What is ISO 26262?

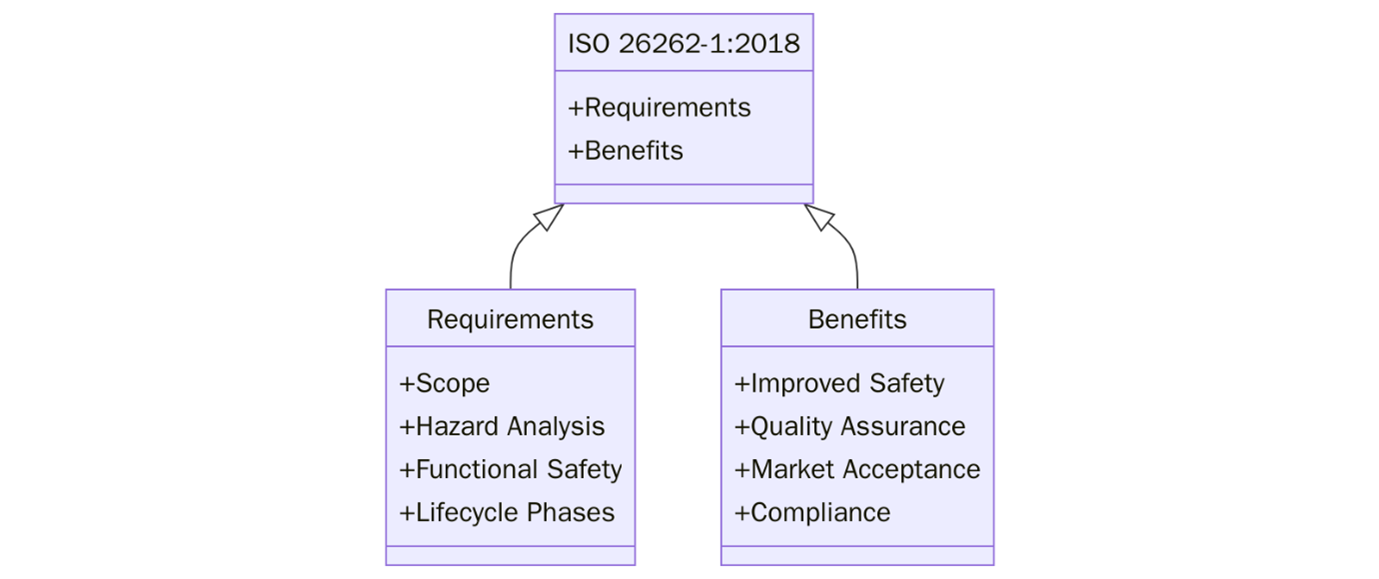

ISO 26262-1:2018 is the first part of the internationally recognized ISO 26262 standard series, specifically dedicated to defining the vocabulary and terminology used throughout the standard. It focuses on functional safety in electrical and electronic systems within road vehicles, addressing safety-related systems in passenger cars, trucks and buses.

Part 1 provides precise definitions for over 100 technical terms essential for interpreting and applying Parts 2 to 12. These definitions ensure a common understanding among engineers, project managers and safety assessors working on automotive functional safety.

Clear, consistent terminology is critical in an industry where misunderstanding safety terms could result in product failure or loss of life.

Looking to train your team or build documentation aligned with ISO 26262? Contact us at support@pacificcert.com!

Scope and Applicability

ISO 26262-1:2018 applies to organizations involved in the design, development, and maintenance of road vehicle systems involving electrical and electronic components, including:

- Automotive OEMs and Tier 1/Tier 2 suppliers

- Embedded software developers

- Autonomous vehicle system designers

- Powertrain and chassis control system engineers

- Safety managers and compliance officers

The vocabulary defined in Part 1 is relevant to all other parts of ISO 26262 (Parts 2–12), making it a foundational component for all activities related to functional safety engineering in the automotive domain.

What is the purpose of ISO 26262?

The main purpose of ISO 26262-1 is to ensure clarity and unambiguous communication of terms related to functional safety. It eliminates confusion around complex technical concepts by providing:

- Precise definitions of functional safety terms

- Harmonized language across the entire ISO series

- Support for internal training, project documentation, and audits

- Alignment with international safety standards such as IEC 61508 (on which ISO 26262 is based)

Without a shared vocabulary, implementing functional safety practices across multinational teams or supply chains would be extremely difficult.

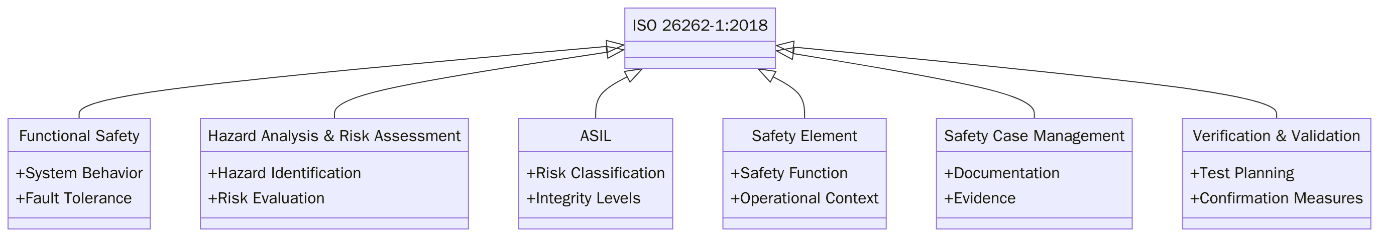

Key Terms Defined

Here are some of the critical terms explained in Part 1 of the standard:

- Functional Safety: Absence of unreasonable risk due to hazards caused by malfunctioning behavior of electrical/electronic systems.

- Hazard: A potential source of harm arising from a malfunction of a system.

- ASIL (Automotive Safety Integrity Level): A risk classification scheme (A–D) that determines the safety requirements based on severity, exposure, and controllability.

- Safety Goal: A top-level safety requirement resulting from a hazard analysis.

- Item: A system or array of systems that implements a function at the vehicle level.

- Fault vs. Failure: A fault is the cause of a failure; failure is the termination of the ability of a system to perform its intended function.

- Safe State: A system condition that is recognized as not hazardous under defined conditions.

- Freedom from Interference: The property that ensures one software or hardware element does not adversely affect another.

- Dependent Failures: Multiple failures that have a common cause or cascading effect.

These terms form the linguistic backbone of the entire functional safety framework.

Need help understanding how these terms apply to your project? Contact us at support@pacificcert.com!

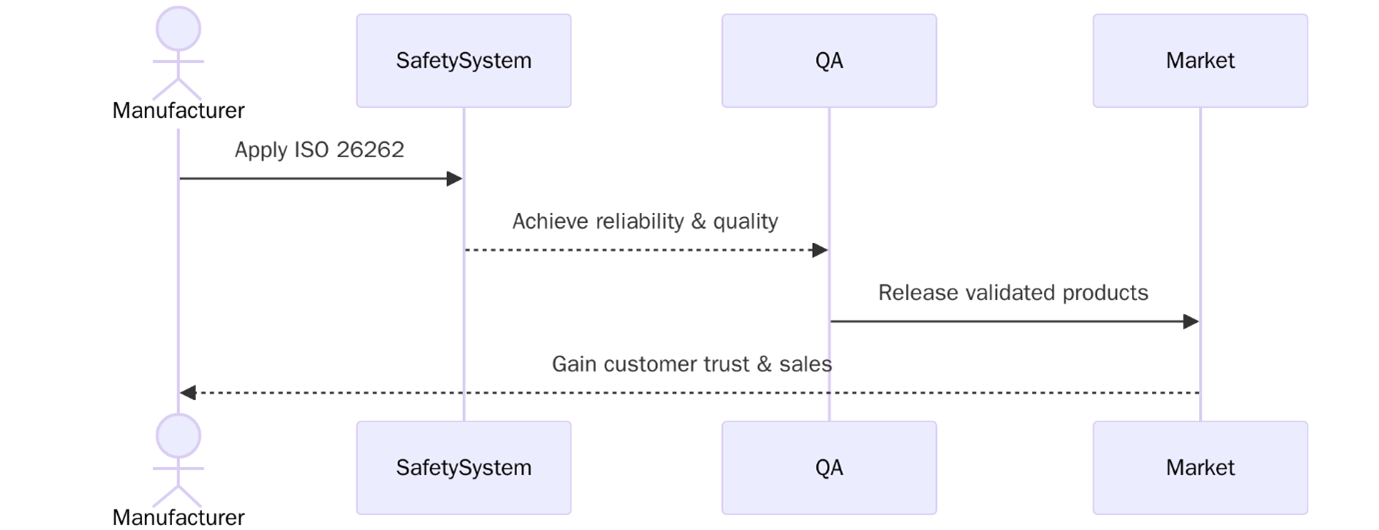

How to Use ISO 26262 in Your Projects?

Though ISO 26262-1 is essential for correctly interpreting all other parts of ISO 26262. Here’s how to use it effectively:

- Use it as the core material in functional safety training programs for engineers, software developers, and project managers.

- Standardize vocabulary across safety plans, safety case documentation, FMEA/FMEDA analyses, and requirements specifications.

- Ensure all suppliers, auditors, and external development teams use the same terminology for consistency and compliance.

- Promote a common language to reduce misinterpretation and enhance safety culture across departments.

Need help creating internal training or documentation aligned with ISO 26262-1? Contact us at support@pacificcert.com.

Relation to Other Parts

It provides definitions used in the following parts of the standard:

Part | Title |

Part 2 | Management of Functional Safety |

Part 3 | Concept Phase |

Part 4 | Product Development: System Level |

Part 5 | Product Development: Hardware Level |

Part 6 | Product Development: Software Level |

Part 7 | Production, Operation, Service, and Decommissioning |

Part 8 | Supporting Processes |

Part 9 | ASIL-Oriented and Safety-Oriented Analysis |

Part 10 | Guidelines on ISO 26262 |

Part 11 | Guidelines on Applications to Semiconductors |

Part 12 | Adaptation for Motorcycles |

Understanding the definitions in Part 1 is necessary for correct application of safety analysis and system design per these parts.

What are the benefits of ISO 26262?

- Using a common vocabulary reduces misunderstandings and project delays caused by ambiguous terms.

- Well-defined terminology supports traceability, audit trails, and evidence in functional safety assessments.

- Clearly defined safety-critical terms help avoid errors in risk analysis, system design, and verification.

- Suppliers and OEMs speaking a “common language” improve system integration and reduce quality issues.

- Acts as a base document for onboarding engineers and safety specialists in the automotive industry.

- Maintains compatibility with general functional safety standards used across other sectors.

Recently, the automotive industry is experiencing rapid transformation with the rise of autonomous driving, advanced driver-assistance systems (ADAS), and software-defined vehicles. These developments increase system complexity, making functional safety and consistent safety vocabulary, more critical than ever.

Regulatory bodies in the EU, U.S., Japan, and China are now referencing ISO as part of vehicle type approvals and product liability defense. According to a 2024 report by the Automotive Safety Consortium, over 70% of safety incidents in EV and ADAS systems were linked to misunderstanding or incorrect implementation of safety terminology or roles, highlighting the relevance of this standard.

Don’t let inconsistent language compromise your safety case, get expert guidance at support@pacificcert.com!

How Pacific Certifications Can Help?

At Pacific Certifications, we offer comprehensive support for ISO 26262 implementation, including:

- Functional safety training

- Documentation and safety case development

- Audits and readiness assessments

- Supplier and stakeholder compliance alignment

- Integration with ISO 9001, ASPICE, and cybersecurity standards (ISO/SAE 21434)

Whether you’re working on ECUs, battery management systems, or automated driving platforms, we can guide you through the functional safety landscape.

Start your ISO compliance journey, contact support@pacificcert.com!

FAQ on ISO 26262

Is ISO 26262-1 certifiable?

It is a foundational vocabulary reference and is not a certifiable part of the standard.

Who should use ISO 26262-1?

Safety engineers, developers, auditors, and managers involved in functional safety across vehicle development.

Does ISO 26262 apply to electric and autonomous vehicles?

Yes, ISO 26262 is applicable to all road vehicles with electrical/electronic safety-related systems, including EVs and AVs.

How does ISO 26262-1 relate to ISO/SAE 21434?

ISO 26262-1 provides definitions for functional safety, while ISO/SAE 21434 focuses on cybersecurity. Both complement each other in vehicle development.

Is ISO 26262 mandatory?

While not legally mandatory, it is widely adopted and expected by regulators and OEMs for liability protection and market access.

Ready to get certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs