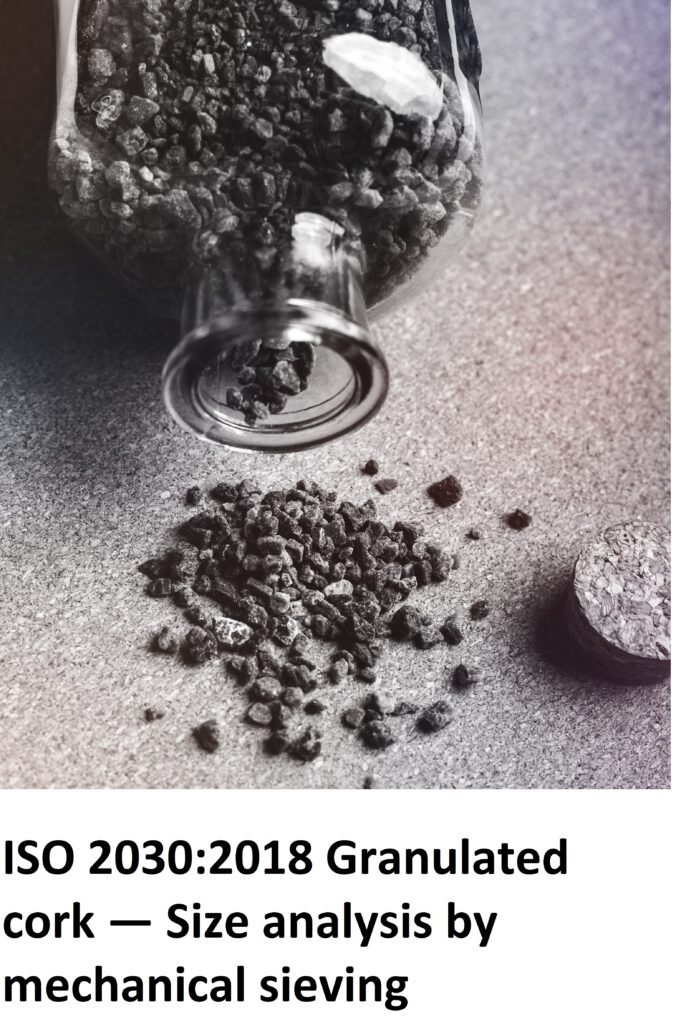

What is ISO 2030:2018 Granulated cork — Size analysis by mechanical sieving?

ISO 2030:2018 specifies a method for the determination of the particle size distribution of granulated cork by mechanical sieving.

In this method, granulated cork oasses through a series of sieves of different mesh sizes, and the amount of material retained on each sieve is measured. The results are then used to calculate the particle size distribution of the granulated cork.

This standard applies to all types of granulated cork, regardless of their origin or intended use. It is particularly relevant for quality control and product specification purposes in industries that use granulated cork. Such as the construction and automotive sectors.

Requirements of ISO 2030:2018:

ISO 2030:2018 specifies the requirements for the determination of the particle size distribution of granulated cork by mechanical sieving. Thus, the standard outlines the following requirements:

Apparatus: The equipment used for mechanical sieving should comply with the requirements specified in the standard, including the type of sieve, sieve shaker, and measuring devices.

Sampling: The sample of granulated cork to be analyzed should be taken in accordance with ISO 186. Also, the size of the sample should be appropriate for the equipment used.

Procedure: The standard provides detailed instructions for the mechanical sieving procedure, including the setup and operation of the equipment, the duration of the sieving process, and the cleaning and drying of the sieves.

Calculation of results: The amount of material retained on each sieve should be determined. Also, the particle size distribution should be calculated using the appropriate formulas specified in the standard.

Reporting of results: The results of the analysis should be reported in accordance with ISO 14688-1. Including the particle size distribution curve, median particle size, and uniformity coefficient.

Therefore, ISO 2030 also includes guidelines for the interpretation of the particle size distribution results and recommendations for the application of the method in different industries.

Benefits of this standard:

ISO 2030:2018 provides a standardized method for the size analysis of granulated cork by mechanical sieving. Thus, The benefits of this standard include:

Standardization: ISO 2030 provides a standardized method for the size analysis of granulated cork, ensuring that measurements are consistent across different laboratories and manufacturers.

Quality control: By using a standardized method for size analysis, manufacturers can ensure that their products meet the required specifications and quality standards.

Efficiency: The use of a standardized method for size analysis can improve the efficiency of manufacturing processes by reducing the need for repeated testing and rework.

Cost-effectiveness: Standardization of testing methods can lead to cost savings through improved efficiency and reduced waste.

Better understanding of the product: By providing a standardized method for size analysis, ISO 2030 can improve the understanding of the properties of granulated cork and its suitability for various applications.

Who needs ISO 2030:2018?

ISO 2030:2018 is intended for manufacturers, distributors, and users of granulated cork who need to determine the particle size distribution of the material. It can also be used by testing laboratories and organizations involved in the development of cork-based products.

Pacific Certifications is accredited by ABIS, if you need more support with ISO 2030, please contact us at +91-8595603096 or support@pacificcert.com

Read About : ISO 2028:2015