ISO Certifications for Natural Rubber Product Manufacturing Businesses, Requirements and Benefits

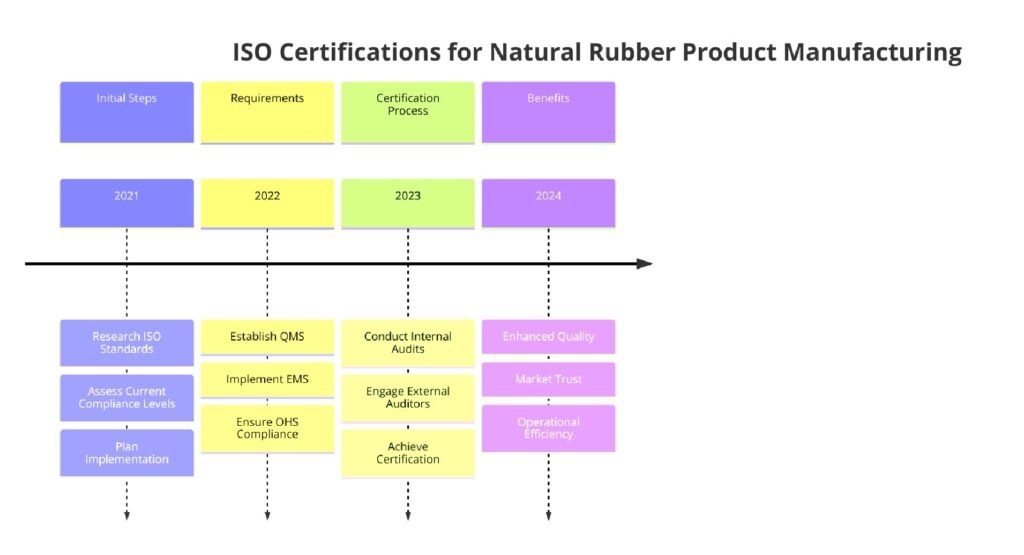

The global natural rubber industry is witnessing dynamic growth and change, driven by evolving market demands, stringent regulatory requirements, and the need for sustainable practices. In this context, obtaining ISO certifications for natural rubber product manufacturing has become a cornerstone for ensuring quality, safety, and environmental responsibility.

ISO standards provide a framework for ensuring the quality and safety of products while emphasizing sustainable and ethical practices. In the natural rubber manufacturing sector, these standards ensure that rubber products meet international benchmarks, thereby enhancing their marketability and compliance with global trade regulations. The natural rubber industry relies on high-performance materials for applications such as automotive, healthcare and consumer goods.

If you’re seeking ISO certification for your natural rubber product manufacturing business, our experts at Pacific Certifications are here to assist. Contact us today at support@pacificcert.com or call +91-8595603096 for professional guidance and certification services.

Applicable ISO Standards for Natural Rubber Product Manufacturing

Numerous ISO standards are directly or indirectly applicable to natural rubber manufacturing. These standards cover various aspects of production. Below are some of the key ISO certifications for natural rubber product manufacturers:

ISO 9001: Quality Management System (QMS): ISO 9001 focuses on quality management and continual improvement. For natural rubber product manufacturers, this standard ensures that processes are optimized for producing consistent, high-quality products.

ISO 14001: Environmental Management System (EMS): This standard is essential for organizations aiming to reduce their environmental impact. Natural rubber production often involves energy-intensive processes, and ISO 14001 ensures compliance with sustainable practices.

ISO 45001: Occupational Health and Safety (OHS): Worker safety is paramount in manufacturing. ISO 45001 provides a framework to mitigate risks, prevent workplace accidents, and foster a safe working environment.

ISO 50001: Energy Management System: Energy consumption is a significant concern in rubber manufacturing. ISO 50001 helps companies manage energy efficiently, thereby reducing costs and carbon footprints.

ISO 14067: Greenhouse Gas Emissions and Carbon Footprinting: This standard enables manufacturers to calculate and minimize the carbon footprint of their natural rubber products, aligning with the industry’s push toward net-zero emissions.

ISO/TS 16949: Automotive Sector-Specific QMS: For manufacturers supplying natural rubber components to the automotive industry, ISO/TS 16949 combines ISO 9001 with sector-specific requirements.

ISO 22301: Business Continuity Management: To mitigate risks related to supply chain disruptions or natural disasters, ISO 22301 ensures that manufacturers have robust contingency plans.

ISO 26000: Social Responsibility: This guidance document promotes ethical practices in manufacturing, ensuring fair labor practices, community engagement, and environmental stewardship.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing robust auditing and certification services to help manufacturers achieve compliance with the above-mentioned ISO standards. With years of expertise, we guide natural rubber manufacturers through the certification process, ensuring smooth audits and timely issuance of certificates.

Our team ensures impartiality and precision in auditing, enabling organizations to meet international benchmarks without compromising their operational integrity. When you choose Pacific Certifications, you gain a trusted partner for achieving global recognition through ISO certifications.

Achieving ISO certification for natural rubber manufacturing has never been easier. Contact Pacific Certifications at support@pacificcert.com or call us directly at +91-8595603096 for seamless certification support.

Requirements of ISO Certifications for Natural Rubber Product Manufacturing

Achieving compliance with ISO standards requires manufacturers to adhere to specific requirements that focus on quality, safety, sustainability, and operational excellence. Below is a breakdown of the requirements for each applicable standard in natural rubber product manufacturing:

ISO 9001: Quality Management System (QMS) Requirements

- Customer Focus: Prioritize customer satisfaction by understanding their needs and expectations.

- Leadership Commitment: Establish a clear vision, assign responsibilities, and ensure top management’s active involvement in the QMS.

- Process Approach: Map and manage interconnected processes to achieve consistent quality.

- Risk-Based Thinking: Identify and address risks and opportunities that may impact quality.

- Documented Information: Maintain detailed records of processes, procedures, and outcomes to ensure traceability and accountability.

- Performance Evaluation: Conduct regular audits and reviews to measure performance and drive continual improvement.

ISO 14001: Environmental Management System (EMS) Requirements

- Environmental Policy: Develop and communicate a policy that outlines environmental commitments.

- Identification of Environmental Aspects: Assess the environmental impact of raw material sourcing, production, and waste management.

- Legal Compliance: Ensure operations comply with applicable environmental laws and regulations.

- Resource Management: Optimize the use of energy, water, and raw materials to reduce waste.

- Continuous Improvement: Regularly monitor environmental performance and implement corrective actions.

ISO 45001: Occupational Health and Safety Management System (OHSMS) Requirements

- Hazard Identification: Proactively identify workplace hazards and assess associated risks.

- Worker Participation: Involve employees in developing and implementing safety measures.

- Health and Safety Objectives: Set measurable goals for improving workplace safety and reducing accidents.

- Emergency Preparedness: Develop plans to handle emergencies like chemical spills or machinery failures.

- Compliance Obligations: Adhere to local and international safety regulations.

ISO 50001: Energy Management System (EnMS) Requirements

- Energy Policy: Define and document an energy management policy with specific objectives.

- Energy Baseline: Establish a baseline for energy consumption to identify areas for improvement.

- Energy Performance Indicators (EnPIs): Monitor and measure energy performance regularly.

- Operational Controls: Implement energy-efficient practices in manufacturing processes.

- Employee Awareness: Train employees on energy-saving practices and technologies.

ISO 14067: Carbon Footprint of Products Requirements

- Life Cycle Assessment (LCA): Evaluate GHG emissions across the entire lifecycle of natural rubber products, from sourcing to disposal.

- Data Transparency: Maintain accurate records of emissions data.

- Reduction Targets: Develop strategies to reduce the carbon footprint through cleaner technologies and renewable energy.

Need ISO certification for your natural rubber product manufacturing operations? Our team at Pacific Certifications is just a call or email away! Reach us at support@pacificcert.com or dial +91-8595603096.

Benefits of ISO Certifications for Natural Rubber Product Manufacturing

Adopting ISO certifications yields a multitude of benefits, making them a worthwhile investment for manufacturers.

Quality and Consistency: ISO standards enable manufacturers to deliver products that consistently meet or exceed customer expectations.

Market Access: Certification opens doors to international markets, as buyers often prioritize ISO-compliant suppliers.

Regulatory Compliance: Meeting ISO standards ensures adherence to local and international regulations, minimizing the risk of penalties.

Sustainability Goals: Standards like ISO 14001 and ISO 50001 help manufacturers achieve their environmental and energy efficiency objectives.

Reputation and Trust: ISO-certified companies are perceived as more reliable and trustworthy, enhancing brand reputation.

Cost Savings: Improved processes, reduced waste, and better resource management result in significant cost reductions over time.

The natural rubber industry in 2024 is poised for transformation, driven by technological innovations and increased sustainability efforts. According to market research, the global natural rubber market is expected to grow significantly, with a strong focus on eco-friendly production practices. ISO standards are playing a pivotal role in this transition, as manufacturers seek to align their processes with the growing demand for green products, moreover, supply chain transparency and carbon footprint reduction have become key competitive differentiators in the industry.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Natural Rubber Product Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Natural Rubber Product Manufacturing

What are ISO certifications for natural rubber product manufacturing?

ISO certifications are globally recognized standards that ensure the quality, safety, and sustainability of natural rubber products.

How can ISO 9001 benefit rubber manufacturers?

ISO 9001 enhances quality management practices, ensuring consistent product quality and increased customer satisfaction.

Which ISO standard focuses on environmental sustainability?

ISO 14001 is the key standard for environmental management, helping organizations minimize their ecological impact.

Why choose Pacific Certifications for ISO audits?

Pacific Certifications provides expert auditing and certification services, ensuring a smooth and hassle-free certification process.

Are ISO certifications mandatory for natural rubber manufacturers?

While not mandatory, ISO certifications are highly beneficial for market competitiveness, regulatory compliance, and operational efficiency.

How long does the certification process take?

The timeline depends on the organization’s readiness and the complexity of the required audits. Typically, the process can take a few weeks to several months.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs