ISO 10218-1:2025: Certification Process, Fees, Eligibility, and How Pacific Certifications Can Help

ISO 10218-1:2025 specifies safety requirements for the design, manufacturing, and integration of industrial robots. It outlines comprehensive safety protocols intended to ensure safe operation during all phases of a robot’s lifecycle, from installation and operation to maintenance and decommissioning. This updated version reflects the latest technological advancements in robotics, addressing collaborative robot systems (cobots), enhanced risk assessments, and more robust protective measures.

Ensuring compliance with ISO 10218-1 is crucial for manufacturers aiming to meet global safety standards and regulatory requirements.

Understanding ISO 10218 Series

The ISO 10218 family includes two critical parts:

- ISO 10218-1:2025: Safety requirements for industrial robots, focusing on the robot itself.

- ISO 10218-2:2011: Safety requirements for robot systems and integration, focusing on the entire robotic system within its environment.

Both parts are interdependent and ensure that not only the robot hardware but also the way it interacts with humans and other machinery, meets comprehensive safety norms. Contact support@pacificcert.com for assistance!

Certification Process and Procedure

Initial Assessment and Risk Analysis:

- Comprehensive hazard identification and risk analysis based on ISO 12100 principles.

- Determine required protective measures for identified risks.

Design and System Planning:

- Design robots with inherent safety, incorporating fail-safe mechanisms, emergency stops, and redundancy.

- Integrate protective measures like guarding, interlocks, and collaborative workspace controls.

Functional Safety Validation:

- Perform functional safety analysis per ISO 13849-1 and/or IEC 62061 to ensure control systems meet necessary safety integrity levels.

Prototype Testing:

- Execute extensive physical and software testing to verify compliance with mechanical, electrical, and control system safety requirements.

Documentation Compilation:

- Develop detailed technical files, risk assessments, test reports, control diagrams, and user manuals.

Internal Audit and Management Review:

- Conduct internal audits of design and manufacturing processes.

- Hold management reviews to ensure resource allocation and process effectiveness.

Certification Audit:

- Pacific Certifications conducts an external audit covering documentation, design verification, and functional safety tests.

Certification Issuance:

- After successful audit and compliance validation, ISO 10218-1:2025 certification is awarded.

Documents Required for ISO 10218-1:2025 Certification

- Detailed Risk Assessment and Hazard Analysis Reports

- Design and Technical Specifications

- Functional Safety Validation Reports (ISO 13849-1/IEC 62061 compliance)

- Mechanical and Electrical Test Reports

- Safety Circuit Diagrams and Schematics

- User Manuals, Installation Instructions, and Maintenance Guidelines

- Internal Audit Reports and Corrective Action Records

- Management Review Documentation

For document guidance, contact support@pacificcert.com!

Eligibility Criteria

ISO 10218-1 certification applies to:

- Manufacturers of industrial robots.

- Designers and developers of collaborative robots (cobots).

- Integrators of robotic systems.

- Organizations supplying robots used in manufacturing, healthcare, logistics, automotive, aerospace, and more.

ISO 10218-1:2025 Certification Cost

Certification fees vary depending on the complexity of the robot and the extent of system integration. Request a customized quotation at support@pacificcert.com.

Certification Duration

The certification timeline includes:

- Initial Risk Analysis and Design Assessment: 3-5 months

- Prototype Validation and Testing: 2-4 months

- Certification Audit and Approval: 1-2 months

Total certification process duration: 7-12 months.

Requirements of ISO 10218-1:2025 Certification

Achieving compliance with ISO 10218-1 requires manufacturers to:

- Conduct Hazard Identification and Risk Reduction: Identify mechanical, electrical, control system, and software-related risks and implement appropriate mitigation strategies.

- Implement Inherent Safety by Design: Use intrinsically safe designs wherever possible, such as smooth surfaces, no pinch points, and low energy actuators.

- Apply Protective Measures: Design and integrate guards, barriers, interlocks, and safe operational speeds into robot designs.

- Ensure Emergency Stop Functionality: Emergency stops must be fail-safe, easily accessible, and operable under any fault condition.

- Provide Clear User Information: Accurate, comprehensive user manuals, maintenance procedures, and warning labels must accompany every device.

- Perform Verification and Validation: Systematic validation that the robot performs safely under foreseeable misuse conditions must be carried out.

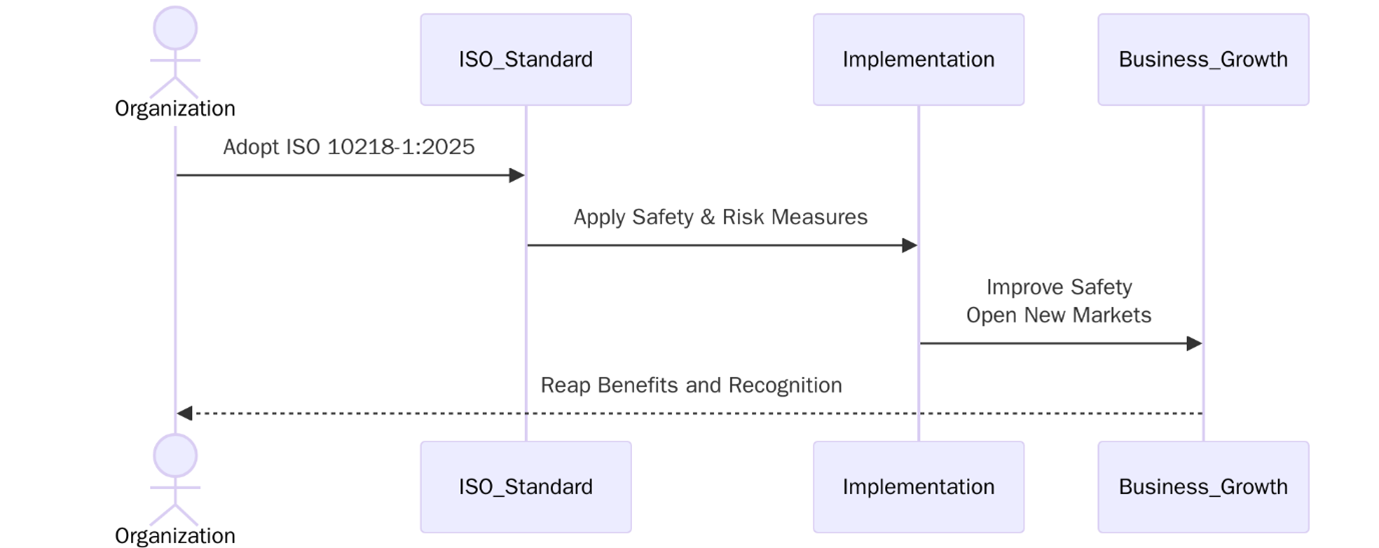

Benefits of ISO 10218-1:2025 Certification

- Operator Safety: Reduces the likelihood of accidents involving robotic systems.

- Compliance: Supports CE marking under the EU Machinery Regulation and eases global regulatory approvals.

- Market Access: Demonstrates a commitment to safety, opening doors to new international markets.

- Marketing Advantage: Certified products stand out for their focus on user safety and innovation.

- Reduced Legal Risks: Lower exposure to liability claims arising from safety incidents.

- Customer Confidence: Clients and end-users trust certified products, strengthening brand reputation.

The robotics industry is witnessing exponential growth fueled by automation across manufacturing, healthcare, and service sectors. With collaborative robots (cobots) becoming increasingly common, the importance of stringent safety compliance has grown manifold. ISO 10218-1 serves as a foundational certification to address this evolving demand, positioning certified manufacturers ahead of the competition.

Stay ahead in the robotics industry by connecting with support@pacificcert.com!

How Pacific Certifications Can Help?

Pacific Certifications provides complete support for ISO 10218-1 certification:

- Trained in international safety standards and robotic technologies.

- From gap analysis to final audit and certificate issuance.

- Certifications recognized internationally, enhancing global market credibility.

- Post-certification surveillance and recertification assistance.

Start your ISO 10218-1 certification journey today by contacting support@pacificcert.com!

Frequently Asked Questions (FAQs)

What is ISO 10218-1:2025?

It’s the international safety standard for industrial robots, setting requirements for inherently safe design, risk-reduction measures, and information for use. The document treats the robot as “partly completed machinery” before it’s integrated into a full system.

Is ISO 10218-1 certification mandatory?

It is not mandatory by law but is crucial for achieving CE marking, regulatory approvals, and ensuring operator safety.

Can ISO 10218-1 certification be integrated with ISO 13849-1?

Yes, IEC/ISO 13849-1 and IEC 62061 can be integrated into the functional safety validation under ISO 10218-1.

What types of robots fall under ISO 10218-1?

Industrial robots used in manufacturing, assembly, material handling, welding, painting, and more.

What happens if a robot system fails compliance testing?

Design modifications, re-validation, and re-testing are required before certification can be granted.

How often should certified systems be re-evaluated?

The major upgrades, safety incidents, or regulatory changes would trigger a re-evaluation. Surveillance audits are usually annual.

What changed in the 2025 edition compared with 2011?

The third edition adds design and mode requirements, clarifies functional-safety expectations, introduces Class I and Class II for functional-safety needs, defines a test method to determine maximum force per manipulator for Class I, adds cybersecurity requirements where safety is affected, and incorporates collaborative-application content that used to live in ISO/TS 15066.

Who is ISO 10218-1 primarily for?

Robot manufacturers are the main audience for Part 1. Integrators and user facilities rely more on Part 2 for system integration and safeguarding, though both parts are relevant across the supply chain.

What doesn’t ISO 10218-1 apply to?

It excludes service robots, consumer products, medical and healthcare robots, military and law-enforcement uses, airborne/space robots, and situations where the public can access the robot. It also isn’t applicable to robots manufactured before its publication date.

Ready to get ISO 10218-1 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –