?

No, Pacific Certifications only provides audits and certification. For gap analysis or setup, a consultant or internal team is needed.

Is ISO certification mandatory for food producers?

It is not mandatory but often required by retailers, suppliers, and international trade partners.

How often is the certification renewed?

Certificates are valid for three years, with yearly surveillance audits to maintain certification.

Can small butter producers get ISO certified?

Yes. The system is scalable, and certification bodies like Pacific Certifications tailor audits to business size and scope.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs