Introduction

South Africa’s economy is driven by mining and minerals, automotive and machinery, food processing, textiles, chemicals, construction and engineering, logistics and ports, tourism, finance and a large services and public sector. Services now account for more than sixty percent of GDP with industry around a quarter and agriculture a small but strategic share.

ISO 9001 for quality, ISO 14001 for environment and ISO 45001 for occupational health and safety help South African organisations keep works and service quality steady, control impacts and answer buyer due-diligence in regional and global markets.

Share your scope and sites in South Africa with Pacific Certifications and we will map accreditation coverage, recommended audit days and Stage-1 and Stage-2 windows that match your project cycles and seasons.

Economic context and industry overview

Recent assessments show growth below one percent a year on average, with projections near one percent for 2025 as structural constraints slowly ease and financial services lead expansion. Mining, manufacturing and services still form a diversified base yet face power limits, logistics bottlenecks, skills gaps and weaker external demand.

These conditions keep attention on energy use, asset care, safety culture, data handling and logistics reliability, areas where ISO management systems give a structured way to show control.

Why ISO certifications matter in South Africa?

Local and international buyers, lenders and regulators expect clear systems and traceable records, especially in mining and heavy industry, automotive and engineering, logistics and ports, construction and energy, healthcare and labs, banking and digital services. ISO management systems help organisations move faster through vendor checks, keep worksites and service lines steady, reduce incidents and protect data and uptime.

ISO 9001 supports process control and supplier oversight in mines, plants, workshops, fleet operations and service contracts, ISO 14001 and ISO 45001 support EHS discipline on shafts, open-pits, factories, terminals, depots and project sites, ISO 50001 supports energy-management in power-intensive users as tariffs and decarbonisation pressure rise.

Popular ISO standards in South Africa

| Industry focus | Commonly requested standards | Why they matter |

| Mining, smelting, metals and minerals | ISO 9001, ISO 14001, ISO 45001, ISO 50001, ISO 22301 | Grade and delivery quality, EHS, energy use and continuity |

| Automotive, machinery and components | ISO 9001, IATF 16949, ISO 14001, ISO 45001 | Product quality, line stability and safety on shop-floors and test bays |

| Ports, terminals, warehousing and 3PL | ISO 9001, ISO 14001, ISO 45001, ISO 28000, ISO 22301 | Turnaround discipline, yard safety, chain security and continuity |

| Construction, EPC, energy and utilities | ISO 9001, ISO 14001, ISO 45001, ISO 50001, ISO 22301 | Works quality, site EHS, energy performance and service continuity |

| Food, beverage, agribusiness and retail | ISO 9001, ISO 22000, ISO 14001 | Service consistency, HACCP, hygiene and environmental care |

Certification process in South Africa

Preparation starts with a clear view of how work runs today and how evidence is stored across sites, divisions and partners. The aim is to make your system auditable without breaking day-to-day routines. Steps to consider:

- List products or services, sites, headcount and high-risk processes for a clear scope

- Map processes end-to-end so handoffs, records and responsibilities are visible

- Set policy and measurable objectives linked to customer, lender and legal needs

- Build evidence packs for operations, maintenance, labs, IT, HSE, logistics, procurement and finance

- Train process owners and keep competence matrices and attendance records current

- Blend on-site checks with remote interviews and file-reviews where suitable to cut travel time

- Keep permits, licences, inspection reports and regulator and lender correspondence organised for quick verification

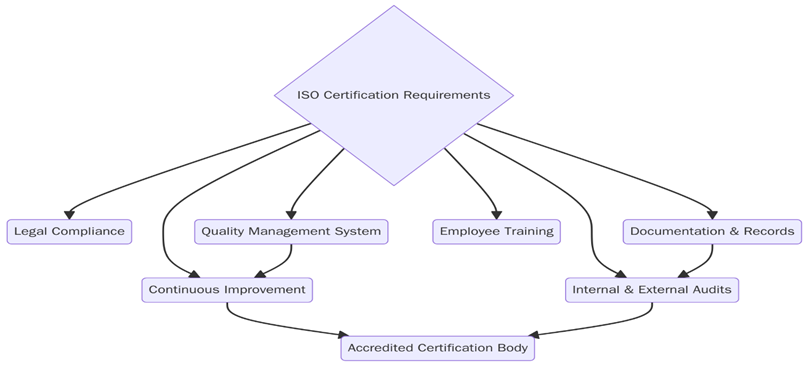

What are the requirements of ISO certifications in South Africa?

Implementation should mirror real work in shafts and plants, rail and road yards, ports and depots, project sites, clinics and labs, offices and data rooms so records hold up in audits, inspections and buyer visits. Key requirements include:

- Scope aligned to products or services, processes and sites including projects, mobile teams and multi-site programmes

- Controlled documents and records that match practice, with version-control and clear access rules for plant, branch and head-office teams

- Risk assessment with operational controls for real hazards such as mine safety, lifting and transport, HACCP, environmental aspects, privacy or security, energy and change-management

- Competence matrices and training records for process owners and high-risk roles in operations, maintenance, driving, lifting, HSE, IT and quality

- Internal audits with reports, non-conformities, root-cause analysis and verified closures across sites, contractors and key suppliers

Tip: align controls with local laws, industry codes, lender terms and major-customer requirements so that audits, vendor checks and site visits follow a predictable path.

What are the benefits of ISO certifications in South Africa?

Use certification to move faster through tenders, supplier onboarding and lender reviews, reassure customers and partners and keep work steady through demand swings, power issues and project cycles. Main benefits include:

- Faster pre-qualification in buyer portals and public procurement for mining, industry, construction, logistics and services

- Fewer incidents, defects and stoppages on lines, shafts, ports, depots and care units which cuts re-work and disruption

- Clear roles and skill paths for operations, drivers, mechanics, technicians, HSE, lab and back-office teams which supports handover and cover

- Traceable data for investigations, warranty claims, ESG reports and transaction or lender due-diligence

Market Trends

Country and sector outlooks point to low but positive growth, with financial services and trade providing support while power limits, logistics constraints and high unemployment keep pressure on firms. At the same time energy reform and just-transition projects aim to repower ageing coal assets, open the grid to more private generation and scale renewables and storage.

OEMs, traders, lenders and rating agencies are asking more detailed questions on safety performance, tailings and emission control, port and warehouse reliability, cyber-security, data protection and business continuity in South African operations. This is driving demand for integrated ISO 9001, ISO 14001 and ISO 45001 in plants and projects, ISO 50001 in energy-intensive sites, ISO/IEC 27001 and ISO 22301 in banks and shared-service centres and ISO 22000 in food and retail, so that teams can answer questionnaires and site visits with structured evidence rather than ad-hoc files.

Challenges faced in South Africa

Expectations on quality, safety, environment, social impact and data are rising while many organisations still face power cuts, port delays, cost pressure and skills gaps. Typical pain points include:

- Budgeting time and funds for certification and system upkeep when margins are tight

- Seeing ISO as paperwork in some teams which slows adoption and daily use

- Shortage of trained internal auditors in smaller firms or remote towns

- Gaps in document-control, internal audits, corrective-action follow-up and record-keeping across sites

What is the cost of certification in South Africa?

Budgets are confirmed after scoping and reflect headcount and risk, the number and spread of sites, your standards set, whether the programme is single or integrated such as 9001 plus 14001 plus 45001 or 9001 plus 22000, sampling depth for mines, plants, ports, warehouses, clinics, hotels or branches and any field-logistics for remote or higher-risk locations.

For a personalised quote, contact support@pacificcert.com.

What is the timeline for certification in South Africa?

Timelines depend on document and record readiness, the speed of closing Stage-1 findings, single versus multi-site scope and whether the programme is single-standard or integrated. Planning around shutdowns, turnaround seasons, mining campaigns, construction windows, retail peaks or public-sector calendars also affects duration.

A prepared single site such as one mine, plant, terminal, office or hospital can often move from application to decision within one audit cycle. Multi-site or integrated programmes need extra sampling and planning time, especially where several provinces, group entities, partners or franchise locations are in scope.

Important standards often requested by buyers in South Africa

| Standard | Typical drivers in South Africa |

| ISO 9001 | Pre-qualification for miners, OEMs, tier-suppliers, logistics and public contracts |

| ISO 14001 and ISO 45001 | Environmental and safety control for mining, industry, construction and yards |

| ISO 22000 | HACCP and traceability for food and beverage, agribusiness, hospitality and retail |

| ISO/IEC 27001 and ISO 22301 | Security and continuity for banks, fintech, telecom and shared-service centres |

| ISO 50001 | Energy performance for utilities, industrial users and large buildings |

How Pacific Certifications can help?

Pacific Certifications audits and certifies ISO management systems for mining and minerals, automotive and engineering, ports and logistics, construction and energy, agrifood and retail, healthcare and labs, banks and fintech and ICT or cloud providers across South Africa. We work under recognised accreditation with transparent pricing and a team used to site realities, power and logistics limits and buyer expectations across African and global supply chains. Our certificates are accepted by procurement portals and international customers and we are recognised by ABIS.

Request your ISO audit plan and fee estimate. We will help you map Stage-1 and Stage-2 timelines and evidence needs for your organisation. Contact us at support@pacificcert.com or visit www.pacificcert.com.

Accredited training programs

Pacific Certifications provides accredited training programmes in South Africa for ISO 9001, ISO 14001, ISO 45001, ISO 22000, ISO/IEC 27001, ISO 22301 and ISO/IEC 20000-1.

- Lead Auditor Training: for professionals who audit these systems in mines, plants, terminals, hospitals, banks and digital platforms

- Lead Implementer Training: for personnel who build or improve systems in contractors, logistics networks, clinics, utilities, NGOs, projects and ICT

These programmes run online or on-site depending on client needs under ISO/IEC 17024 for personnel certification.

To begin the process or request a quotation, contact us at support@pacificcert.com or visit www.pacificcert.com.

FAQs

How long does certification take in South Africa?

Often one audit cycle for a prepared single site, longer for multi-site or integrated scope.

What mainly decides audit time?

Headcount, risk-level, number of sites, chosen standards and on-site versus remote-audit mix.

Can audits be partly remote?

Yes, many interviews and record-checks can be remote with focused on-site visits for higher-risk work.

Which standards suit mining and metals?

Usually ISO 9001, ISO 14001 and ISO 45001, with ISO 50001 and ISO 22301 where energy and continuity are key.

What fits ports, terminals and 3PLs?

ISO 9001, ISO 14001, ISO 45001 and often ISO 28000 and ISO 22301 for chain security and continuity.

Which standards are most used by food and retail?

ISO 9001 and ISO 22000 with ISO 14001 where environmental impact is in scope.

Do you work with SMEs and local contractors?

Yes, audit time and sampling are right-sized while keeping accreditation rules intact.

What should we prepare before Stage-1?

Scope, process map, risk records, policy, objectives, competence records and recent internal-audit and management-review results.

Are certificates accepted by international buyers and lenders?

Accredited certificates are widely accepted, subject to each buyer or lender’s normal checks.

How do we maintain certification each year?

Keep internal audits on schedule, close non-conformities, hold management reviews, monitor KPIs and complete surveillance and recertification on time.

Ready to get ISO certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs