What is ISO 10427-1:2024?

ISO 10427-1:2024 provides guidance for the design, testing and performance of bow-spring casing centralizers, critical components in oil and gas cementing operations. Centralizers ensure proper placement of casing in the wellbore, enabling effective cementing that supports well integrity and zonal isolation. Correct centralizer selection and performance directly impact cement sheath uniformity, preventing gas migration, casing eccentricity and operational failures. This standard helps manufacturers, drilling contractors and operators ensure that centralizers meet international quality and performance benchmarks for safe and efficient well construction.

Purpose

The purpose of ISO 10427-1:2024 is to standardize the performance, testing and material requirements for casing centralizers, particularly bow-spring types, to ensure well integrity during cementing operations. By adhering to these guidelines, organizations can verify centralizer reliability, reduce operational risk and maintain compliance with industry best practices. The standard supports consistent quality across suppliers and operations, providing assurance that centralizers perform as intended under downhole conditions.

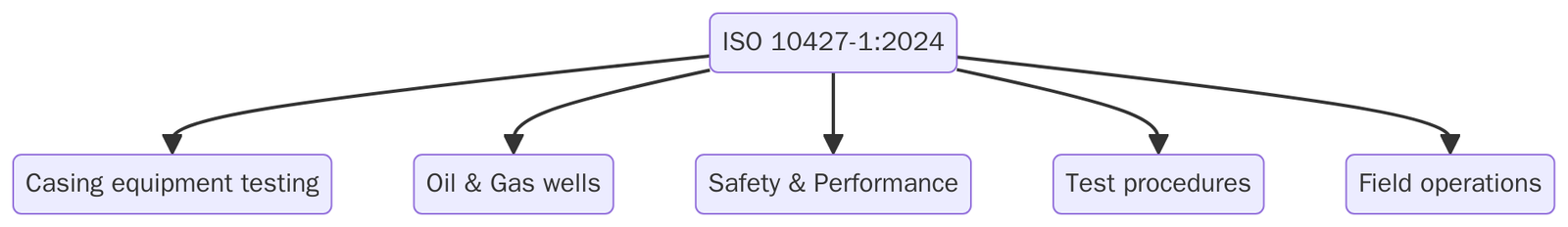

Scope and applicability

ISO 10427-1:2024 applies specifically to casing centralizers used in drilling, well construction and cementing operations. It is relevant for:

- Manufacturers of bow-spring centralizers, ensuring standardized design, material selection and testing.

- Drilling contractors responsible for selecting, deploying and monitoring centralizers in wells.

- Operators overseeing well integrity, cementing quality and regulatory compliance.

The standard covers centralizers for all well types, including conventional and high-pressure high-temperature (HPHT) wells and provides guidance for consistent QA/QC, material verification and performance assessment.

Key definitions

- Restoring Force: The force exerted by the bow-spring to centralize casing in the wellbore.

- Starting Force: The minimum force required to move the centralizer past restrictions in the wellbore.

- Bow-Spring Centralizer: A mechanical device with spring-loaded bow elements designed to maintain casing alignment in the wellbore.

- Zonal Isolation: The effective sealing of formations to prevent fluid migration between zones after cementing.

Clause-wise breakdown

| Clause | Title | Description |

| 1 | scope | Defines applicability for bow-spring centralizers in petroleum operations. |

| 2 | normative references | Lists referenced API, ISO and industry standards for centralizer performance. |

| 3 | terms and definitions | Provides definitions critical to centralizer design and testing. |

| 4 | materials | Specifies material strength, corrosion resistance and alloy selection. |

| 5 | dimensional requirements | Provides tolerance and geometry requirements for casing centralizers. |

| 6 | performance testing | Aligns with API RP 10D for restoring force, starting force and mechanical function. |

| 7 | quality documentation | Requires traceability, inspection records and verification of supplier QA/QC. |

| 8 | compliance and verification | Guidelines for internal and third-party verification of performance and quality. |

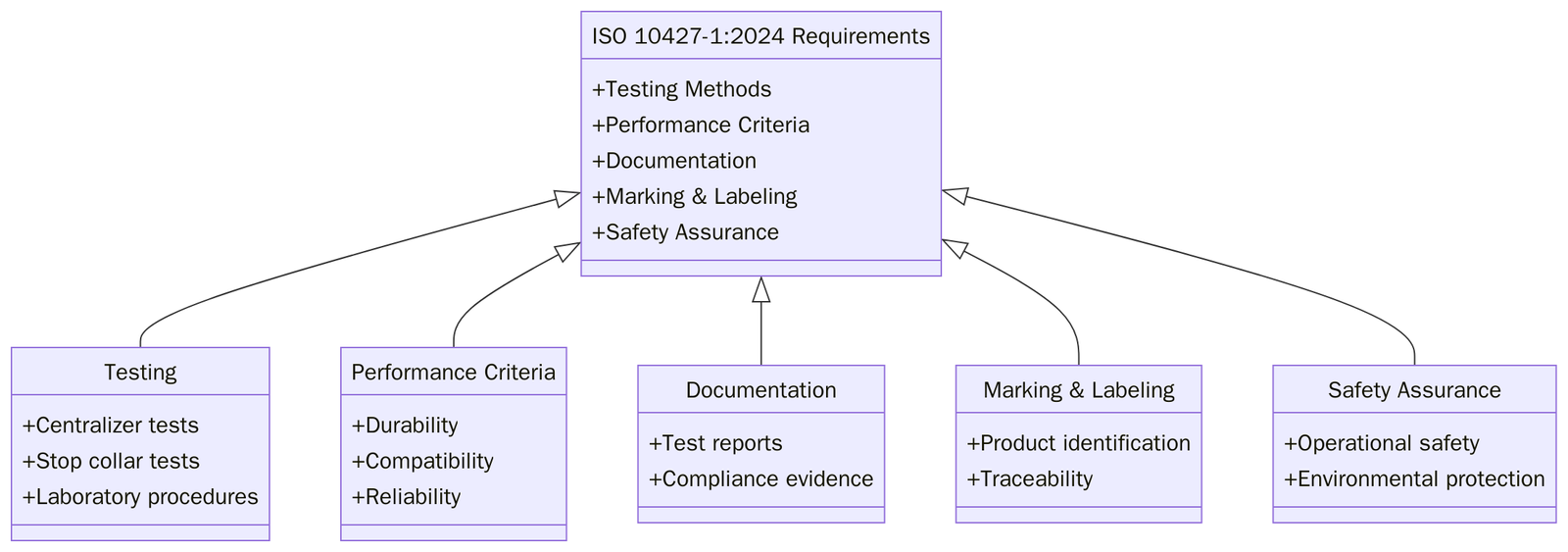

What are the requirements of ISO 10427-1:2024?

Organizations deploying bow-spring centralizers must ensure compliance with material, dimensional and performance requirements to guarantee well integrity. These requirements establish uniform standards across manufacturing and operational processes, enabling consistent performance. Below are some of the key requirements:

- Materials must meet strength, corrosion resistance and durability criteria suitable for downhole conditions.

- Dimensional tolerances must comply with specified ranges to ensure proper casing centralization.

- Centralizers must undergo performance testing, including restoring force and starting force, aligned with API RP 10D.

- Quality documentation must include material certifications, inspection records and supplier QA/QC processes.

- Centralizers must be verified for operational compatibility with target casing sizes and well conditions.

- Procedures for periodic review and testing of centralizers should be established to maintain reliability.

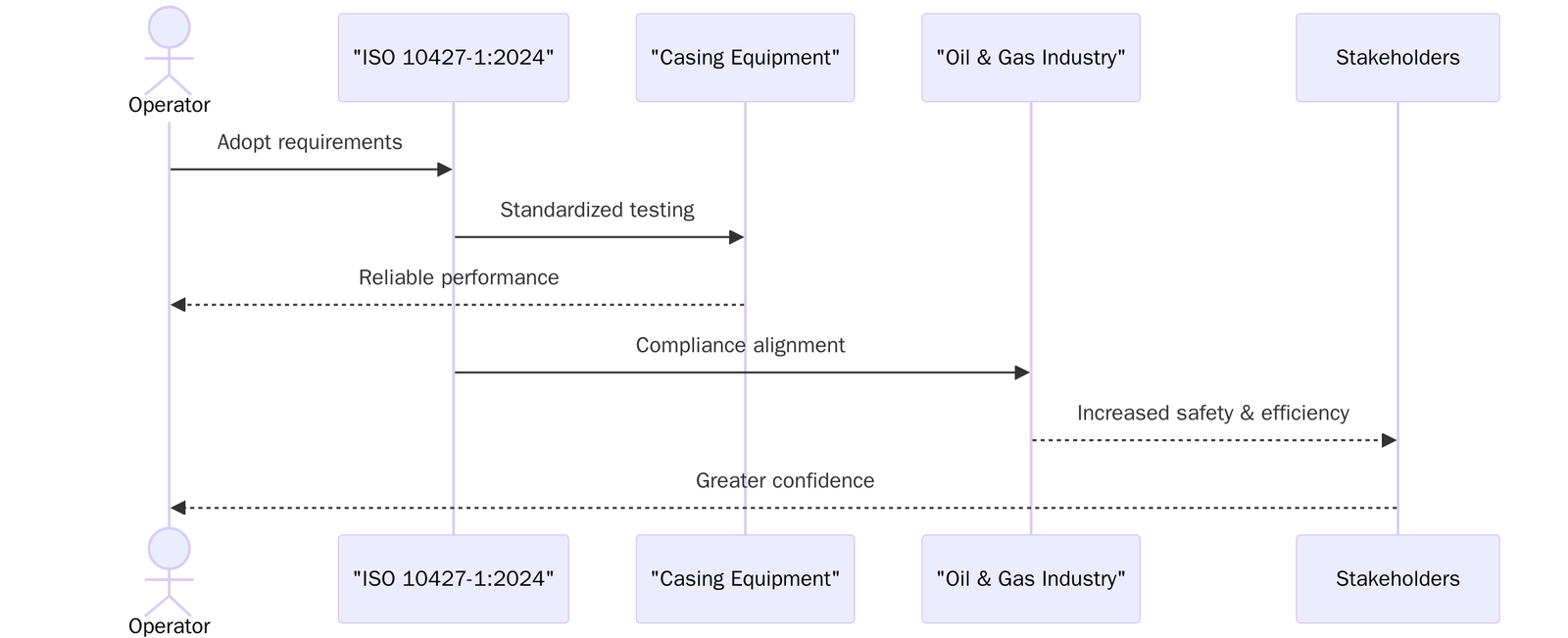

What are the benefits of ISO 10427-1:2024?

Implementing ISO 10427-1:2024 delivers multiple operational, safety and quality advantages. Below are some of the key benefits:

- improved cement sheath placement and uniformity

- reduced risk of gas migration or channelling in the wellbore

- standardized QA/QC for centralizer suppliers and manufacturers

- enhanced safety and reliability of well completions

- consistent performance across different wells and operators

- reduced operational downtime and rework costs

- increased confidence in high-pressure, high-temperature (HPHT) applications

The petroleum industry is increasingly using high-performance alloys, composite materials and digital QA/QC systems in centralizer design and manufacturing. HPHT wells demand centralizers that withstand extreme temperature and pressure conditions, while integrated monitoring tools allow real-time verification of restoring and starting forces. Advances in simulation and testing methods are helping manufacturers optimize bow-spring designs for improved cementing outcomes and better well integrity.

Certification process

- Conduct a gap assessment to compare existing centralizer design, materials and testing against ISO 10427-1:2024.

- Review and update material selection for corrosion resistance and downhole performance.

- Perform dimensional verification to ensure tolerances are within specification.

- Conduct performance testing, including restoring and starting force measurements aligned with API RP 10D.

- Maintain quality documentation, including supplier QA/QC records and inspection reports.

- Engage internal or third-party auditors to verify compliance.

- Implement continuous monitoring and improvement procedures for new or modified centralizer designs.

What is the certification timeline?

The timeline for ISO 10427-1:2024 alignment depends on the number of centralizer models, manufacturing complexity and testing requirements. Smaller manufacturers may complete alignment in 2–3 months, while larger suppliers with multiple product lines and offshore operators may require 4–6 months. This includes gap assessment, material verification, performance testing, documentation and internal or third-party audit processes.

What is the certification cost?

Costs vary depending on the number of centralizer models, material testing, performance verification and supplier QA/QC requirements. Expenses include internal preparation, testing equipment, documentation, training and audit fees if third-party verification is required. Investing in ISO 10427-1:2024 compliance reduces operational risk, improves well integrity and enhances the reliability and reputation of centralizer suppliers.

How Pacific Certifications can help?

Pacific Certifications supports organizations with ISO 10427-1:2024 alignment:

- conducting gap assessments for centralizer designs and operational procedures

- reviewing material, dimensional and performance testing documentation

- providing training for personnel involved in testing, inspection and QA/QC

- supporting internal or third-party verification of compliance

- guiding manufacturers and operators to meet industry best practices and regulatory expectations

Contact support@pacificcert.com to schedule certification support or training.

Training and courses

- Lead Auditor Training: prepares auditors for offshore safety and operational inspections

- Lead Auditor Training: guides personnel responsible for establishing or improving compliance and safety systems

- Internal Auditor Training: develops internal auditors to evaluate offshore structures, equipment and procedures

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 14027 training, our team is equipped to help you. Contact us at support@pacificcert.com.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs