What is ISO 10664?

ISO 10664:2014 defines the geometry and dimensions of the hexalobular internal drive used in bolts screws and other externally threaded fasteners. Many know it as the Torx drive. It increases torque transfer and lowers the risk of stripping during tightening. Manufacturers use it in automotive assembly aerospace hardware electronics and industrial equipment. The design fits both manual tools and automated lines where precision and reliability matter.

Companies adopt ISO 10664 to ensure that their fasteners are compatible with standardized tools and meet performance expectations during assembly and maintenance. The standard improves interchangeability between components, supports reliable installations and reduces wear on tooling while helping streamline inventory across product lines.

To schedule an audit or start certification contact: support@pacificcert.com

Purpose

The main purpose of ISO 10664 is to define a consistent internal drive system that offers better engagement between tools and fasteners.

This ensures more stable torque application and minimizes tool slippage. The standard fills a gap for manufacturers who need a reliable fastening method that limits cam-out and supports repetitive tightening in automated or manual assembly.

Scope and Applicability

ISO 10664 applies to the design and specification of internal hexalobular drive recesses used in threaded fasteners. It is relevant to industries that rely on precise mechanical assemblies such as automotive production, machinery fabrication, consumer electronics and defense manufacturing.

For example, a car engine assembly plant can use ISO 10664 fasteners to ensure parts remain intact under vibration while electronics manufacturers prefer these drives for compact assembly and reduced tool wear.

Key Definitions

- Hexalobular: A six-lobed shape designed to improve engagement between driver and recess.

- Drive recess: The internal part of a fastener head where the tool inserts.

- Cam-out: When the driver slips out of the fastener recess, potentially damaging both.

- Torque transmission: The ability to apply rotational force from the tool to the fastener.

- Interchangeability: The ability to use different tools or fasteners without custom modifications.

Clause-wise Structure of ISO 10664

| Clause Number | Title | Description |

| 1 | Scope | Defines the standard’s coverage, focusing on hexalobular recess dimensions |

| 2 | Normative References | Lists referenced documents like ISO fastener standards |

| 3 | Terms and Definitions | Clarifies key technical terms used in the standard |

| 4 | Dimensions and Geometry | Specifies form, size and tolerances of the hexalobular features |

| 5 | Designation of Drive Sizes | Lists standard drive sizes (e.g., T10, T15, etc.) and their applications |

| 6 | Inspection Methods | Outlines how to measure and verify the internal recess |

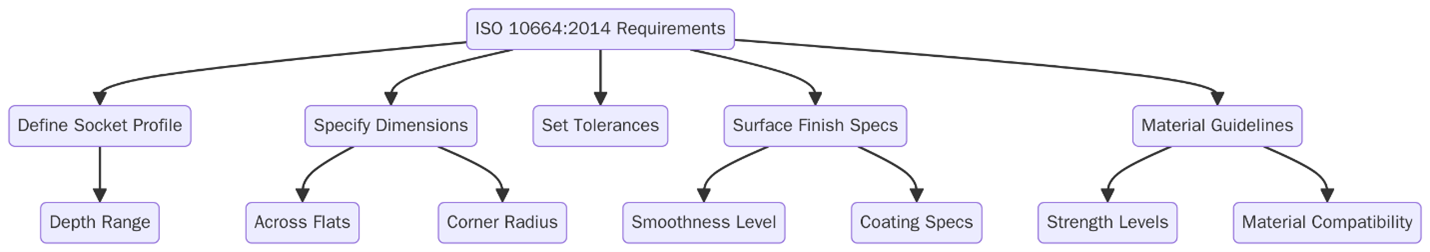

What are the requirements of ISO 10664?

To meet ISO 10664, organizations must follow specific design and inspection steps. These requirements ensure repeatable product quality and drive compatibility. The following are the key requirements that companies need to address when applying ISO 10664 in their operations:

- Identify all product types that require internal hexalobular driving features during the design stage.

- Select drive sizes according to the specified T-size range and ensure they match mechanical performance needs.

- Use correct geometric dimensions and tolerances as per Clause 4 of the standard.

- Validate production tools to create accurate recess profiles on each fastener type.

- Establish inspection routines using gauges or digital measuring tools to verify each batch.

- Maintain records of design drawings and inspection results for audit purposes.

- Train production staff and quality inspectors on proper tool usage and failure detection.

- Link this standard with existing ISO 9001 or API Q1 quality systems for integrated audits.

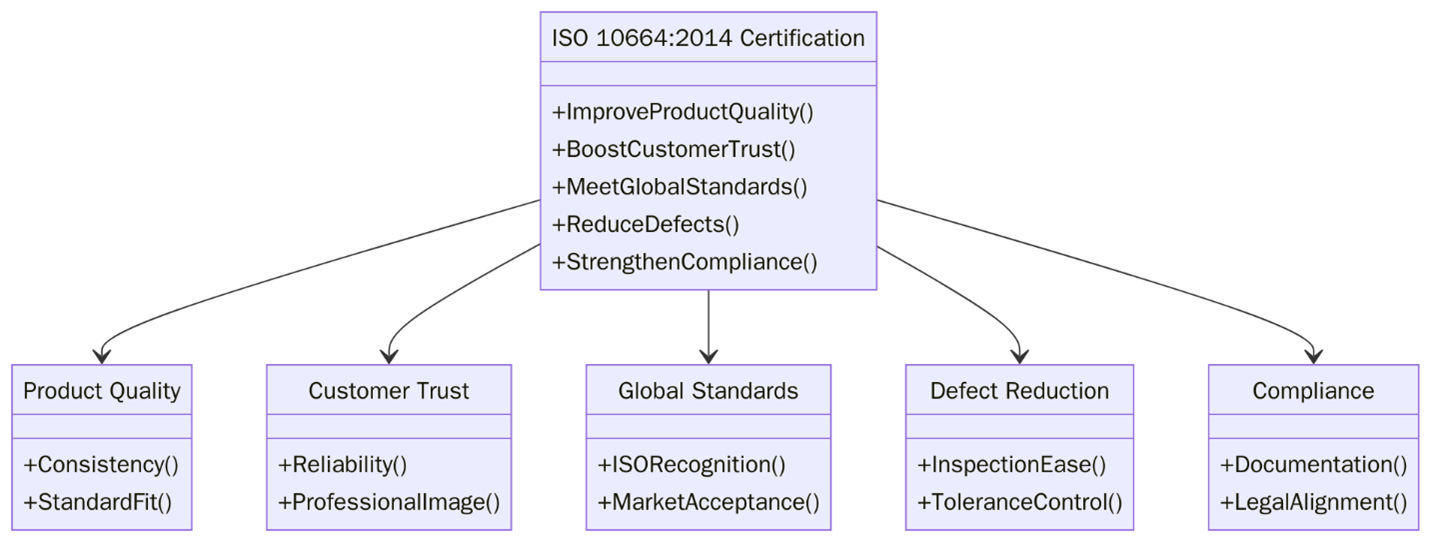

What are the benefits of ISO 10664 Certification?

The Certification to ISO 10664 offers companies a structured way to deliver fasteners that perform reliably during use. It also improves customer satisfaction and manufacturing precision. Below are the main benefits companies can expect after implementing and certifying to ISO 10664:

- Improved torque control across production batches ensures tools grip securely with reduced cam-out during assembly.

- Longer tool and fastener life lowers replacement costs and avoids sudden stoppage during operations.

- Better compatibility across supply chains allows subcontractors and OEMs to use uniform parts.

- Stronger grip in compact spaces makes it ideal for electronics and automotive parts where accuracy matters.

- Increased assembly speed when used with power tools reduces cycle times in production.

- Reduced risk of product failure due to consistent dimensioning and proper tool matching.

- Global acceptance in multiple industries makes it easier to export or scale production.

- Recent industry trends show a steady shift toward internal drives like Torx in place of Phillips to improve durability and quality.

Market Trends

The demand for hexalobular internal drive systems continues to grow across key manufacturing sectors. Companies are moving away from traditional drive types in favor of ISO 10664-based fasteners due to their better torque transfer, reduced cam-out and longer tool life. New variants like Torx Plus and TTAP are being adopted for tighter fit and faster assembly. Many factories now use digital torque tools paired with inspection software to monitor tightening in real time. As precision and efficiency take priority ISO 10664 remains a reliable standard for automotive, aerospace and electronics production worldwide.

Eligibility Criteria for ISO 10664

Any organization involved in designing or manufacturing threaded fasteners with internal drive features can seek ISO 10664:2014 certification. Companies with existing ISO 9001 or API Q1 systems will find the transition easier, especially if they already maintain product drawings, inspection logs and dimensional test records. Whether you manufacture automotive bolts or electronics screws, ISO 10664 applies if you use hexalobular drives.

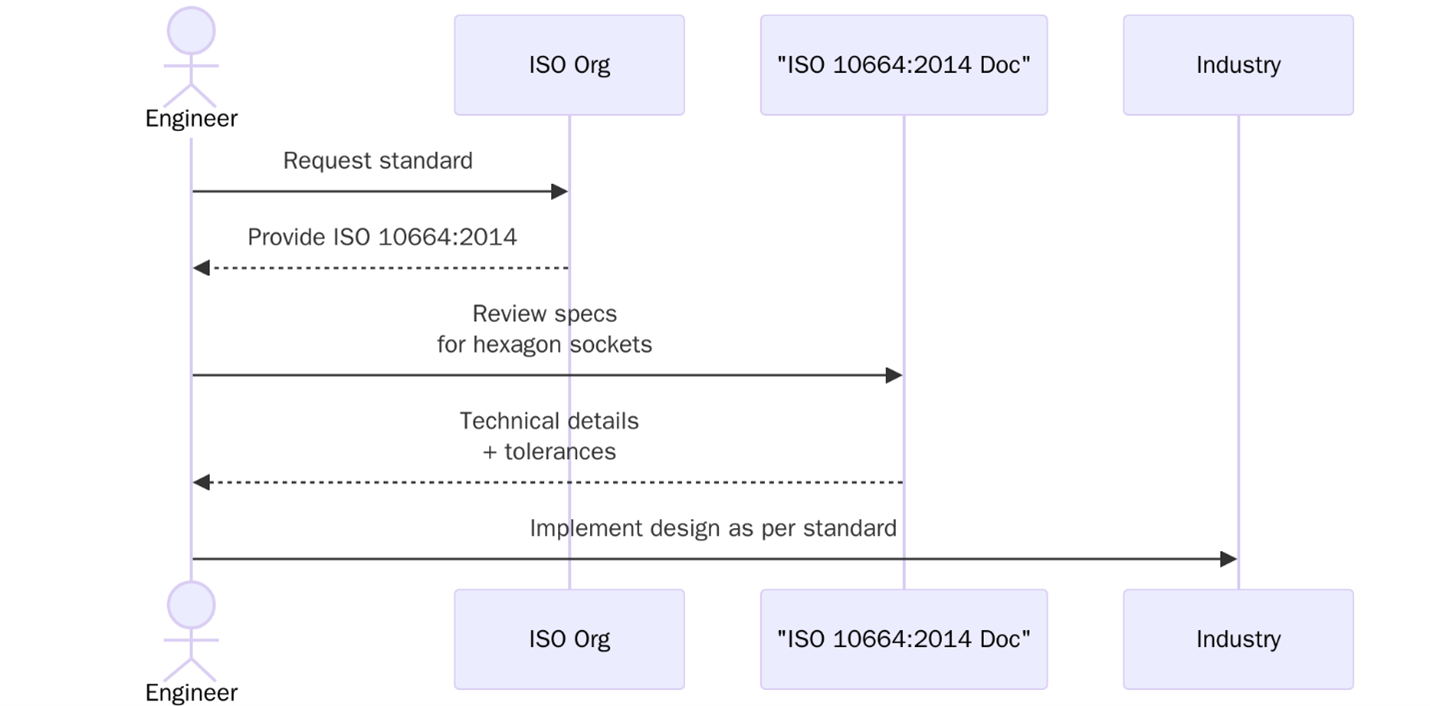

ISO 10664 Certification Process

Review

Initial evaluation of your current product designs, tooling capabilities and quality documentation.

Preparation

Align production processes and inspection routines to ISO 10664 requirements. Training and documentation updates occur in this stage.

Stage 1 Audit

The audit team checks readiness, existing quality systems, calibration of measurement tools and availability of technical drawings.

Stage 2 Audit

In-depth verification of how the standard is applied. Sample inspections, process walkthroughs and conformity tests are conducted.

Certification Decision

Pacific Certifications reviews audit outcomes and issues certification if conformity is met.

Annual Surveillance

Yearly follow-ups ensure your systems continue to meet the standard and that measurement practices remain valid.

Timeline for ISO 10664 Certification

The Certification typically takes six to ten weeks, depending on your organization’s readiness. Companies with documented design processes and gauge-based inspections may complete audits faster. If new tooling validation or operator training is required, the timeline may extend slightly. Multi-site operations might also require phased audits.

What is the cost of ISO 10664?

The Costs vary depending on the number of fastener types covered, the scope of the production line, and whether ISO 10664 is included in a broader audit like ISO 9001 or API Q1. Organizations with well-documented processes and internal inspections in place may reduce audit scope and cost. Custom product ranges or advanced measurement systems may increase total effort.

How can Pacific Certifications Help?

Pacific Certifications supports manufacturers and fabricators through ISO 10664 certification audit and training. Our team focuses on practical evaluations and aligns audits with real welding shop practices.

- Audit welding operations in construction, energy, shipbuilding, and machinery to ISO 3834 quality requirements.

- Expect practical reviews of WPS, PQR, welder qualifications, inspection reports, and records.

- Combine scopes with ISO 9001 or API Q1 where welding sits inside a broader quality system.

- ABIS-accredited certification body—independent audits that align with international expectations.

- Get value-based assessments only. No consulting or document writing. Certification and surveillance are our focus.

- Benefit from code fluency across ASME IX, EN, and AWS during technical review.

- Whether new or renewing, we build flexible audit plans around your welding scope.

Training and Courses

Lead Auditor Training

Covers how to plan, conduct and report audits for ISO 10664 in manufacturing environments.

Lead Implementer Training

Focuses on implementing ISO 10664, from tooling selection to inspection and documentation control.

Internal Auditor Training

Designed for quality staff and production leads to conduct self-reviews and prepare for certification.

FAQs

Is ISO 10664 only used in automotive industries?

No, it is also widely used in electronics, industrial machinery, aerospace and consumer appliances.

Can ISO 10664 be certified along with ISO 9001?

Yes, it is often audited alongside ISO 9001 or API Q1 for production systems.

Do we need custom tools for inspection?

Standard gauges and precision tools can be used if they match dimensional criteria in ISO 10664.

How long is certification valid?

Three years, with annual surveillance audits to confirm continued conformity.

Is testing required for all fastener types?

Yes, representative samples from each product type must be tested during certification.

What company size is ideal for ISO 10664?

It suits all sizes, from small fastener producers to high-volume industrial manufacturers.

Pacific Certifications provides accredited training programs. Contact support@pacificcert.com to schedule your training.

Ready to get ISO 10664 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs