What is ISO 14644-1:2015?

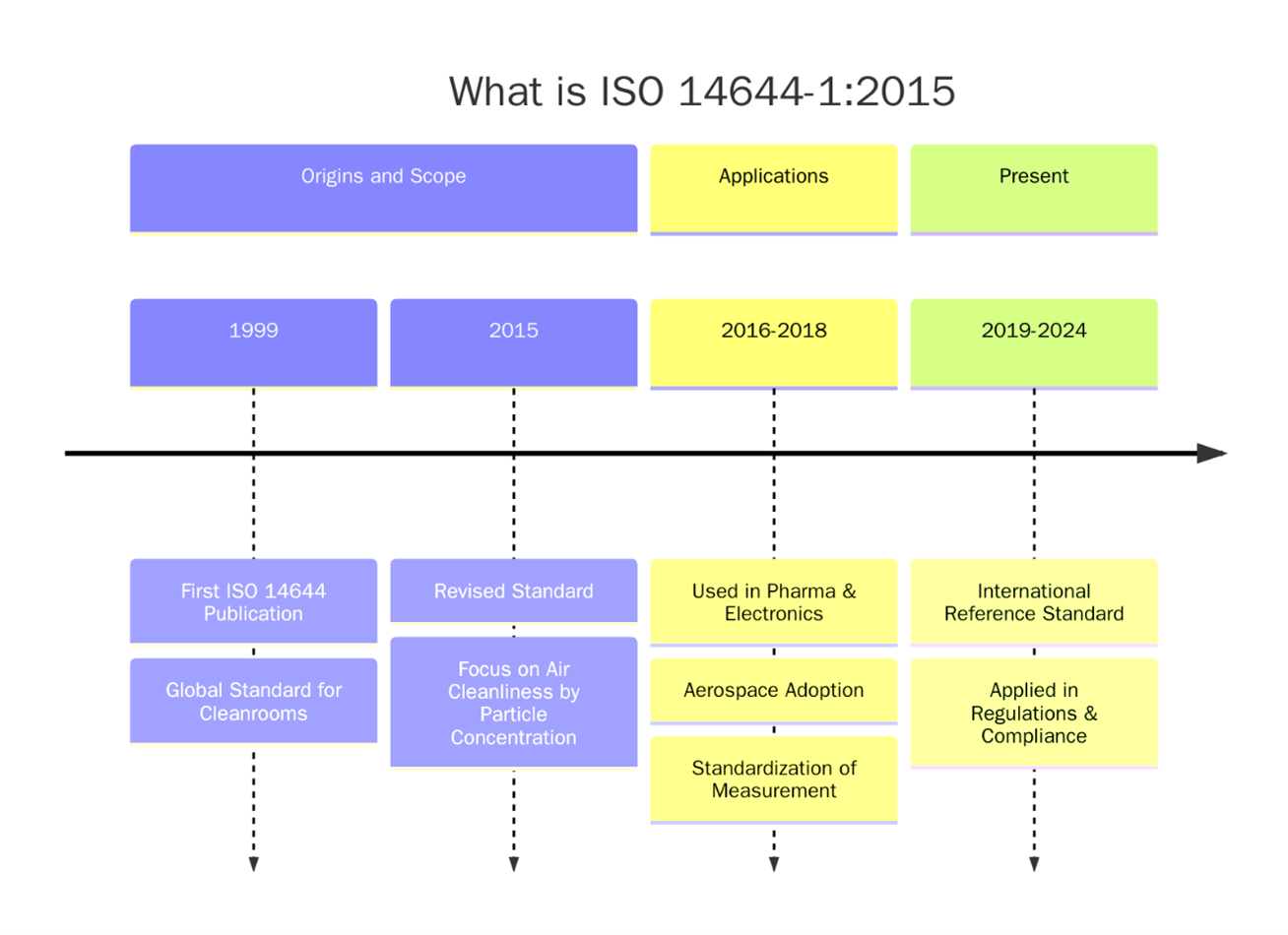

ISO 14644-1:2015 is an international standard that specifies the classification of air cleanliness in cleanrooms and other controlled environments. It defines the requirements for the measurement of airborne particle concentrations in these environments to ensure that conditions meet the necessary cleanliness standards for specific applications, such as in the pharmaceutical, healthcare, semiconductor, and biotechnology industries. This standard is essential for maintaining the integrity of processes and products that are sensitive to contamination, providing guidance on achieving and maintaining the desired cleanliness levels for different environments.

ISO 14644 sets out criteria for classifying cleanrooms according to the maximum allowable concentration of airborne particles, facilitating effective contamination control and consistent product quality.

For more information, contact us at support@pacificcert.com

Purpose

The purpose of ISO 14644 is to provide a standard method for classifying cleanrooms and controlled environments based on their cleanliness level. The standard helps organizations ensure that their environments meet the necessary cleanliness criteria, preventing contamination that could affect the safety, effectiveness, and reliability of products. This standard is crucial in industries where maintaining specific air quality and minimizing particulate contamination is essential to product quality and compliance with regulatory requirements.

Scope and Applicability

ISO 14644 applies to all cleanrooms and controlled environments, regardless of size or purpose. The standard is relevant for industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, food production, and healthcare, where even minute levels of airborne contamination can have significant effects on product quality and safety. It specifies how to measure and classify particle levels, providing a system to define cleanliness levels in environments where controlled air quality is critical to the success of operations. This standard helps organizations in these sectors to comply with regulatory guidelines and maintain operational efficiency by ensuring that air cleanliness levels are consistently monitored and maintained.

Key Definitions

- Cleanroom: A controlled environment where the concentration of airborne particles is maintained within specified limits to prevent contamination during manufacturing or research processes.

- Air Cleanliness Class: A classification system that defines the level of cleanliness in a cleanroom based on the maximum allowable concentration of airborne particles.

- Airborne Particles: Solid or liquid particles that are suspended in the air within a cleanroom or controlled environment.

- Controlled Environment: An environment where parameters like temperature, humidity, and airborne particle concentration are controlled to specific levels.

Clause-wise Structure of ISO 14644-1:2015

Clause Number | Title | Description |

Clause 1 | Scope | Defines the scope of the standard and specifies the environments it applies to. |

Clause 2 | Normative References | Lists the standards and documents referenced in ISO 14644. |

Clause 3 | Terms and Definitions | Provides key terms and definitions used in the standard for consistency. |

Clause 4 | Classification of Air Cleanliness | Specifies the classification system for cleanrooms based on airborne particle concentration. |

Clause 5 | Measurement of Airborne Particles | Describes the methods for measuring airborne particle concentrations. |

Clause 6 | Environmental Conditions | Sets the conditions under which particle concentration measurements should be conducted. |

Clause 7 | Application of Air Cleanliness Classes | Describes the various air cleanliness classes and their relevance in different applications. |

Clause 8 | Monitoring and Verification | Details the requirements for ongoing monitoring and verification of cleanliness levels in cleanrooms. |

What are the requirements of ISO 14644?

ISO 14644-1 requires that cleanrooms and controlled environments be classified according to the level of airborne particles present. To comply with this standard, organizations must ensure the following:

- Cleanrooms must be monitored for airborne particles, and measurements should be taken at specified locations and conditions to classify the cleanliness level accurately.

- The cleanroom must be classified according to the ISO 14644-1 classification system, which sets limits on the allowable concentration of particles of various sizes.

- The conditions for particle measurements must be controlled, including factors such as temperature, humidity, and airflow.

- Regular monitoring and verification must be conducted to ensure that cleanrooms continue to meet the required cleanliness standards.

For more information on standard requirements, contact us at support@pacificcert.com.

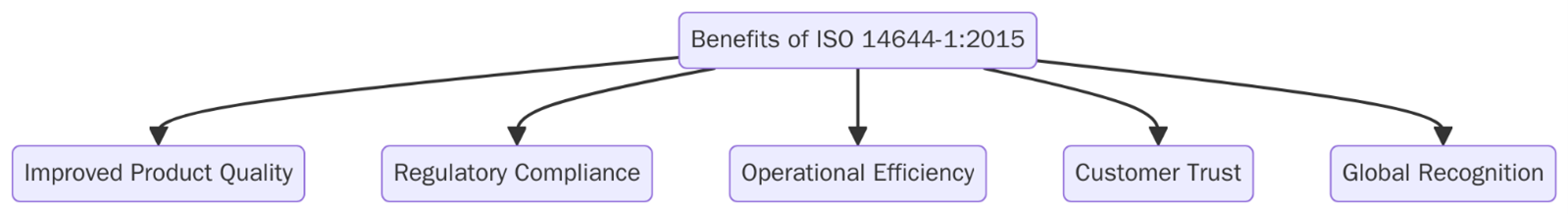

What are the benefits of ISO 14644-1:2015 Certification?

ISO 14644 certification offers several important benefits for organizations that operate cleanrooms and controlled environments. Below are some of the key advantages of obtaining ISO 14644 certification:

- Certification ensures that cleanrooms meet the necessary cleanliness levels, reducing contamination risks and improving product safety.

- Compliance with ISO 14644 helps organizations meet industry regulations and guidelines for cleanroom operations.

- Certification provides credibility in the global marketplace, facilitating trade and demonstrating commitment to quality standards.

- ISO 14644 helps organizations maintain consistent operational processes by monitoring and controlling airborne particle concentrations.

As industries continue to prioritize product safety and contamination control, the demand for cleanrooms and controlled environments is expected to increase significantly. ISO 14644 certification will be crucial for organizations in sectors like pharmaceuticals, biotechnology, electronics, and food safety, where even the slightest contamination can have severe consequences. As the need for higher standards in environmental control and cleanliness grows, the adoption of ISO 14644 will be essential for organizations aiming to stay competitive and compliant with global regulations.

Certification Process: ISO 14644

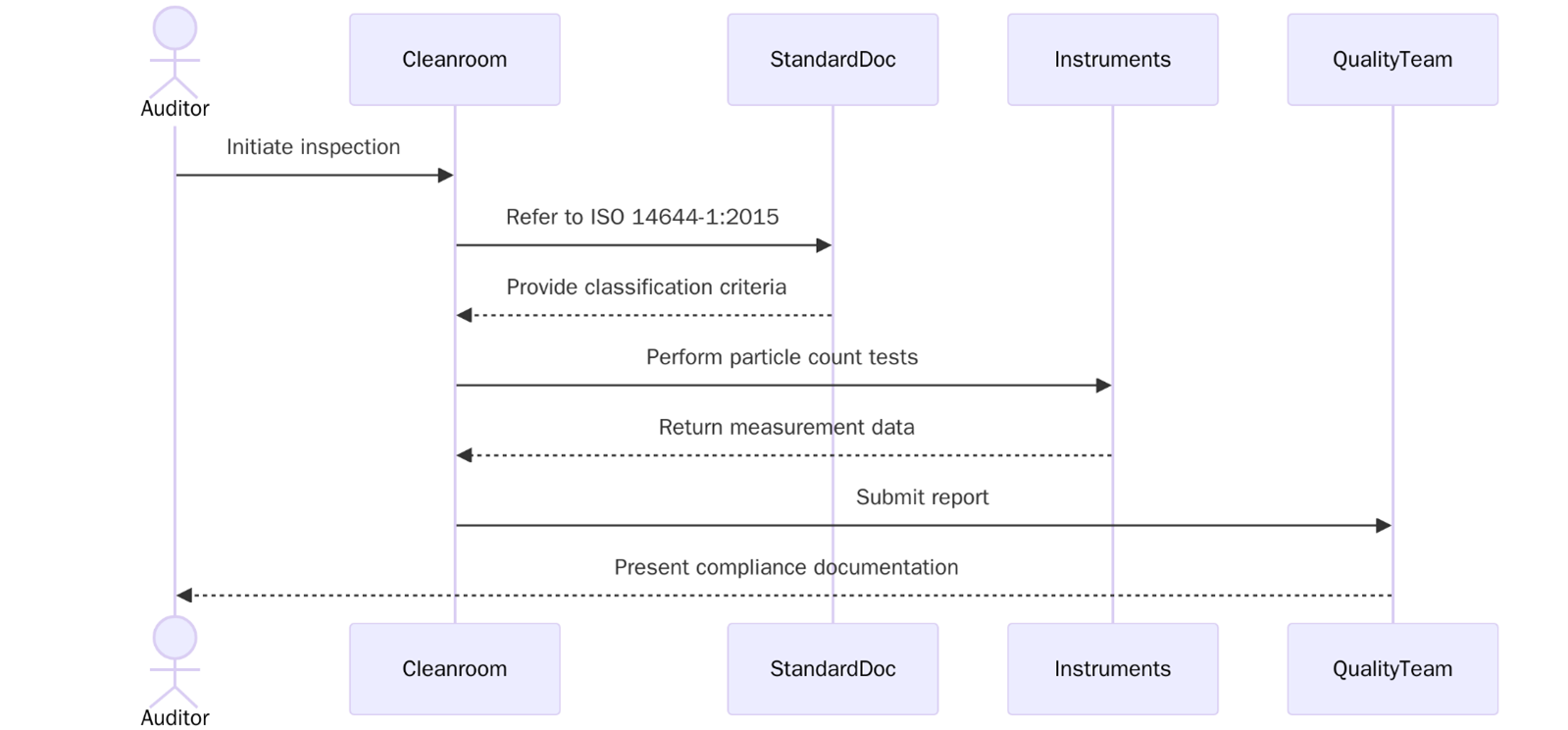

The certification process for ISO 14644 involves several key steps:

- Pre-Certification Assessment: A gap analysis to assess current cleanliness standards and identify areas for improvement.

- Documentation Review: Review of procedures and records related to cleanroom classification, particle measurement, and environmental control.

- Stage 1 Audit: Initial audit to verify that the cleanroom meets the necessary particle concentration and environmental control requirements.

- Stage 2 Audit: A more thorough on-site audit to assess the cleanroom’s ongoing compliance with the standard.

- Certification Decision: Certification is awarded if all requirements are met and the cleanroom meets the necessary classification levels.

- Ongoing Monitoring: Regular audits and recertification every three years to ensure continued compliance.

For audits and certification, contact support@pacificcert.com.

Timeline – ISO 14644-1:2015 Certification

The timeline for ISO 14644 certification spans several months. Initially, the pre-assessment and preparation phase takes around 1-2 months, during which the organization reviews and adjusts its practices to meet the standard’s requirements. The Stage 1 audit, which involves reviewing documentation and systems, takes around 1 month. The Stage 2 audit, a more comprehensive on-site assessment, lasts about 1-2 months. Certification issuance occurs within 3-6 months, depending on the audit outcomes and the organization’s readiness.

What is the cost of ISO 14644?

The cost of ISO 14644 certification varies depending on the size and complexity of the organization and its cleanroom operations. Costs mostly cover:

Audit Fees is the fee for the external audit process carried out by a certification body. Training Costs are the expenses for training personnel on the ISO 14644 standard and cleanroom management. Ongoing Maintenance Costs for ongoing monitoring and recertification, which are generally required every 3 years.

How Pacific Certifications Can Help?

At Pacific Certifications, we provide comprehensive auditing and certification services for ISO 14644. Our team of experts will guide you through the entire certification process, ensuring your cleanroom operations meet the necessary standards for particle concentration and environmental control. We offer:

- Stage 1 and Stage 2 audits to evaluate particle measurement systems and cleanroom classification.

- Objective conformity assessments aligned with ISO 14644.

- Certification issuance upon successful completion of the audit.

- Ongoing surveillance audits to ensure continued compliance.

- Support for multi-site or global operations.

For audits and certification, contact support@pacificcert.com.

ISO 14644-1-11 Training and Courses

Various training courses are available to help organizations comply with ISO 14644, including:

- Lead Auditor Training – Equips professionals to conduct external third-party audits.

- Lead Implementer Training – For those responsible for planning and executing ISO 14644-1-11 implementation.

- Internal Auditor Training– Preparing internal auditors for certification audits

Pacific Certifications provides accredited training programs. If your organization is looking for ISO training, our team is equipped to help you. Contact us at support@pacificcert.com.

Frequently Asked Questions (FAQs)

How long does it take to get ISO 14644 certification?

The certification process typically takes 3–6 months, depending on your organization’s preparedness and audit outcomes.

Is ISO 14644 certification mandatory for all cleanroom environments?

ISO 14644 is not legally required, but it is essential for ensuring that cleanrooms comply with international standards for cleanliness and particle control.

What are the main benefits of ISO 14644 certification?

Certification improves product quality, ensures regulatory compliance, enhances market access, and supports operational efficiency.

Can I apply for ISO 14644 certification without particle measurement systems in place?

No, organizations must have an established system for measuring airborne particles and maintaining cleanroom classification to achieve certification.

How often do I need to renew ISO 14644 certification?

ISO 14644-1:2015 certification is valid for three years, after which recertification is required.

Contact Us

If you need support with ISO 14644-1 certification, contact us at support@pacificcert.com.

Read More at: Blogs by Pacific Certifications