What is ISO 13855?

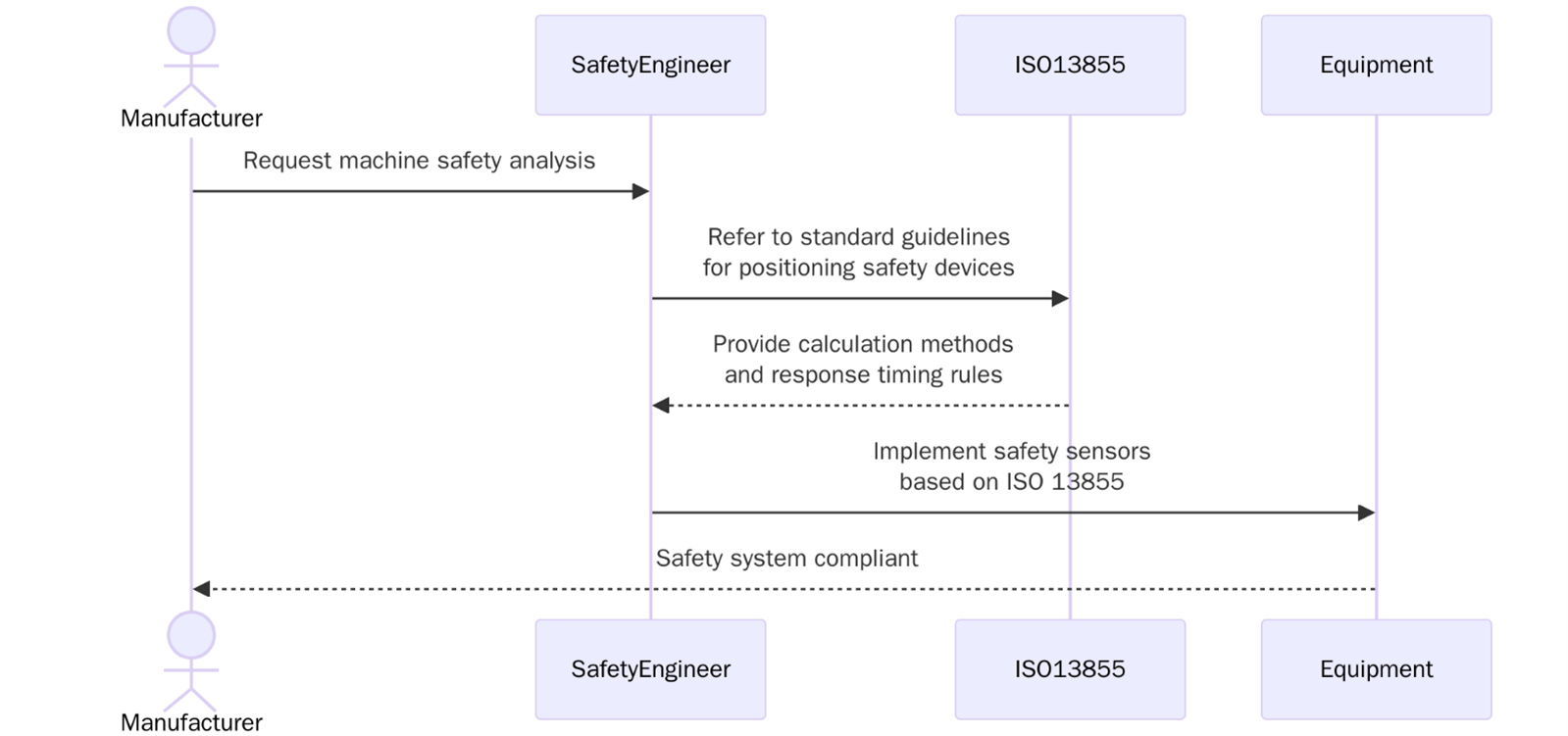

ISO 13855:2024 is an international standard that specifies the positioning of safeguards with respect to the approach of the human body to ensure machinery safety. It outlines the appropriate distances and methods for positioning machine safeguards to prevent injuries caused by contact with moving parts, especially in situations where human interaction with machinery is common. The standard is aimed at reducing the risk of accidents by ensuring that the machine’s safeguards are placed in perfect positions to prevent any part of the human body from coming too close to hazardous areas.

By following ISO 13855:2024, manufacturers and operators can ensure that their machinery operates in compliance with safety requirements, improving the overall protection of workers and reducing the likelihood of accidents in industrial environments.

For more information, contact us at support@pacificcert.com.

Purpose

The purpose of ISO 13855:2024 is to provide a standardized approach to safeguard positioning in machinery design and operation. The standard helps manufacturers identify the correct distances between workers and potentially hazardous machine parts, ensuring that safety measures are effective and that machinery is designed with worker safety in mind.

The guidelines also support reducing the likelihood of workplace injuries by addressing the human body’s interaction with machinery and safeguarding critical machine components.

Scope and Applicability

ISO 13855:2024 is applicable to all types of machinery and machines where the safety of human operators or maintenance personnel is a concern. The standard applies to a broad range of industries, including manufacturing, automotive, food processing, construction, and more. It is intended for use by machinery designers, engineers, and safety professionals who are responsible for ensuring that machines are designed and operated safely.

The standard provides specific guidance on how to position safeguards relative to the reach of the human body, helping businesses comply with both national and international safety regulations.

Key Definitions

- Safeguards: Devices or physical barriers placed around a machine to protect human operators from coming into contact with hazardous moving parts or energy sources.

- Human Reach: The maximum distance that the human body, specifically the arm or hand, can extend towards a machine without any external force.

- Safety Distances: The calculated distances between a machine’s moving parts and the worker, ensuring that the risk of injury is minimized.

- Machinery Safety: A field of safety that focuses on designing and operating machines in a way that ensures the safety of people interacting with them.

- Hazardous Zones: Areas within or around a machine where workers are at risk of injury from moving parts, electrical components, or other dangerous mechanisms.

Clause-wise structure

Clause Number | Title |

| Description |

Clause 1 | Scope | Defines the scope of the standard, specifying the types of machinery covered and the applicability of safeguard positioning. | |

Clause 2 | Normative References | Lists the standards and documents referenced in ISO 13855:2024. | |

Clause 3 | Terms and Definitions | Provides definitions for key terms related to machine safety and safeguard positioning. | |

Clause 4 | General Principles | Outlines the fundamental principles for positioning safeguards based on human body reach and machine operations. | |

Clause 5 | Requirements for Safeguard Positioning | Specifies the requirements for determining the correct placement of safeguards to prevent access to dangerous areas. | |

Clause 6 | Safety Distances and Human Reach | Provides guidelines on how to calculate the correct safety distances based on human reach and machine hazard zones. | |

Clause 7 | Special Considerations | Discusses special considerations, such as different body dimensions and machine types, that might impact the positioning of safeguards. | |

Clause 8 | Monitoring and Testing | Describes how to test and verify the effectiveness of safeguard positioning in ensuring human safety. |

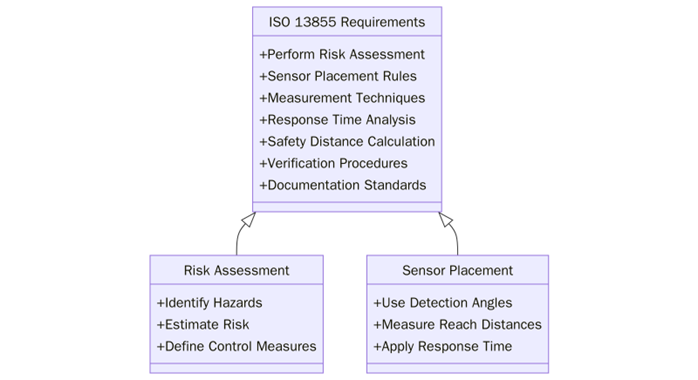

What are the requirements of ISO 13855?

ISO 13855:2024 specifies key requirements for the effective positioning of machine safeguards in relation to the human body. Organizations need to carefully design and position safeguards based on worker reach and proximity to dangerous parts of the machine.

- Safeguards must be positioned at distances that prevent any body part from coming into contact with hazardous machine areas. The standard provides specific guidelines for determining these distances based on human reach and the machine’s operating conditions.

- Safeguards must take into account the maximum reach of workers’ arms, as well as body dimensions, to determine the required safety distance.

- The standard provides guidance on positioning both fixed and adjustable safeguards, ensuring that they prevent accidental contact with hazardous parts during operation or maintenance.

- Safeguards should be positioned in a way that allows operators to safely interact with the machinery without compromising their posture or ease of operation.

- Organizations must test safeguard positioning to ensure that it meets the required safety standards and effectively prevents any accidental contact with moving parts.

For more information, contact us at support@pacificcert.com.

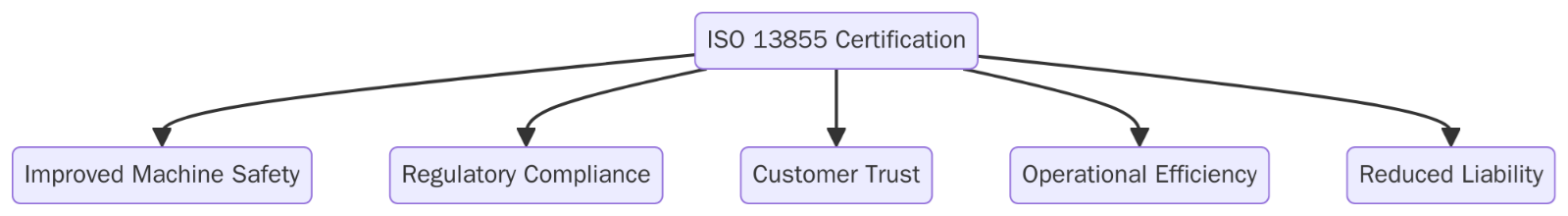

What are the benefits of ISO 13855 Certification?

ISO 13855 certification enhances the safety and operational efficiency of machinery, ensuring that operators and maintenance personnel are protected from hazards. It also demonstrates a commitment to compliance and best practices in workplace safety. Below are the key benefits of obtaining ISO 13855 certification:

- Certification ensures that machinery safeguards are positioned effectively to protect workers from harm.

- Certification helps organizations comply with safety regulations and standards, reducing the risk of non-compliance penalties.

- Proper safeguard positioning minimizes the likelihood of injuries from contact with hazardous moving parts.

- Machines designed with proper safeguards improve efficiency by reducing downtime due to accidents and maintaining regulatory compliance.

As industries continue to prioritize workplace safety, the demand for ISO 13855 certification is expected to grow significantly in the recent years. Increased awareness of workplace hazards and growing regulatory requirements will drive organizations to adopt ISO 13855 as a framework for positioning machine safeguards. Certification will become a key requirement in ensuring safe working environments in high-risk industries such as manufacturing, automotive, and mining.

Certification Process

The certification process for ISO 13855 typically includes the following steps:

- Pre-Certification Assessment: Conducting a gap analysis to identify areas for improvement in safeguard positioning and overall machine safety.

- Documentation Review: Reviewing the organization’s processes, safety protocols, and records to ensure compliance with ISO standards.

- Stage 1 Audit: A preliminary audit to assess the organization’s readiness for certification and identify any potential issues in safeguard positioning.

- Stage 2 Audit: A overreaching on-site audit to evaluate the actual positioning of safeguards and verify compliance with ISO 13855.

- Certification Decision: Certification is awarded once all requirements are met, and the organization demonstrates effective safeguard positioning.

- Ongoing Monitoring: Regular surveillance audits to ensure continued compliance and effectiveness of safeguard positioning.

Timeline for ISO 13855 Certification

The timeline for ISO 13855 certification typically spans several months. The pre-assessment and preparation phase generally takes 1-2 months, during which the organization reviews its current practices and ensures they align with ISO 13855 requirements. The Stage 1 audit lasts about 1 month. The Stage 2 audit, which involves a more overreaching review, takes 1-2 months. Certification issuance occurs within 3-6 months, depending on audit findings and the organization’s readiness for certification.

What is the cost of ISO 13855?

The cost of ISO 13855 certification depends on several factors, including the size of the organization, the complexity of its operations, and the number of machines requiring safeguard assessment. Typical costs include:

Audit Fee is the Fee for the certification body’s audit process. Training costs are the costs for educating staff on ISO 13855 and the necessary processes for compliance. Ongoing maintenance are the costs for regular audits and recertification, typically required every 3 years.

How Pacific Certifications Can Help?

At Pacific Certifications, we provide overreaching auditing and certification services for ISO 13855. Our team will guide you through the entire certification process, ensuring that your machinery safeguards meet the highest standards of safety. Our services include:

- Stage 1 and Stage 2 audits to evaluate safeguard positioning and safety protocols.

- Objective conformity assessments based on ISO 13855.

- Certification issuance upon successful completion of the audit.

- Ongoing surveillance audits to ensure continued compliance.

- Support for multi-site or global operations.

For audits and certification, contact support@pacificcert.com.

ISO 13855 Training and Courses

Various training courses are available to help organizations comply with ISO 13855, including:

- Lead Auditor Training – Equips professionals to conduct external third-party audits.

- Lead Implementer Training – For those responsible for planning and executing ISO 13855 implementation.

- Internal Auditor Training – Preparing internal auditors for certification audits

Pacific Certifications provides accredited training programs. If your organization is looking for ISO training, our team is equipped to help you.

Frequently Asked Questions (FAQs)

How long does it take to get ISO 13855 certification?

The certification process typically takes 3–6 months, depending on your organization’s preparedness and audit outcomes.

Is ISO 13855 certification mandatory for all machinery manufacturers?

While not legally required, ISO 13855 certification is crucial for ensuring machinery safety and meeting industry safety standards.

What are the main benefits of ISO 13855 certification?

Certification ensures that machinery is safe for operators, complies with safety regulations, reduces accident risks, and increases operational efficiency.

Can I apply for ISO 13855 certification without a safety management system in place?

No, a safety management system must be in place before applying for certification to ensure compliance with ISO 13855.

How often do I need to renew ISO 13855 certification?

ISO 13855 certification is valid for three years, after which recertification is required.

Ready to get ISO 13855 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs