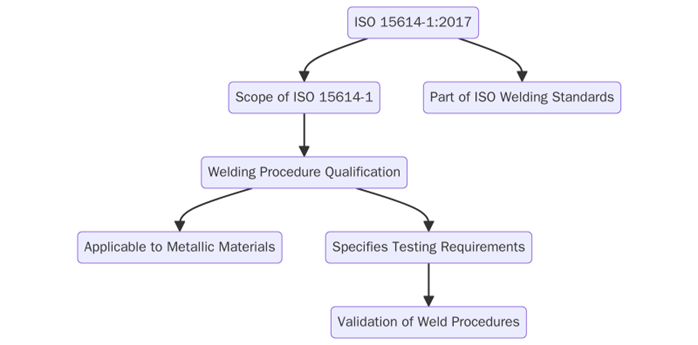

ISO 15614-1:2017 is the primary international standard used for the specification and qualification of welding procedures for metallic materials. It defines how welding procedure tests should be conducted and evaluated to verify that a proposed welding process produces joints with acceptable mechanical and metallurgical properties. This standard is important across industries such as construction, shipbuilding, automotive, aerospace, energy, and heavy manufacturing where metal welding plays a critical role in structural performance.

The standard covers fusion welding of steel, nickel, titanium, aluminum and other metallic materials. By following ISO 15614-1, fabricators and welding service providers can ensure consistent weld quality, meet customer requirements, and align with both contractual and legal obligations in global trade.

To begin your ISO 15614-1 audit or certification process, reach out to us at support@pacificcert.com

Purpose

The main objective of ISO 15614-1 is to validate that a specific welding procedure can consistently produce welds of acceptable quality for the intended application. This is done through a welding procedure qualification record (WPQR) that documents test results, including destructive and non-destructive examination outcomes.

Unlike general welding practices, this standard is performance-based, meaning the success of the qualification depends on the actual test results, not theoretical planning alone. It provides a practical framework for verifying welding procedures in advance, reducing failures, material waste and costly rework.

Scope and Applicability

ISO 15614-1 applies to all organizations that conduct fusion welding of metallic materials. Its application is particularly widespread in industries where welded joints are safety-critical or must meet specific mechanical performance benchmarks.

It is applicable to a range of fusion welding processes including TIG, MIG/MAG, MMA and submerged arc welding (SAW). The standard addresses both manual and automated welding setups and is suitable for new product development, routine production and subcontractor qualification.

This standard is used globally to fulfil requirements under ISO 3834 (Quality in welding) and EN 1090 (for structural steel in Europe) and often accompanies contractual requirements in international projects.

Key Definitions

- Welding Procedure Specification (WPS): A written document describing welding variables for a specific application to ensure repeatability.

- Welding Procedure Qualification Record (WPQR): A record of test results verifying that a welding procedure produces acceptable welds.

- Test Piece: A sample welded under specific parameters and subjected to inspections.

- Parent Metal: The base material being welded, which must meet the scope of ISO 15614-1.

- Fusion Welding: A process that melts base metals to form a joint, typically without pressure.

Clause-wise structure of ISO 15614-1:2017

Clause | Title | Description |

1 | Scope | Defines applicability to metallic fusion welding processes. |

2 | Normative References | Lists referenced standards supporting ISO 15614-1. |

3 | Terms and Definitions | Clarifies terminology used in welding qualification. |

4 | Preliminary Welding Procedure Specification (pWPS) | Initial planning stage of welding variables. |

5 | Welding Procedure Test | Requirements for conducting actual weld tests. |

6 | Test Methods | Destructive and non-destructive testing procedures for weld quality. |

7 | Range of Qualification | Specifies which variations in welding parameters remain valid after testing. |

8 | Re-testing | Guidelines on repeat testing if initial tests fail. |

9 | Validity and Revalidation | Explains how long a WPQR remains valid and how to renew it. |

What are the requirements of ISO 15614-1:2017?

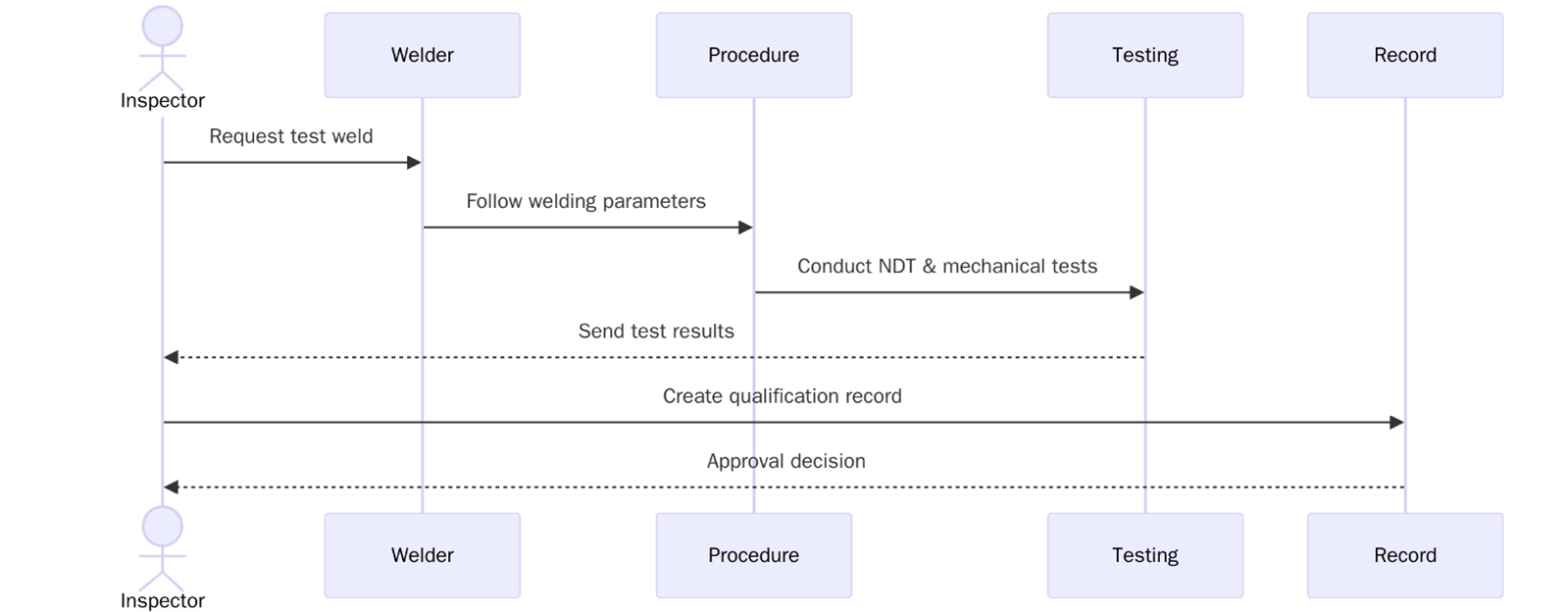

Before applying ISO 15614-1, organizations must clearly define the intended weld application, material type, joint configuration, and welding process. The welding procedure test must then be performed under controlled conditions, documented and evaluated. Below are some of the key requirements:

- Prepare a WPS (Preliminary Welding Procedure Specification) outlining all parameters such as heat input, material, joint type, filler material, and welding technique.

- Perform welding on a representative test piece using actual production conditions.

- Subject the welded test piece to inspections, including Visual inspection, Radiographic or ultrasonic testing, Mechanical testing (tensile, bend, impact) and Metallographic examination (macro, micro, hardness)

- Document the test results in a WPQR report.

- Define the range of qualification such as material thickness, diameter, welding position, and parent metal group.

- Retesting is required if any part of the test fails.

- Update or revalidate the WPQR if significant changes are made to welding parameters or materials.

To begin your ISO 15614-1 audit or certification process, reach out to us at support@pacificcert.com

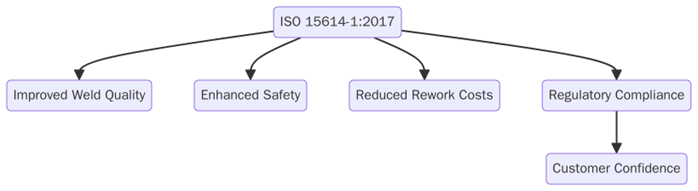

What are the benefits of ISO 15614-1:2017?

The benefits of ISO 15614-1 go beyond weld quality, it supports supplier qualification, international trade, and consistent production output. Below are some of the key benefits:

- Reduced defects and rework through validated welding processes and controls

- Improved credibility with clients and regulators via documented procedure qualification

- Better alignment with ISO 3834 and ISO 9001 quality management systems

- Wider access to contracts requiring standardized welding procedure qualification

- Higher product reliability by eliminating variations in welding quality

- Cost savings due to reduced scrap and process optimization

In recent years, companies have leveraged ISO 15614-1 to meet new environmental and safety regulations linked to welded infrastructure and transport equipment. With automation and advanced welding technologies expanding, this standard remains central to qualifying robotic and hybrid processes, especially in automotive and aerospace sectors.

In the upcoming years, ISO 15614-1 adoption continues to rise due to growing quality expectations in the energy, transportation, and heavy machinery sectors. With governments worldwide investing in public infrastructure, compliance with welding quality standards has become a bidding prerequisite for suppliers.

ISO 15614-1 Audit Checklist

While ISO 15614-1 itself is not certifiable as a standalone, audits under ISO 3834 or ISO 9001 often include welding procedure checks. A sample checklist includes:

- Has a valid WPQR been created for each welded product?

- Are test methods and results properly documented and traceable?

- Is there evidence of personnel qualification (welders and inspectors)?

- Are deviations or changes to welding parameters documented and approved?

- Are PWPS and WPS versions archived and updated?

- Are non-conformities in weld tests addressed with requalification?

Certification Process and Procedure

While ISO 15614-1 is a procedural standard and not directly certifiable, it plays a vital role in qualifying welding procedures under broader quality frameworks such as ISO 3834 and ISO 9001. Here’s how most companies approach implementation:

- Define the WPS: Prepare the planned procedure based on material, process, and design intent.

- Conduct the Welding Test: Perform welds under controlled conditions using qualified welders.

- Testing & Analysis: Use destructive and NDT methods to evaluate weld integrity.

- Record the WPQR: Document all findings and define the scope of the qualified process.

- Internal Review or External Audit: Align with ISO 3834 or contractual third-party inspections.

For support in aligning ISO 15614-1 with certifiable standards, contact us at support@pacificcert.com

Timeline for Implementation

Welding procedure qualification under ISO 15614-1 typically takes 2 to 6 weeks. This includes preparation, performing the test weld, testing the sample, documentation and internal approval. The timeline may extend if re-testing is required or if third-party witness inspections are mandated.

Cost of Implementation

The cost of applying ISO 15614-1 varies depending on the number of procedures being qualified, the types of tests required, and whether destructive testing is outsourced. When integrated into ISO 3834 or ISO 9001 audits, many companies can reduce costs by combining efforts. Key expenses include welder time, materials, testing fees and documentation effort.

How Pacific Certifications Can Help?

At Pacific Certifications, we provide third-party ISO audits that include evaluations of your welding documentation and processes. While ISO 15614-1 is not certifiable independently, we assist with:

- Integration of ISO 15614-1 into ISO 9001 or ISO 3834 audits

- Review of WPQR and WPS documentation

- Preparation for customer or regulatory audits

- Certification support for welding-related standards

To align your welding qualification process with ISO standards, contact us at support@pacificcert.com

Training and Courses

Organizations applying ISO 15614-1 benefit greatly from targeted training programs such as:

- Lead Auditor Training – Focused on welding audits within ISO 9001 and ISO 3834

- Lead Implementer Training – Technical training for preparing WPQR and WPS

- Internal Auditor Training – For QA/QC teams responsible for internal welding compliance checks

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 15614-1 or welding-related training, contact us at support@pacificcert.com

Frequently Asked Questions (FAQs)

Is ISO 15614-1 certifiable?

No, it is a procedural standard used to qualify welding methods, not a certifiable management standard.

Can it be used with ISO 9001 or ISO 3834?

Yes, ISO 15614-1 supports technical requirements in both systems, especially for product and process validation.

Does ISO 15614-1 apply to robotic welding?

Yes, the standard can be applied to automated or robotic welding provided test welds are performed under those conditions.

How long is a WPQR valid?

It remains valid as long as no important variable is changed. Some industries may require periodic revalidation.

Is third-party witnessing mandatory?

Not always, but it may be required by customers, legal contracts, or specific quality schemes.

What new test levels appear in ISO 15614-1:2017?

The 2017 revision introduces two options—Level 1, which mirrors the lighter requirements of ASME Section IX, and Level 2, which keeps the wider test programme from earlier ISO editions. A procedure qualified at Level 2 automatically covers Level 1, but the reverse is not true.

Does ISO 15614-1 demand more examinations than simple tensile and bend tests?

Yes. Alongside those basic checks, the standard calls for visual inspection, volumetric testing such as radiography or ultrasonics, surface crack detection and a macro-section. These extra steps verify internal soundness and fusion quality that tensile tests alone might miss.

How are thickness and diameter ranges qualified under ISO 15614-1?

The joint you weld during the procedure test sets the envelope for future production work. Clause 8 details how plate thickness, pipe wall and outside diameter extend—or do not extend—qualification. For example, a single test on thin plate will not cover heavy-wall pipe unless further coupons are welded.

Can one procedure meet both ISO 15614-1 and ASME IX in a single test?

In many cases, yes. If the coupon is prepared to ISO Level 1 requirements—essentially the ASME scheme—most auditors accept dual stamping. Firms that need global supply clearance often choose Level 2, which automatically satisfies ASME IX while also meeting the stricter ISO scope.

Ready to get ISO 15614-1:2017 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs