What is ISO 3834?

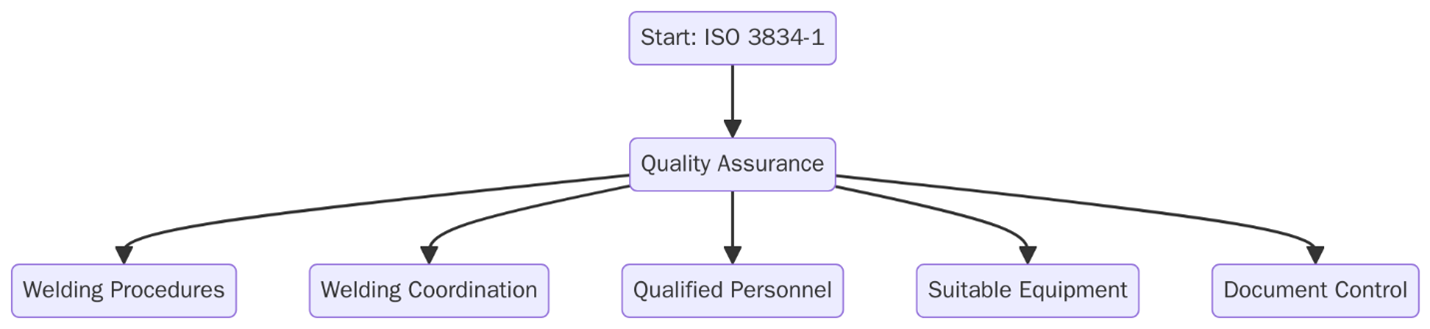

ISO 3834-1 is part of a multi-part standard that defines quality requirements for fusion welding of metallic materials. It serves as the core document in the ISO 3834 series and lays out general principles applicable to all levels of welding quality. The standard is widely used in sectors that depend on welded components such as construction, pressure vessels, railways, automotive, energy and marine industries.

Fusion welding directly affects the strength and performance of metal structures. ISO 3834-1 provides companies with a structured method to manage welding processes through defined procedures, qualified personnel and traceable documentation. It offers a way to select the right level of quality for each project and helps apply consistent welding practices throughout production, whether in manufacturing, repair or complex engineering environments.

To begin your ISO journey or schedule an audit contact us at support@pacificcert.com

Purpose

The purpose of ISO 3834-1 is to define the criteria an organization should follow to control the quality of fusion welding processes. It helps companies avoid welding defects, reduce failures in service, and meet design and customer requirements. This standard fills the gap between product-specific welding requirements and broader quality systems like ISO 9001. It ensures that welding controls are not overlooked in general quality management systems and that welding-related risks are minimized.

Scope and Applicability

ISO 3834-1 applies to any industry where fusion welding is used in the manufacture, repair, or modification of metallic products. It can be implemented by manufacturers of structural steel, boilers, pipelines, bridges, offshore platforms, ships, and heavy machinery.

It is also useful for subcontractors who carry out welding as part of large engineering projects. Whether a company works in shipbuilding, power generation, railcar production, or oil and gas fabrication, It allows them to select a suitable level of welding quality assurance and match it with their technical needs and customer expectations.

Key Definitions

Fusion Welding – A process where metal pieces are joined by heating them to their melting point, with or without filler.

Welding Coordination – The oversight and management of welding-related tasks by a qualified person to ensure welding quality.

Weldability – The ability of a material to be welded under specific conditions to perform as intended.

Non-conformance – Any deviation from specified welding procedures, workmanship, or documentation.

Quality Level – The degree of control applied to the welding process, ranging from simple inspection to complete process management.

Clause-wise Structure of ISO 3834 certification

Clause Number | Title | Description |

1 | Scope | Describes the industries and applications for which the standard is used |

2 | Normative References | Lists other ISO documents required for implementing ISO 3834-1 |

3 | Terms and Definitions | Provides terms used throughout the standard and their meanings |

4 | Principles for Welding Quality Management | Introduces quality requirements and guidance for managing welding quality |

5 | Selection of Quality Requirement Level | Explains how to choose between Part 2, 3, or 4 depending on product type |

6 | Integration with ISO 9001 | Details how ISO 3834 can complement an ISO 9001-certified system |

What are the requirements of ISO 3834?

To successfully implement ISO 3834 certification, an organization must take structured actions that connect welding practices to quality expectations. These steps involve managing documentation, qualifying personnel, and validating processes. The standard requires practical controls that can be followed on the shop floor and verified during audits. The following are the key requirements that companies need to address when applying ISO 3834-1 in their operations:

- Identify the types of welded products your organization manufactures or repairs.

- Determine which level of quality requirement (from Part 2, 3, or 4) is suitable for your welding activities.

- Appoint qualified welding coordinators responsible for overseeing welding operations and documentation.

- Prepare written welding procedures and ensure that they are validated through procedure qualification tests.

- Ensure that welding personnel, including welders and inspectors, are properly trained and certified.

- Implement inspection and testing processes to monitor weld quality before, during, and after production.

- Maintain full traceability for materials, welding consumables, and inspection results through documentation.

- Perform internal audits to assess compliance with the selected level of ISO requirements.

What are the benefits of ISO 3834 Certification?

By adopting ISO 3834, companies can strengthen their welding control systems and improve product reliability. The standard supports safe construction and long-term service life of welded products across industrial sectors. Below are the main benefits companies can expect after implementing and certifying to ISO 3834:

- Improved weld quality through consistent procedures and certified personnel

- Fewer weld defects due to documented process validation and inspections

- Greater customer trust based on adherence to international welding requirements

- Better risk control for failure-prone operations like pressure vessels or load-bearing structures

- Integration with ISO 9001 where welding-specific controls are not otherwise addressed

- Wider market access when bidding for government or international contracts

- Reduced rework and warranty claims by preventing weld-related failures in production

- Better supplier evaluation through consistent auditing of subcontractor welding systems

The demand for ISO certified companies has increased globally due to tighter expectations in infrastructure, defense, energy, and transportation sectors. Countries like Germany, South Korea, and India have aligned procurement systems to accept ISO 3834 as proof of welding quality management. With the rise of offshore wind, hydrogen pipelines, and electric rail manufacturing, this standard is being adopted not only in fabrication yards but also among OEMs and contract manufacturers. Welding audits under ISO are now considered a competitive differentiator in high-risk and export-heavy industries.

Eligibility Criteria

ISO 3834-1 can be applied by manufacturers, fabricators, repair workshops, or contractors involved in fusion welding of metals. It suits both large production facilities and small repair workshops. Having an existing ISO 9001 or API Q1 quality system can help as it provides a foundation for integrating welding-specific quality controls. However, it is not mandatory.

Certification Process: ISO 3834

Review

A preliminary review is conducted to understand welding operations, existing systems, and applicable welding codes or standards.

Preparation

The organization prepares the necessary documents such as welding procedure specifications (WPS), welder qualification records, and inspection plans.

Stage 1 Audit

Auditors verify the documented procedures, welding personnel qualifications, and readiness for full assessment.

Stage 2 Audit

On-site audit to evaluate how welding activities are performed, inspected, and recorded. Auditors may review production samples, test results, and welder performance.

Certification Decision

If all processes meet the standard, certification is issued for a period of three years.

Annual Surveillance

Yearly audits are conducted to confirm the ongoing conformity with ISO 3834-1 and to verify updates or changes in welding operations.

Timeline for ISO 3834 Certification

The certification timeline typically ranges from 4 to 10 weeks depending on how ready your documentation is and the size of your welding operation. If you already have documented welding procedures and certified personnel, the process moves faster. Larger facilities with multiple welding processes or subcontractors may require more audit days.

What is the cost of ISO 3834?

Certification costs vary based on the number of welding operations, complexity of products, testing and inspection needs, and whether the audit is standalone or part of a combined audit with ISO 9001 or API Q1. Organizations with established welding documentation and traceability systems may reduce audit time and cost.

How can Pacific Certifications Help?

Pacific Certifications supports manufacturers and fabricators through ISO 3834-1 certification audits and training. Our team focuses on practical evaluations and aligns audits with real welding shop practices.

- We audit welding operations across industries like construction, energy, shipbuilding, and machinery to ISO 3834-1 requirements

- Our audits are practical—we review your welding procedures, welder qualifications, inspection reports, and WPS/PQR records

- We offer combined audits with ISO 9001 or API Q1 if welding is part of a broader quality system

- We are accredited by ABIS, which means our certification processes meet international standards of audit quality

- We provide value-based assessments without consulting or writing documents—we focus only on certification and surveillance

- Our audit teams understand welding codes such as ASME, EN, and AWS, which helps during technical review

- We support both new applicants and recertification clients, with flexible audit plans based on your welding operations

Training and Courses

Lead Auditor Training

Covers ISO 3834 audit methods, documentation review, and reporting techniques for external audits.

Lead Implementer Training

Provides knowledge on building and managing a welding quality system internally using ISO 3834 parts.

Internal Auditor Training

Prepares your internal team to assess welding activities and maintain documentation before external audits.

Pacific Certifications provides accredited training programs. Contact support@pacificcert.com to schedule your training.

FAQs

Is ISO 3834 mandatory for welding companies?

It depends on industry or customer requirements. Some sectors like railways or pressure equipment require it as part of compliance.

Can ISO 3834 be used with ISO 9001?

Yes. ISO 3834-1 can be integrated into ISO 9001 to address welding-specific controls.

How long does the ISO 3834 certification remain valid?

ISO 3834-1 certification is valid for three years with annual surveillance audits.

Do we need to test every weld?

Not always. The standard requires appropriate testing depending on risk level and product type, which can include visual, NDT, or destructive tests.

What size companies can apply ISO 3834 certification?

Any company regardless of size can implement ISO 3834-1 if involved in fusion welding. It suits small fabrication shops and large engineering firms alike.

Ready to get ISO 3834 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs