Introduction

Baden-Württemberg’s Württemberg region sits at the heart of Germany’s industrial southwest, with a dense ecosystem of automotive OEMs and suppliers, precision engineering, machinery and high-value manufacturing. Mechanical engineering, car production and electrical equipment together generate roughly two-thirds of the region’s manufacturing revenue and employ a large share of the workforce. From 2026 to 2027, forecasts point to modest but stabilizing growth for Baden-Württemberg: research from regional analysts expects real GDP to grow by around 0.7 percent in 2026 and about 1.5 percent in 2027, after a period of near-stagnation and pressure on the auto and machinery sectors.

For automotive OEMs and Tier-1s, engineering and machinery companies, precision-parts manufacturers, battery and e-mobility suppliers and software or IT service providers, ISO certification in Württemberg supports the way customers qualify vendors and manage risk. ISO 9001 (Quality Management), ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health & Safety), IATF 16949 (automotive quality), ISO/IEC 27001 (data protection and information security) and ISO 50001 (energy management) help teams show that quality, safety, environment, data protection and energy use are controlled rather than assumed.

Share your scope and sites in Württemberg with Pacific Certifications and we will help you achieve ISO certification in Württemberg. We will map accreditation coverage, audit timelines and Stage 1 and Stage 2 audit windows that align with model cycles, project milestones and any integrated ISO 9001, ISO 14001, ISO 45001, ISO/IEC 27001 or ISO 50001 certification programs.

Economic context and industry overview

If Baden-Württemberg were a country, its economy would be comparable in size to Sweden’s, with GDP estimated above €630 billion and manufacturing contributing over 30 percent of gross value added. From 2023 to 2025, weak global demand and transformation pressure in the automotive and machinery cluster kept growth close to zero. However, current projections suggest real GDP growth around 0.7 percent in 2026 and a pickup toward roughly 1.5 percent in 2027 as supply chains adjust, interest rates ease and investment in e-mobility, digitalization and energy-transition projects continues.

Against this backdrop, quality management, environmental management, occupational health & safety, automotive quality, data protection and energy management become direct levers for competitiveness, tender success and innovation funding.

Why ISO certification in Wurttemberg matters for automotive and engineering?

OEMs, Tier-suppliers, machinery builders, precision-parts manufacturers and software firms in Württemberg all face intensive vendor assessments from global customers, finance providers and regulators. These stakeholders expect structured systems and traceable records, not just presentations. ISO certification in Württemberg gives companies structured proof that quality, safety, environment, data security and energy performance are under control.

ISO 14001 and ISO 45001 help manage emissions, waste, chemicals, site safety and contractor work on shop floors, test tracks, logistics hubs and construction or retrofit projects. IATF 16949 sits on top of ISO 9001 for automotive quality, focusing on defect-prevention, traceability and customer-specific requirements across the vehicle supply chain.

For data-driven operations, ISO/IEC 27001 supports data protection and information-security governance around connected vehicles, manufacturing networks and cloud services, while ISO 22301 supports continuity for critical engineering, logistics and IT functions. ISO 50001 helps energy-intensive plants, test facilities and data centers manage energy performance, which links directly to cost and climate targets.

Which ISO standards do Wurttemberg industries need most? standards by sector

| Industry focus | Commonly requested standards | Why they matter |

| Automotive OEMs and Tier-suppliers | ISO 9001, IATF 16949, ISO 14001, ISO 45001, ISO 50001 | Automotive quality, process stability, site safety, environmental management and energy management across plants and logistics |

| IT, software, digital platforms and data centers | ISO/IEC 27001, ISO 22301, ISO/IEC 20000-1, ISO 9001 | Data protection and information security, continuity of services, IT service quality and customer-facing quality management |

| Energy, utilities and infrastructure projects | ISO 9001, ISO 14001, ISO 45001, ISO 50001, ISO 22301 | Quality and safety on grid and infrastructure projects, environmental management and energy management, continuity for critical services |

| Medical technology and laboratories | ISO 9001, ISO 13485, ISO 15189, ISO/IEC 17025 | Device quality, lab competence and reliable results for regulated healthcare markets |

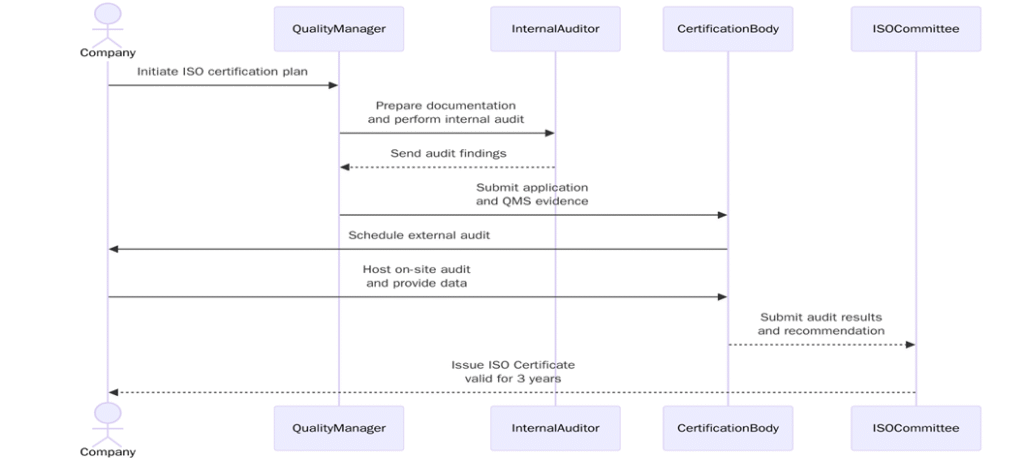

Certification process in Wurttemberg

The ISO certification process in Württemberg begins with preparation. Your ISO certification implementation roadmap should follow how work currently runs in development centers, plants, test labs, warehouses, data centers and project offices so that you build audit-readiness without asking teams to maintain a second, “for audit only” system. Below are the steps to consider:

- List products, services, sites, headcount and high-risk processes so the scope is clear and audit time is realistic for automotive, engineering, manufacturing and digital operations.

- Map processes end to end so handoffs, records and responsibilities are visible from development and sourcing through production, logistics, installation, support and decommissioning.

- Set policy and measurable objectives linked to customer and OEM requirements, legal or regulatory duties, climate and safety targets, data-protection expectations and internal risk priorities.

- Build or refine procedures and work instructions that match how teams actually work on lines, cells, test stands and projects, with forms and templates kept lean and usable.

- Keep permits, licenses, inspection reports, customer letters, calibration and monitoring records organized for quick verification at local, group or global audits.

What are the requirements of ISO certifications in Wurttemberg?

ISO certification requirements checklist for Württemberg should mirror the way automotive, engineering and manufacturing work actually runs in plants, test and prototyping centers, engineering offices, data centers and logistics operations so records stand up in audits, inspections and customer reviews. Below are the key requirements:

- Scope aligned to products or services, processes and sites, including multi-site programs that cover headquarters, development centers, production plants, service hubs and logistics locations.

- Controlled documents and records that match practice, with clear version-control, access rules and change-history visible to users and auditors in each site and function.

- Risk assessment with operational controls for real hazards and issues such as machine safety, robotics and automation, chemical handling, contractor work, cyber-risk, data protection, energy use and change management.

- Competence matrices and training records for process owners and high-risk roles in production, maintenance, engineering, IT, HSE, quality and customer-facing teams.

- Legal and other requirements register with permits, inspections, calibrations, monitoring data and supplier compliance evidence linked to product-safety law, environmental regulation, health and safety rules, data-protection law and sector-specific codes.

What are the business benefits of ISO certification in Wurttemberg? competitive advantages and ROI

When used properly, ISO certification in Württemberg should accelerate vendor approvals, support framework and long-term supply agreements, and protect margins by reducing defects, rework and unplanned downtime. The business benefits and ROI come from fewer surprises, clearer data and stronger positioning with OEMs, Tier-1s and global customers. Below are the key benefits:

- Faster pre-qualification in OEM and Tier-1 supplier portals, framework agreements, public procurement and energy or infrastructure tenders where ISO 9001, ISO 14001, ISO 45001 or IATF 16949 are baseline expectations.

- Traceable data for investigations, recalls, warranty analysis, ESG summaries and due diligence by investors, lenders and partners.

- Stronger supplier and contractor oversight through audits, KPIs and corrective actions across machining, surface treatment, logistics, IT, cleaning, waste and energy services.

- Measured gains in energy use, waste, emissions, uptime and yield in plants, labs and data centers, which link directly to energy management and climate commitments.

- Stronger signals of reliability, automotive quality and data protection for buyers who compare ISO and IATF status across competing suppliers.

Market Trends

Current analyses show that Baden-Württemberg’s economy will likely stay in a “slow growth” mode in 2026 with real GDP around 0.7 percent, before picking up toward roughly 1.5 percent growth in 2027 as the automotive and machinery sectors adapt to electrification, software-defined vehicles and new trade patterns. At the same time, the state’s climate and mobility targets call for sharp growth in electric and climate-neutral vehicles by 2030 and 2040 and a doubling or tripling of public-transport use, which reinforces demand for energy management, environmental management and safety systems in plants, fleets and infrastructure.

Automotive, mechanical engineering and electrical engineering are expected to invest heavily through 2026 and 2027 in electrified powertrains, batteries, power electronics, software, connectivity and Industry 4.0. Alongside technical change, OEMs and global customers continue to tighten requirements on quality management, occupational health & safety, environmental management, data protection and energy management, which is pushing more suppliers toward integrated ISO 9001, ISO 14001, ISO 45001, IATF 16949, ISO/IEC 27001 and ISO 50001 certification programs.

Common ISO certification challenges in Wurttemberg (and how to overcome them)

Common ISO certification challenges in Württemberg arise from transformation pressure, tight labor markets and complex supply chains. The main hurdles usually are:

- Budgeting time and funds for certification and system upkeep while managing parallel transformation programs around e-mobility, digitalization, automation and energy transition.

- Treating ISO and IATF as paperwork exercises in some teams, which creates gaps between formal procedures and what actually happens on lines and projects.

- Limited internal audit capacity or process owners who can connect ISO and IATF clauses to real shop-floor, test, project and IT risks.

- Gaps in document control, internal audits, corrective-action discipline and record keeping across multi-site and multi-company supply networks.

- Complex, multi-tier supply chains and outsourced processes that make it harder to gather evidence and keep controls consistent from Tier-1 to Tier-3 suppliers.

ISO certification cost in Wurttemberg: pricing guide, factors and budget planning

ISO certification cost in Württemberg varies by organization profile. Your ISO certification price depends on headcount and risk level, number of sites (single-site versus multi-site), standards chosen (for example ISO 9001, ISO 14001, ISO 45001, IATF 16949, ISO/IEC 27001, ISO 50001), and the mix between on-site and remote audit activities.

Your proposal from Pacific Certifications will itemize Stage 1, Stage 2 and surveillance days, explain on-site versus remote activities and highlight any multi-site efficiencies so leadership and finance teams can plan clearly.

For a personalized quote on ISO 9001, ISO 14001, ISO 45001, IATF 16949, ISO/IEC 27001, ISO 50001 or related ISO certification cost in Württemberg, contact support@pacificcert.com and request an ISO 9001 certification cost estimate for your operations in Germany.

How long does ISO certification take in Wurttemberg? timeline, milestones and schedules

ISO certification timeline in Württemberg depends on document and record readiness, the speed of closing Stage 1 findings, single versus multi-site scope and whether the program is single-standard or integrated. Planning around model launches, shutdowns, investment gates, fiscal year-end and key OEM or customer audits also shapes the schedule.

A prepared single site such as one plant, test center, engineering office, warehouse or data center can often move from application to decision within one audit cycle once gaps are closed. Multi-site or integrated programs, such as combined ISO 9001, ISO 14001 and ISO 45001 certification or IATF 16949 with ISO 14001 and ISO 45001, need more sampling and planning time, especially where several plants, countries or partners are involved.

ISO standards most requested by buyers in Wurttemberg: industry-specific selection guide

| Standard | Typical drivers in Württemberg |

| ISO 9001 | Supplier approval for automotive, engineering, machinery, electronics, IT and service organizations |

| IATF 16949 | Automotive quality requirements for OEMs and Tier-suppliers, including defect-prevention and customer-specific clauses |

| ISO 14001 and ISO 45001 | Environmental management and occupational health & safety discipline for plants, projects, depots and test facilities |

| ISO/IEC 27001 and ISO 22301 | Data protection, information security and continuity for connected vehicles, industrial IT, software and digital platforms |

| ISO 50001 | Energy management for energy-intensive plants, test rigs, data centers and infrastructure |

| ISO 13485, ISO 15189 and ISO/IEC 17025 | Regulated device and lab quality for medical technology and testing services |

How Pacific Certifications can help?

Pacific Certifications provides ISO certification services in Württemberg for automotive OEMs and suppliers, mechanical and plant engineering firms, precision-manufacturing and machining shops, electrical and electronics companies, IT and software providers, data centers, energy and infrastructure operators and medical-technology or laboratory organizations.

Our team works under recognized accreditation and is used to plant-floor, test-track, lab, data-center and project-site realities as well as OEM, Tier-1, regulator and investor questions. Our certificates are accepted by procurement portals and international customers and we are recognized by ABIS.

Request your free ISO certification quote, ISO 9001 cost estimate, ISO 14001 and ISO 45001 audit plan, IATF 16949 proposal and integrated ISO certification roadmap for Württemberg. We will help you map Stage 1 and Stage 2 audit timelines and compliance requirements for your organization. Contact us at support@pacificcert.com or visit www.pacificcert.com.

Accredited training programs

Pacific Certifications provides accredited ISO training courses in Württemberg for ISO 9001, ISO 14001, ISO 45001, IATF 16949, ISO/IEC 27001, ISO 22301, ISO 50001, ISO 13485 and ISO/IEC 17025. Our ISO certification training programs develop internal-auditor and implementation capability across automotive, engineering, manufacturing, electronics, IT, energy and medical-technology sectors.

- Lead Auditor Training: for professionals who audit these systems in OEMs, suppliers, engineering firms, plants and service organizations.

- Lead Implementer Training: for personnel who design, build or improve systems in plants, test and development centers, warehouses, labs, utilities, IT and digital platforms.

These programs run online or on-site, depending on client needs, under ISO/IEC 17024 for personnel certification.

FAQs

How long does ISO certification usually take in Württemberg?

For a ready single site, initial ISO certification often takes about one audit cycle once gaps are closed, while multi-site or integrated programs can take several additional months.

Which industries in Württemberg gain the most from ISO certification?

Automotive, mechanical and plant engineering, precision manufacturing, electronics, IT and data centers, energy and medical technology see the strongest benefits in tenders and global supply chains.

What is the difference between ISO 9001 and IATF 16949 for automotive companies?

ISO 9001 sets the general quality management framework, while IATF 16949 adds automotive-specific requirements on defect-prevention, traceability and customer-specific needs.

Which standards support data protection and information security in Württemberg?

ISO/IEC 27001 supports information-security management, often combined with ISO 22301 for continuity and ISO/IEC 20000-1 for IT-service quality.

How does ISO 50001 help manufacturing and engineering firms in the region?

ISO 50001 provides a structure to measure and manage energy use in plants, test facilities and data centers so teams can identify savings and support climate targets.

Can ISO and IATF audits be partly remote for Württemberg sites?

Yes, document reviews and many interviews can be conducted remotely, with focused on-site visits for lines, test areas and higher-risk processes.

Do smaller engineering or machining SMEs in Württemberg qualify for ISO certification?

Yes, SMEs can be certified, with audit time and sampling scaled to their size and risk while accreditation rules and impartiality are maintained.

What should we prepare before a Stage 1 audit?

You should have scope, process maps, risk assessments, policy and objectives, competence records, controlled procedures and at least one internal audit and management review completed.

How transparent is ISO certification pricing in Württemberg?

Pacific Certifications provides a documented proposal that shows audit days for Stage 1, Stage 2 and surveillance, along with on-site and remote components and any multi-site efficiencies.

How do we maintain ISO certification compliance in Württemberg over time?

Maintain your certification by running scheduled internal audits, closing nonconformities, holding management reviews and completing surveillance and recertification audits on time, with support available from Pacific Certifications where needed.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs