What is EN 403:2004?

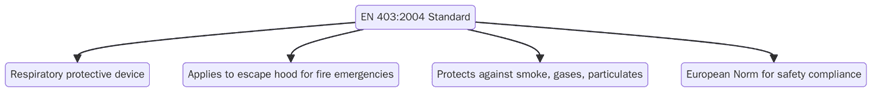

EN 403:2004 establishes requirements for respiratory protective devices (RPDs) intended for self-rescue in hazardous atmospheres. These devices are crucial for workers exposed to sudden toxic gas releases, smoke or oxygen-deficient environments in industries such as mining, chemical processing, firefighting, and confined space operations.

The standard ensures that self-rescue equipment performs reliably in emergencies, protecting workers during evacuation or escape. Compliance with EN 403 provides organizations and employees with confidence that the devices are tested and verified for real-world emergency scenarios.

For guidance on implementing EN 403-compliant self-rescue devices, contact support@pacificcert.com.

What is the Purpose of EN 403:2004?

The purpose of EN 403 is to establish the safety, performance, and usability requirements for respiratory protective devices designed for self-rescue in hazardous environments. These devices are critical for ensuring that workers can safely evacuate from areas with toxic gases, smoke or oxygen-deficient atmospheres, particularly in industries such as mining, chemical processing, confined spaces and emergency response operations. By setting minimum standards for design, functionality, and operational reliability, EN 403 helps organizations protect the health and safety of personnel during emergency situations. The standard also ensures that devices are intuitive to use under stress, maintain protection for the required duration and perform reliably under varying environmental conditions. Compliance with EN 403 contributes to reducing workplace accidents, enhancing emergency preparedness and fostering confidence among employees and regulators alike.

Scope and Applicability

EN 403 applies to all respiratory protective devices intended for self-rescue in environments where immediate withdrawal is required due to the presence of hazardous gases, smoke or insufficient oxygen. The standard is relevant for manufacturers, suppliers, and organizations that provide or use self-rescue devices across multiple industries, including mining, chemical manufacturing, oil and gas, firefighting and confined space operations. It covers both portable and wearable devices designed to provide temporary protection during escape, and establishes uniform criteria for performance, testing, marking and user instructions.

EN 403 is applicable to new devices as well as modifications or updates to existing equipment, ensuring that safety and usability requirements are consistently met. It also serves as a reference for regulatory authorities, safety auditors, and certification bodies to evaluate compliance and ensure that devices meet recognized international safety standards.

Key Definitions

- Self-Rescue Device: A respiratory protective device designed for emergency escape or evacuation.

- Protective Duration: The minimum time the device must provide smooth respiratory protection.

- Toxic Atmosphere: An environment containing gases, vapors, or particles that may cause harm if inhaled.

- Escape Device: Equipment specifically designed to allow safe evacuation from a hazardous area.

- Operational Temperature Range: The range of temperatures within which the device must function smoothly.

Clause-wise Structure

| Clause | Description |

| Scope | Defines the boundaries, objectives, and intended application of self-rescue respiratory devices. |

| Normative References | Lists essential referenced standards and documents required for compliance. |

| Terms and Definitions | Provides standard definitions to ensure consistent understanding. |

| Requirements | Outlines performance, design, construction, operational, and ergonomic requirements. |

| Testing | Details dynamic and static tests including toxic gas resistance, duration, and functional reliability. |

| Marking | Specifies information to be marked on the device, including manufacturer, model, serial number, and protection duration. |

| User Instructions | Provides guidelines for proper use, maintenance, storage, and inspection of devices. |

| Environmental Performance | Covers functionality under temperature, humidity, and other environmental conditions. |

| Documentation | Specifies necessary technical documentation and test reports. |

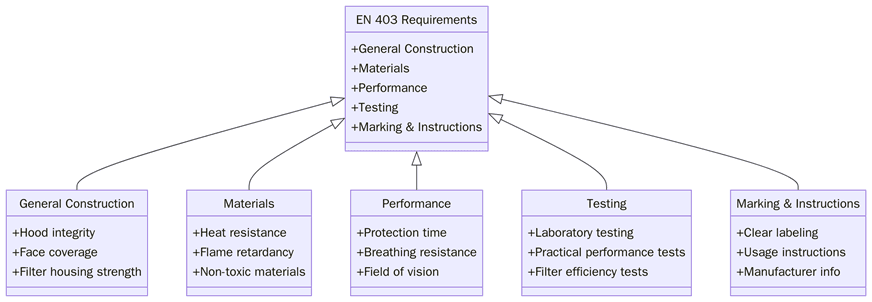

What are the requirements of EN 403?

Before listing the requirements, it is important to understand that self-rescue respiratory devices must function reliably under emergency conditions while being easy to use for workers under stress. Compliance requires rigorous testing and adherence to design standards, ensuring protection from toxic atmospheres during evacuation. Below are some of the key requirements:

- The device must provide a minimum duration of respiratory protection, typically 10–15 minutes depending on the standard and environment.

- The device must be easy to don quickly, without prior adjustments or complex instructions.

- It must provide adequate filtration or oxygen supply to protect against toxic gases, smoke, and oxygen-deficient atmospheres.

- Materials must withstand high temperatures, humidity, and corrosive environments while maintaining performance.

- Devices must be ergonomically designed to allow unrestricted movement during escape.

- The device must pass functional tests simulating real-world emergency conditions.

- Clear marking must include manufacturer details, model, serial number, expiration date, and protective duration.

- overreaching instructions must be provided for use, inspection, storage, and maintenance.

- Devices must maintain performance across temperature ranges expected in the workplace.

- Reusable devices must be capable of repeated inspections and maintenance without degradation.

For guidance on implementing EN 403, contact support@pacificcert.com.

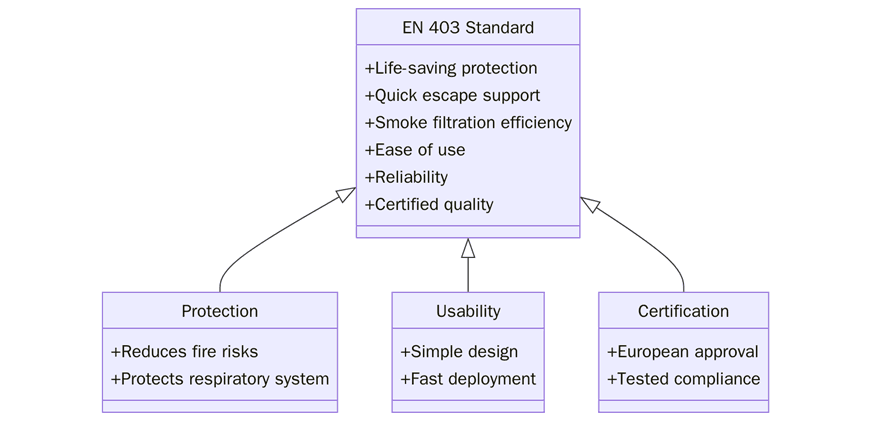

What are the benefits of EN 403?

EN 403-compliant respiratory self-rescue devices provide multiple operational, safety, and organizational benefits. They ensure reliable protection during emergencies, increase employee confidence and minimize the risk of respiratory injury or fatality. Compliance shows adherence to internationally recognized safety practices, facilitating regulatory acceptance and market trust. Below are some of the key benefits:

- Ensures users are protected from toxic gases, smoke, and oxygen-deficient conditions during escape.

- Easy-to-use design allows immediate donning under stress, reducing response time.

- Materials and design provide reliable performance in harsh environments.

- Aligns with European and international occupational safety standards.

- Users can trust that the device will function correctly in emergencies.

- Minimizes misuse and ensures proper inspection and maintenance.

- Ergonomic design enables mobility during escape.

- Manufacturers producing EN 403-compliant devices gain global recognition.

- Reduces likelihood of injury or fatalities, supporting workplace safety programs.

- Can be used in combination with other personal protective equipment.

Market Trends

The global market for self-rescue respiratory devices is growing due to stricter workplace safety regulations, increased industrial and mining activities, and heightened awareness of emergency preparedness. Europe, North America and Asia-Pacific lead demand for EN 403-compliant devices. Recent trends include lightweight devices for easier transport, improved filtration technologies for broader gas coverage, compact ergonomic designs, and devices integrated with digital tracking for inspection and expiration monitoring. Companies adopting certified devices gain operational safety advantages and show commitment to employee protection.

Certification Process for EN 403 Implementation

- Conduct a gap analysis of existing self-rescue respiratory devices.

- Verify design, materials, and construction against EN 403 performance requirements.

- Perform dynamic and functional testing under simulated emergency conditions.

- Update marking and user instructions as per EN 403 specifications.

- Train employees on correct usage, inspection, and storage of self-rescue devices.

- Integrate device compliance into organizational safety management systems.

- Schedule regular inspections and maintenance to ensure ongoing compliance.

What is the certification timeline?

The certification timeline for EN 403 generally ranges from three to six months depending on whether the respiratory protective devices are existing models or newly developed. The process includes design verification, functional testing, documentation review, and employee training. For new devices, additional time may be required for prototype development, environmental testing, and adjustments based on test results. Organizations also need to factor in internal reviews and pre-audit preparations to ensure that all device specifications, instructions, and safety features fully comply with EN 403 requirements.

What is the certification cost?

The cost of achieving EN 403 compliance varies based on device complexity, testing requirements, and documentation needs. Major cost components include functional and environmental testing of devices, preparation of user manuals and labelling, and staff training for correct usage and maintenance. Additional expenses may arise from prototype development or modifications required to meet standard specifications. While the investment depends on the scale and scope of the certification effort, it ultimately supports workplace safety, reduces potential liability, and ensures regulatory recognition for self-rescue respiratory equipment.

How Pacific Certifications Can Help?

Pacific Certifications supports organizations in aligning with EN 403 by:

- Conducting gap assessments for self-rescue devices.

- Assisting with testing and performance verification under emergency conditions.

- Guiding marking, documentation, and instructions compliance.

- Providing employee training on usage, inspection, and maintenance.

- Integrating EN 403 compliance with broader safety management systems.

Contact support@pacificcert.com for guidance.

Training and Courses

- Lead Auditor Training: Audit compliance of respiratory protective devices and self-rescue systems.

- Lead Implementer Training: Implement EN 403-compliant devices and emergency protocols.

- Internal Auditor Training: Ensure ongoing compliance and device inspection routines.

Pacific Certifications provides accredited training programs. Contact support@pacificcert.com.

Frequently Asked Questions (FAQs)

- Are EN 403 devices reusable?

Some are reusable with proper inspection and maintenance, while others are single-use.

- Which industries require EN 403 devices?

Mining, chemical processing, confined spaces, industrial maintenance, and firefighting.

- How long does EN 403 protection last?

Typically 10–15 minutes, depending on device type and hazardous environment.

- Can EN 403 devices be used in extreme temperatures?

Yes, compliant devices maintain performance across expected workplace temperature ranges.

- What marking is required on EN 403 devices?

Manufacturer, model, serial number, expiration date, and protective duration.

- How often should devices be inspected?

Before each use and according to manufacturer recommendations.

Ready to get EN 403 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs