ISO Certifications for Motor Vehicle Manufacturing Businesses, Requirements and Benefits

The automotive industry thrives on precision and efficiency. ISO certifications for motor vehicle manufacturing offer a strong framework that ensures quality, compliance, and continual improvement. These standards are vital for manufacturers aiming to meet global demands while maintaining safety and environmental responsibilities.

ISO standards provide globally recognized benchmarks for quality, safety, and environmental performance. In the motor vehicle manufacturing sector, these certifications assure stakeholders—manufacturers, suppliers, and consumers—that the processes, products, and systems meet stringent requirements.

With the automotive sector experiencing technological innovations like electric vehicles (EVs) and autonomous driving, adherence to ISO standards ensures companies stay ahead in the competitive market. ISO certifications not only streamline processes but also address sustainability, safety, and consumer satisfaction.

If achieving ISO certification is your next goal, our team at Pacific Certifications is here to help you every step of the way. Contact us at support@pacificcert.com or call +91-8595603096 to begin your journey toward excellence in motor vehicle manufacturing.

Applicable ISO Standards for Motor Vehicle Manufacturing

Numerous ISO standards apply to motor vehicle manufacturing. Below are the most relevant ones that encompass quality, safety, environmental compliance, and innovation:

ISO 9001: Quality Management Systems: ISO 9001 establishes a framework for consistent quality management. In motor vehicle manufacturing, it ensures that products meet customer expectations while maintaining efficiency across the production cycle.

ISO/TS 16949 (Now IATF 16949): Automotive Quality Management: This technical specification, developed specifically for the automotive industry, integrates ISO 9001 requirements with sector-specific needs. It focuses on defect prevention, continuous improvement, and reducing waste in the supply chain.

ISO 14001: Environmental Management Systems: ISO 14001 helps motor vehicle manufacturers minimize environmental impacts. It emphasizes sustainable practices such as waste reduction, efficient resource use, and adherence to environmental laws.

ISO 45001: Occupational Health and Safety Management: Safety in manufacturing plants is critical. ISO 45001 addresses workplace hazards, reducing accidents and creating a safer environment for employees.

ISO 26262: Functional Safety: This standard deals with the safety of electrical and electronic systems in vehicles. With the rise of autonomous and semi-autonomous vehicles, ISO 26262 ensures the reliability and safety of these components.

ISO 50001: Energy Management: ISO 50001 provides a framework for optimizing energy use. It is particularly beneficial for automotive manufacturers aiming to reduce energy consumption and carbon footprints.

ISO 21434: Cybersecurity for Road Vehicles: In an age of connected vehicles, ISO 21434 focuses on cybersecurity risks. It ensures that manufacturers integrate robust security measures into vehicle systems and production processes.

ISO 19650: BIM for Information Management: This standard is pivotal for digital transformation in manufacturing, aiding effective management of building information models for facility planning.

Click here to find out more applicable standards to your industry

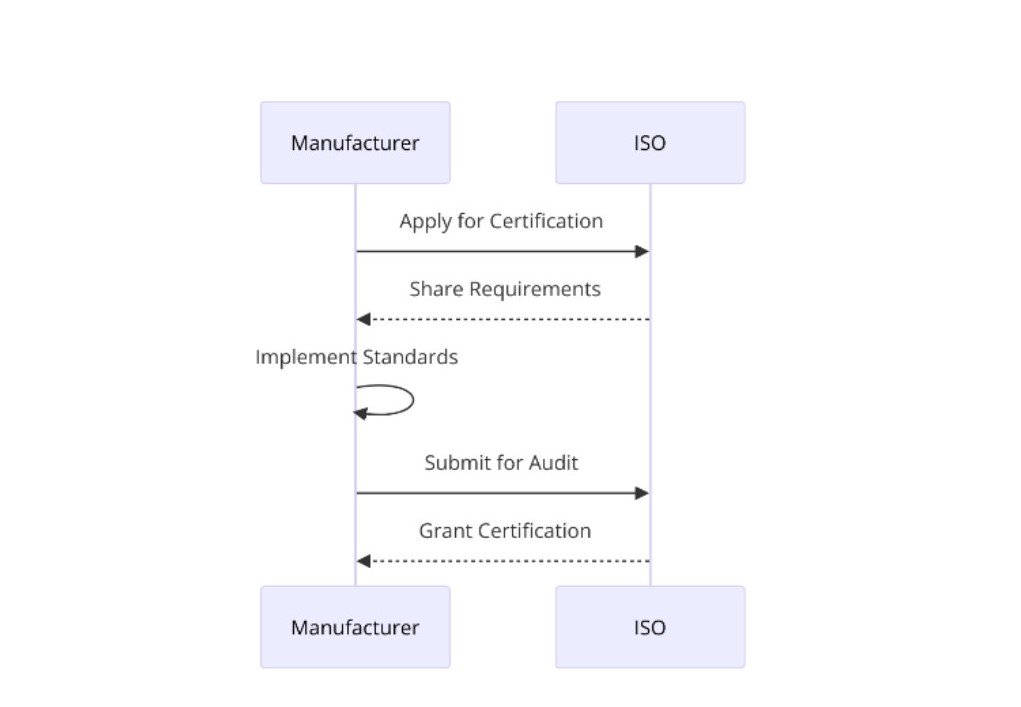

At Pacific Certifications, we specialize in auditing and issuing certifications for various ISO standards. Our expertise ensures a seamless certification process, enabling motor vehicle manufacturers to demonstrate compliance with global benchmarks. As an independent certification body, we uphold impartiality and deliver reliable services that add value to your organization.

Whether your focus is quality management, environmental sustainability, or functional safety, our auditors bring industry knowledge and expertise to evaluate your systems effectively.

Partner with Pacific Certifications to achieve your ISO certification goals efficiently and effectively. Contact us at support@pacificcert.com or call us directly at +91-8595603096 for personalized assistance.

Requirements of ISO Certifications for Motor Vehicle Manufacturing

Each ISO Certification has its own set of requirements to follow:

ISO 9001: Quality Management Systems Requirements

- Quality Objectives: Define clear, measurable quality objectives and a plan to achieve them.

- Customer Focus: Understand and meet customer requirements to enhance satisfaction.

- Documented Processes: Maintain updated documentation of all key processes, procedures, and policies.

- Leadership Commitment: Top management must demonstrate commitment to the quality management system (QMS).

- Risk-Based Thinking: Identify and mitigate risks affecting product or process quality.

- Performance Monitoring: Conduct regular internal audits, management reviews, and performance evaluations.

- Continuous Improvement: Implement corrective actions to address non-conformities and improve processes.

IATF 16949: Automotive Quality Management Requirements

- Advanced Product Quality Planning (APQP): Plan for quality during the design and development stages.

- Production Part Approval Process (PPAP): Validate that manufacturing processes consistently produce conforming products.

- Defect Prevention: Establish processes that prevent defects, such as Failure Mode and Effects Analysis (FMEA).

- Supply Chain Management: Ensure suppliers adhere to quality standards and maintain consistency.

- Statistical Process Control (SPC): Use statistical techniques to monitor and control production quality.

- Customer-Specific Requirements: Comply with unique requirements from automotive customers.

ISO 14001: Environmental Management Systems Requirements

- Environmental Policy: Develop a policy that demonstrates the organization’s commitment to environmental protection.

- Environmental Aspects: Identify how manufacturing processes interact with the environment and assess their impacts.

- Compliance Obligations: Meet legal, regulatory, and other requirements related to environmental performance.

- Operational Control: Implement procedures to manage significant environmental impacts, such as waste disposal.

- Monitoring and Measurement: Track environmental performance through defined metrics and regular assessments.

- Continual Improvement: Enhance environmental performance by reducing emissions, waste, and resource consumption.

ISO 45001: Occupational Health and Safety Management Requirements

- Hazard Identification: Assess workplace risks and hazards and document findings.

- Worker Participation: Involve employees in safety management activities and decision-making.

- Safety Objectives: Define measurable health and safety goals aligned with business operations.

- Emergency Preparedness: Plan for emergencies with clear procedures, training, and resources.

- Legal Compliance: Adhere to laws and regulations governing workplace health and safety.

- Incident Reporting: Document and investigate incidents to prevent recurrence.

- Safety Audits: Regularly audit health and safety processes for effectiveness.

ISO 26262: Functional Safety Requirements

- Safety Lifecycle Management: Define and document the lifecycle phases for safety-critical systems.

- Hazard and Risk Analysis: Identify potential safety hazards and analyze associated risks.

- Safety Goals: Establish clear safety objectives based on risk assessment.

- Validation and Verification: Perform thorough testing and reviews to confirm system safety.

- Supplier Management: Ensure suppliers meet safety requirements for critical components.

- Functional and Technical Safety Concepts: Develop technical solutions to achieve safety objectives.

- Software and Hardware Integration: Validate the compatibility and safety of integrated systems.

ISO 50001: Energy Management Systems Requirements

- Energy Policy: Create a policy emphasizing energy efficiency and performance.

- Energy Review: Assess energy use patterns, identify areas of inefficiency, and establish baselines.

- Energy Objectives and Targets: Set goals for reducing energy consumption and improving efficiency.

- Monitoring and Measurement: Track energy performance with measurable indicators.

- Operational Controls: Implement strategies to manage significant energy uses effectively.

- Competence and Awareness: Train employees on energy management practices.

- Improvement Plan: Use findings from energy reviews to plan and implement performance improvements.

ISO 21434: Cybersecurity for Road Vehicles Requirements

- Risk Management: Identify, assess, and manage cybersecurity risks in vehicle systems.

- Security by Design: Integrate cybersecurity measures during the design and development phases.

- Incident Response Planning: Develop a robust plan for identifying, reporting, and responding to cyber threats.

- Secure Supply Chain: Ensure cybersecurity is maintained throughout the supply chain.

- Monitoring and Updating: Monitor systems for vulnerabilities and deploy updates to address threats.

- Documentation: Maintain thorough records of cybersecurity processes and incidents.

- Compliance with Regulations: Align with applicable regional or global cybersecurity laws and guidelines.

These requirements ensure motor vehicle manufacturers maintain excellence in quality, safety, energy efficiency, and cybersecurity while addressing environmental and operational challenges. Following these detailed requirements will enable organizations to achieve and maintain ISO certifications, reinforcing their credibility and operational efficiency.

ISO standards ensure your motor vehicle manufacturing processes are compliant, efficient, and sustainable. Reach out to support@pacificcert.com or call us at +91-8595603096 to get certified today.

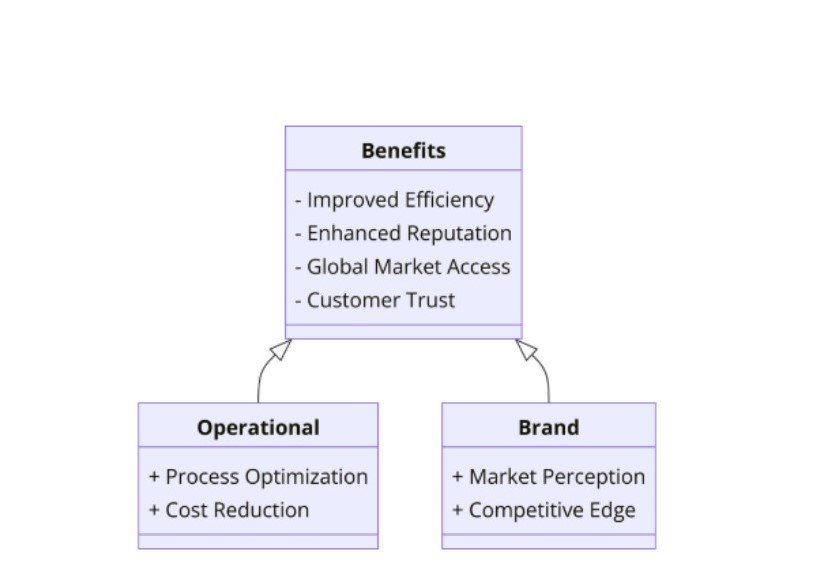

Benefits of ISO Certifications for Motor Vehicle Manufacturing

Implementing ISO standards provides far-reaching benefits for motor vehicle manufacturers. Some of the key advantages include:

Product Quality: ISO standards ensure that manufacturing processes are designed to produce high-quality vehicles consistently, meeting both customer and regulatory expectations.

Safety: From workplace safety under ISO 45001 to functional safety in vehicle systems with ISO 26262, these standards mitigate risks for workers and end-users alike.

Environmental Sustainability: ISO 14001 and ISO 50001 guide manufacturers toward sustainable practices, reducing waste, emissions, and energy consumption.

Market Access: ISO certifications are often prerequisites for entering global markets. They demonstrate compliance with international regulations, facilitating smoother trade.

Cost Efficiency: Streamlining processes under ISO guidelines reduces waste, defects, and resource usage, leading to significant cost savings.

Reputation and Trust: An ISO-certified organization commands trust from customers, suppliers, and partners, reinforcing its brand reputation.

The automotive industry in 2024 is navigating an era of transformation, driven by advancements in EVs, AI, and smart manufacturing. According to a recent report, demand for ISO 26262 and ISO 21434 is expected to rise, reflecting the growing focus on vehicle safety and cybersecurity.

Emerging markets are increasingly adopting ISO certifications to compete globally, and governments are encouraging compliance with environmental standards like ISO 14001 to align with net-zero targets. Manufacturers embracing these trends are likely to stay competitive and resilient.

ISO certifications are more than just a compliance tool—they are a pathway to excellence in the motor vehicle manufacturing industry. Whether you are looking to improve quality, enhance safety, or reduce environmental impact, Pacific Certifications is here to help.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Motor Vehicle Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Motor Vehicle Manufacturing

ISO certifications are internationally recognized standards that ensure quality, safety, and environmental compliance in the motor vehicle manufacturing sector.

ISO 9001 ensures consistent quality management, helping manufacturers meet customer expectations while optimizing processes.

ISO 26262 focuses on the functional safety of electrical and electronic systems, ensuring vehicles meet high safety standards.

Yes, Pacific Certifications offers auditing and certification services to help manufacturers meet ISO standards effectively.

ISO 14001 helps manufacturers implement eco-friendly practices, reducing their environmental impact and promoting sustainability.

ISO certifications demonstrate compliance with international benchmarks, facilitating access to global markets and enhancing brand trust.

Read More at: Blogs by Pacific Certifications