What is ISO 17712?

ISO 17712:2013 specifies the requirements for mechanical seals used on freight containers. These seals are critical for securing containers during international transport and preventing unauthorized access or tampering. The standard applies to high-security seals, security seals, and indicative seals, each serving different levels of protective assurance.

Developed in collaboration with customs, freight authorities and supply chain operators, ISO 17712 helps to ensure container integrity from origin to destination, playing a key role in supply chain security and compliance with customs and anti-terrorism programs like C-TPAT (U.S.) and AEO (EU).

If you are looking for ISO 17712 certification for container seals, contact us at support@pacificcert.com

Purpose of ISO 17712

The purpose of ISO 17712:2013 is to:

- Establish uniform classification, testing, and strength criteria for mechanical container seals.

- Minimize the risk of seal substitution, manipulation, or breakage during shipment.

- Support border and customs control, providing evidence of potential unauthorized entry.

- Enhance supply chain integrity and trust in international logistics operations.

If your company manufactures or distributes container seals, contact us at support@pacificcert.com

Scope & Applicability

This standard defines mechanical requirements, tamper evidence features, and test procedures for seals used on freight containers in international commerce. It applies only to single-use mechanical seals and excludes reusable locking mechanisms or electronic tracking seals.

Applicability:

ISO 17712 is relevant to:

- Manufacturers of mechanical security seals

- Freight and intermodal logistics companies

- Customs authorities and border security agencies

- Seal testing laboratories and certification bodies

- Importers/exporters and supply chain risk managers

If you are looking to certify seals under ISO 17712, contact us at support@pacificcert.com

Key Definitions

- High-Security Seal (HSS): A seal meeting the highest security level, resistant to physical attacks, and tested according to ISO 17712 and C-TPAT criteria.

- Security Seal: Offers moderate resistance and tamper evidence, but does not meet HSS strength requirements.

- Indicative Seal: Provides minimal protection, used primarily for detection rather than prevention of tampering.

- Tamper Evidence: A seal’s capacity to show visible signs of manipulation or breach.

- Seal Testing: Laboratory process where seals are exposed to axial, shear, impact, and bending forces to assess resistance levels.

If you need assistance understanding seal categories and compliance, contact us at support@pacificcert.com

Clause-wise Structure of ISO 17712

Clause | Title | Overview |

1 | Scope | Defines the application and exclusions of the standard. |

2 | Normative References | Lists other standards essential for application (e.g., ISO 868). |

3 | Terms and Definitions | Provides terminology for seals, testing, tamper evidence, etc. |

4 | Classification of Seals | Categorizes seals into indicative, security, and high-security classes. |

5 | General Requirements | Addresses seal structure, materials, and general design rules. |

6 | Physical Strength Test Requirements | Details mandatory strength tests for each class of seal. |

7 | Tamper Evidence Requirements | Specifies how seals must show visible evidence of forced entry or tampering. |

8 | Marking Requirements | Details required identification marks (e.g., manufacturer ID, unique serial number). |

9 | Test Procedures | Describes laboratory test conditions and parameters. |

If you require audit support for ISO 17712, contact us at support@pacificcert.com

What are the requirements of ISO 17712?

To comply with ISO 17712:2013, manufacturers and users of container seals must:

- Mechanical Strength Classification

The standard defines three categories of mechanical seals, based on their physical strength and intended level of security:

Seal Type | Description |

Indicative Seal | Detects tampering but offers little resistance to forced entry (low strength). |

Security Seal | Offers moderate resistance; requires tools for removal (medium strength). |

High-Security Seal | Designed for high-risk shipments; must meet stringent strength tests (e.g., bolt and cable seals). Certified under C-TPAT. |

Only high-security seals are acceptable under C-TPAT and similar customs security programs.

- Physical Testing Requirements

High-security seals must pass the following physical and mechanical strength tests, verified by an ISO/IEC 17025 accredited laboratory:

- Impact resistance test

- Bending test

- Shear test

- Axial force test

- Tensile test

Each test simulates realistic tampering or forced removal scenarios and sets minimum strength thresholds for each seal category. Other requirements are:

- Produce mechanical seals tested to resist tampering, cutting, impact, and forced entry.

- Ensure seals are marked with unique identification numbers, manufacturer codes, and classification (e.g., “H” for high-security).

- Submit seal samples to an ISO/IEC 17025-accredited testing laboratory for mechanical and tamper evidence testing.

- Maintain traceability records for all seal lots, including design specs, test reports, and production batches.

- Conduct periodic retesting to ensure continued conformity for mass production lots.

- Provide documentation to customs or clients upon request, proving compliance with ISO 17712 requirements.

If you are preparing seals for compliance testing, contact us at support@pacificcert.com.

Documentation Required

- Seal drawings, design specifications, and manufacturing data

- Material composition records and tamper resistance reports

- Unique serial number tracking logs

- Product batch control records

- Laboratory testing reports for each seal type/class

- Marking verification documentation

- Quality management system documentation (if integrated with ISO 9001)

If you need help assembling documentation for ISO 17712 certification, contact us at support@pacificcert.com

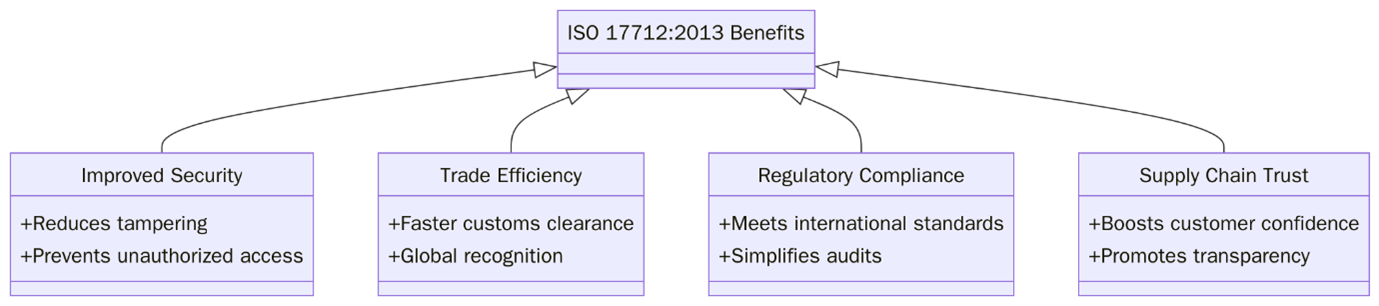

What are the benefits of ISO 17712?

ISO 17712:2013 enhances global cargo security by providing a standardized method for classifying and testing mechanical seals used on freight containers. By ensuring seals are tamper-evident, uniquely identifiable, and resistant to unauthorized access, the standard helps prevent theft, smuggling, and cargo tampering during international transit. Below are the other benefits:

- Supports C-TPAT, AEO, and SAFE Framework requirements for cross-border container shipments.

- Ensures visibility of unauthorized access attempts.

- Reduces risks of pilferage, fraud, and theft during transit.

- Recognized by international customs and transportation security agencies.

- Provides verifiable assurance to importers, freight partners, and insurers.

- Enables seal products to be sold and specified in international container contracts.

- Supports audit trails and inventory validation for logistics operators.

- Establishes competitive advantage in seal manufacturing and export markets.

Recently, demand for ISO 17712-certified high-security seals is rising due to increasing threats to global trade, including container theft, counterfeit goods, and smuggling. Government authorities are tightening import/export regulations, and supply chains are being required to show documented security practices.

Technologies like blockchain traceability, smart seals with GPS or RFID, and biometric locks are emerging alongside traditional seals. However, mechanical seals remain the first line of defense for freight container security, especially where electronic tracking is not feasible.

Logistics operators, third-party freight handlers, and even insurance companies are now factoring ISO 17712 compliance into risk assessments, making certification an essential part of international trade readiness.

If you are manufacturing or sourcing container seals for export markets, contact us at support@pacificcert.com.

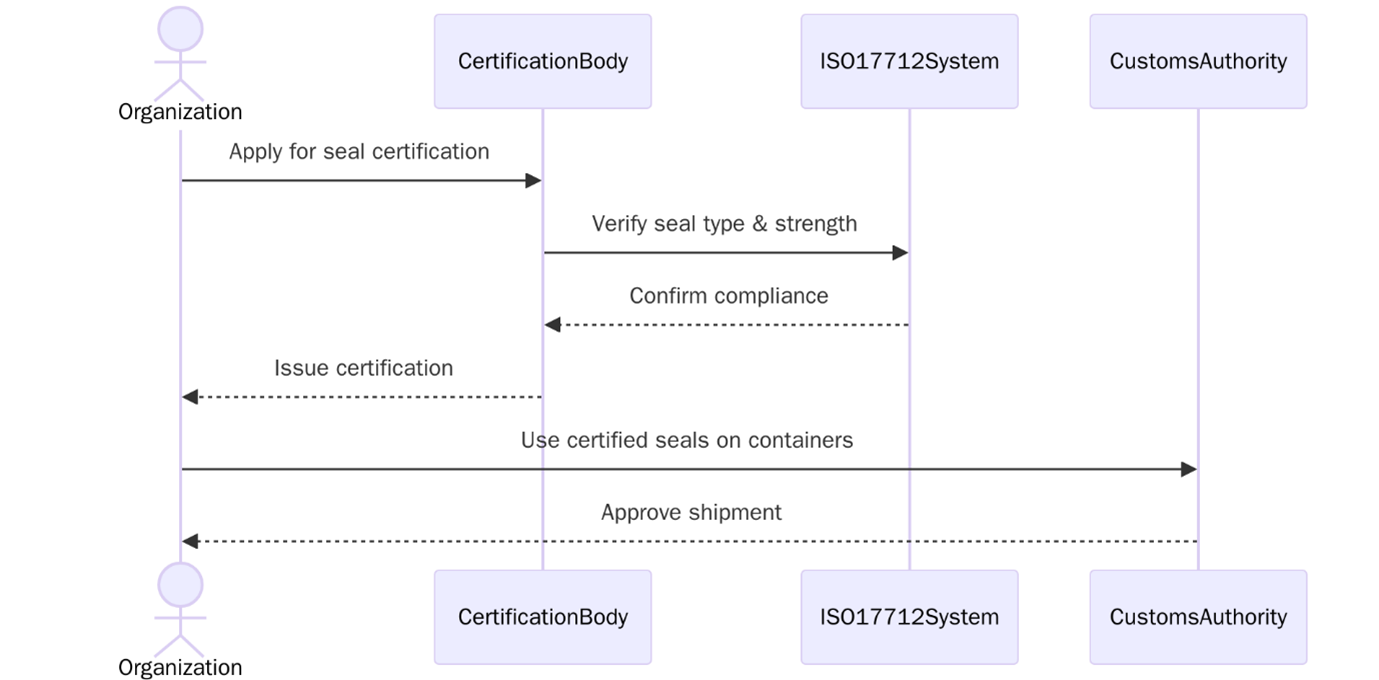

Certification Timeline

Obtaining ISO 17712 certification follows a structured and time-bound process that spans 4 to 6 weeks, depending on the complexity of the product and availability of laboratory testing. Here’s a week-by-week breakdown:

Week-wise Certification Timeline

Week | Stage | Activity Description |

Week 1 | Application & Technical Review | Submission of seal specifications, design drawings, material data, and manufacturer ID. Certification body confirms scope. |

Week 2 | Sample Selection & Lab Coordination | Sample seals are selected for testing and forwarded to an accredited laboratory. Batch traceability is documented. |

Week 3 | Mechanical Testing & Tamper Simulation | Lab performs axial, shear, bending, and impact tests; checks for visible tamper evidence per standard. |

Week 4 | Test Report Issuance | Detailed reports are reviewed by the certification body to confirm conformity. |

Week 5–6 | Certification Decision & Documentation | Certificate of Conformity is issued; seal markings and lot control documentation are finalized. Optionally aligned with C-TPAT or AEO requirements. |

Certification Cost

The cost of ISO 17712 certification is influenced by several factors including:

- Number and variety of seal models being tested

- Accredited laboratory fees for physical and tamper testing

- Manufacturer location and shipping of test samples

- Need for on-site factory audits or inspection (if required by buyers or regulations)

- Re-testing or re-certification costs if seals fail to meet required strength or marking criteria

To get a cost estimate for ISO 17712 testing and certification, contact us at support@pacificcert.com

How Pacific Certifications Can Help?

At Pacific Certifications, accredited by ABIS, we offer specialized certification services for product conformity standards like ISO 17712.

We assist with:

- Technical file and application review

- Coordination with ISO/IEC 17025-accredited laboratories

- Evaluation of mechanical and tamper resistance test results

- Verification of marking, serial control, and manufacturing traceability

- Issuance of Certificates of Conformity for global trade use

- Surveillance for product batches under continued production

If you are looking for ISO 17712 certification, contact us at support@pacificcert.com.

FAQs: ISO 17712

Can one certification cover multiple models?

Each distinct design or product type must be individually tested and certified, even if they are from the same manufacturer.

Is ISO 17712 certification mandatory for all container seals?

Not mandatory globally, but required for compliance with C-TPAT and AEO programs in many countries.

What’s the difference between high-security and indicative seals?

High-security seals undergo rigorous strength and tamper resistance testing and are used for international shipping. Indicative seals are used mainly for domestic or low-risk shipments.

What happens if a seal fails testing?

The product must be redesigned and retested before certification can be issued. Design and material changes must be clearly documented.

Can Pacific Certifications help with both testing and certification?

Yes. We coordinate testing through accredited labs and conduct independent conformity assessments for final certification.

Ready to get ISO 17712 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs