What is ISO 13623:2017?

ISO 13623:2017 is an international standard that provides guidelines for the design, construction, operation, and maintenance of pipeline transportation systems used in the petroleum and natural gas industries. The standard establishes the safety, operational and environmental requirements that pipeline operators must adhere to in order to ensure the integrity, reliability and efficiency of pipeline systems. It applies to both onshore and offshore pipelines, including those used for transporting crude oil, natural gas, refined products and other related substances.

The purpose of ISO 13623 is to improve safety and environmental performance while also providing a framework for the consistent implementation of pipeline systems across different sectors within the petroleum and natural gas industries. The standard is intended to minimize risks related to pipeline failures, spills, leaks and other operational hazards.

For more information contact us at support@pacificcert.com.

Purpose of ISO 13623

This standard provides essential safety guidelines for pipeline design, construction, and operation, as well as recommendations for maintenance, inspection and integrity management.

It addresses all stages of the pipeline lifecycle, from planning and design to operation and decommissioning, and aims to improve the sustainability and resilience of pipeline infrastructure.

Scope and Applicability

ISO 13623 applies to the design, construction, operation, and maintenance of pipeline transportation systems in the petroleum and natural gas industries, including systems for transporting raw and processed materials. The standard is relevant to organizations involved in the pipeline design and construction, pipeline operators, service providers, and maintenance companies.

The standard is applicable to both onshore and offshore pipelines, covering all phases of pipeline operation, from installation and commissioning to routine maintenance and integrity management. It ensures that pipelines are designed to operate smoothly and safely, with appropriate risk management measures in place to handle issues like pressure fluctuations, corrosion, and operational challenges.

ISO 13623 is critical for organizations seeking to comply with regulatory and environmental requirements in the oil and gas sector and is integral to maintaining pipeline systems that meet international safety and performance standards.

Key Definitions

- Pipeline Transportation System: A system of pipes, valves, and related infrastructure used to transport oil, gas, or other materials from one location to another.

- Integrity Management: A process that ensures the pipeline is maintained, monitored, and inspected to ensure its safe and reliable operation throughout its lifecycle.

- Corrosion Control: Measures to prevent or reduce the deterioration of pipeline material due to chemical reactions with its environment.

- Pressure Testing: The process of pressurizing a pipeline system to verify its strength and integrity.

- Decommissioning: The final phase of a pipeline’s lifecycle, involving the shutdown, removal, or abandonment of the pipeline when it is no longer in use.

Clause-wise structure of ISO 13623

ISO 13623 is structured into several clauses, each focusing on specific elements of pipeline transportation system design, operation, and maintenance. Below is the clause-wise breakdown:

Clause Number | Title |

| Description |

Clause 1 | Scope | Defines the scope of the standard, specifying the types of pipelines and transportation systems covered by the guidelines. | |

Clause 2 | Normative References | Lists other standards and documents referenced in ISO 13623 to ensure overreaching compliance. | |

Clause 3 | Terms and Definitions | Provides definitions for key terms used throughout the standard to ensure clarity and consistency. | |

Clause 4 | General Requirements | Outlines the fundamental requirements for pipeline design, construction, and operation to ensure safety and compliance. | |

Clause 5 | Design and Construction | Covers the principles and guidelines for designing and constructing pipelines, including material selection, pressure specifications, and safety measures. | |

Clause 6 | Operation and Maintenance | Specifies the operational and maintenance procedures that must be followed to ensure the safety and integrity of the pipeline system. | |

Clause 7 | Monitoring and Surveillance | Outlines the requirements for monitoring pipeline systems to detect and respond to issues such as leaks, corrosion, and pressure variations. | |

Clause 8 | Emergency Response and Incident Management | Details the processes and procedures for responding to pipeline incidents, including spills and leaks, to minimize environmental and safety risks. |

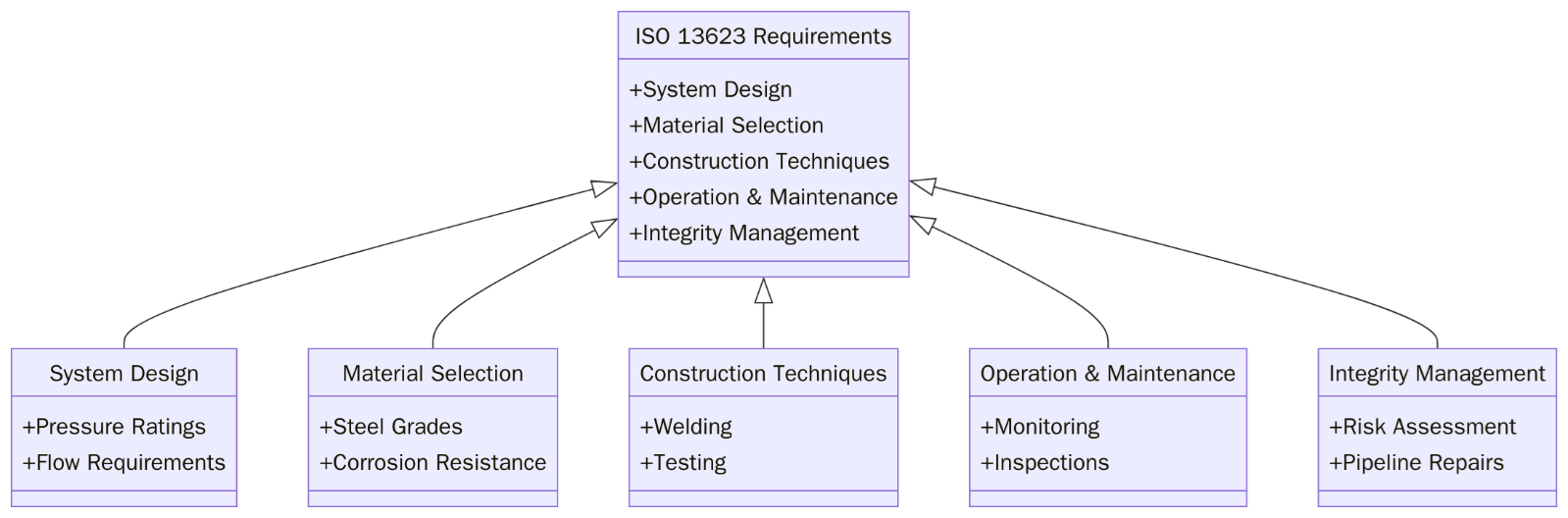

What are the requirements of ISO 13623?

To ensure pipeline systems are safe, reliable, and compliant with industry standards, ISO 13623 outlines several key requirements. Below are the essential requirements for compliance with the standard:

- Design pipelines to meet operational requirements, ensuring the right materials are selected based on environmental and operational conditions.

- Maintain pipelines within defined pressure and temperature limits to prevent damage and ensure safe operation.

- Implement effective measures to control corrosion, including coating, cathodic protection and regular inspections.

- Regularly monitor pipeline integrity and conduct routine inspections to detect leaks, corrosion, or other defects.

- Develop and maintain a overreaching emergency response plan to address potential pipeline incidents, including spills and leaks.

- Establish protocols to minimize the environmental impact of pipeline operations and address any potential contamination risks.

- Maintain proper documentation of pipeline design, operation, maintenance, and inspection activities to ensure traceability and compliance with regulatory requirements.

For more information, contact us at support@pacificcert.com.

Audit Checklist

The audit checklist for ISO 13623 typically includes the following elements:

- Have cloud roles and responsibilities between the provider and customer been clearly defined and documented?

- Is virtual machine configuration securely managed and isolated in multi-tenant cloud environments?

- Are procedures in place for the secure return, deletion, or migration of customer assets after contract termination?

- Is administrative access by cloud service customers properly controlled and monitored by the provider?

- Are cloud-specific security requirements addressed in the service agreement (data location, jurisdiction etc.)?

- Is customer activity within the cloud environment logged, monitored, and reviewed for anomalies?

- Are customers informed of any changes that may affect cloud service security controls or SLAs?

- Are measures implemented to segregate and protect customer data in shared infrastructure setups?

- Is there a documented process for handling cloud-specific incidents and notifying affected parties?

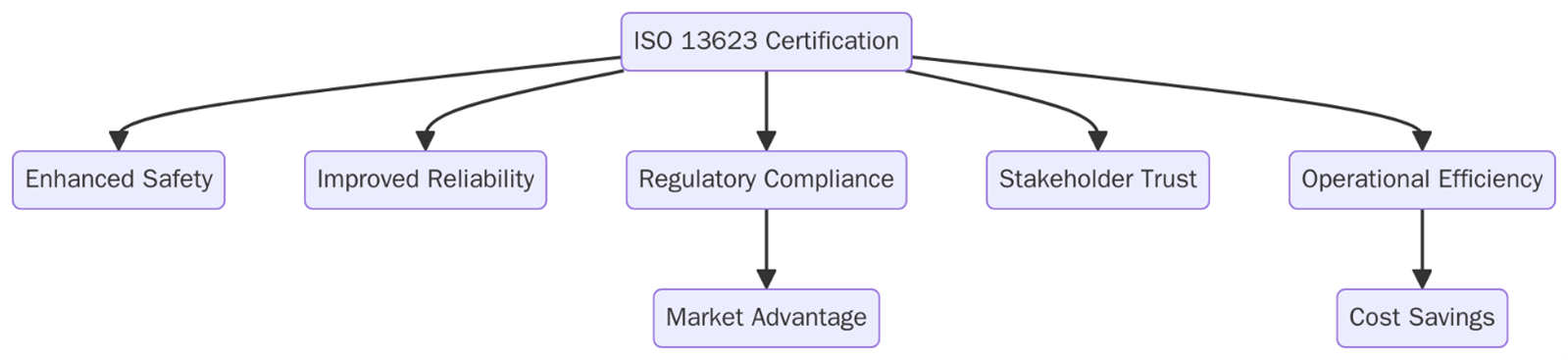

What are the benefits of ISO 13623 Certification?

ISO 13623 certification brings several key benefits to organizations involved in the pipeline transportation of petroleum and natural gas. Below are some of the main benefits:

- Certification ensures that pipelines are designed, constructed, and maintained according to stringent safety standards, minimizing the risk of accidents and environmental damage.

- By adhering to the standard’s guidelines, organizations can optimize pipeline performance and reduce operational downtime due to maintenance or safety issues.

- ISO 13623 certification helps organizations meet local and international regulations related to pipeline safety, operation, and environmental protection.

- By following the environmental guidelines in ISO 13623, organizations can reduce their environmental impact, ensuring that their operations are more sustainable.

- Achieving certification can improve the organization’s reputation, demonstrating a commitment to safety, quality, and environmental stewardship.

There has been a growing trend of incorporating smart sensors and IoT-based monitoring systems into pipeline operations to improve real-time monitoring and early detection of potential failures. Many pipeline operators are also adopting AI-driven predictive maintenance systems to reduce downtime and improve the reliability of pipelines.

In the recent years, we expect the energy and infrastructure sectors to place heightened importance on maintaining pipeline safety and integrity, driving broader adoption of ISO 13623 in pipeline projects worldwide.

Certification Process

The certification process involves the following stages:

- Pre-Certification Assessment: Conduct an internal review to assess the organization’s readiness and identify areas for improvement.

- Documentation Review: Review the pipeline design, construction, and operational documentation to ensure compliance with ISO 13623.

- Stage 1 Audit: Conduct an initial audit to assess the organization’s pipeline safety and compliance processes.

- Stage 2 Audit: Perform an on-site audit to evaluate the implementation of safety and operational controls in the pipeline.

- Certification Awarded: Upon successful audit, the organization will receive certification for ISO 13623.

- Ongoing Monitoring: Regular audits and reviews are required to maintain certification and ensure continued compliance.

Timeline for ISO 13623 Certification

The timeline for certification involves several phases. Preparation takes1-2 months for assessment, documentation gathering, and implementation of security measures. Audit takes another 1-2 months for the auditing process. Certification usually happens in 1 month after the audit. Ongoing Surveillance are the Annual audits to ensure continued compliance

What is the cost of ISO 13623 Certification?

The cost of ISO 13623 certification varies based on factors such as the size of the pipeline system, its complexity, and the number of facilities involved. Costs include Audit Fee which is the Fee for the certification body’s audit process. Training costs are the costs for educating staff on GDP Certification and the necessary processes for compliance. Ongoing maintenance are the costs for regular audits and recertification required every 3 years.

How Pacific Certifications Can Help?

At Pacific Certifications, we provide overreaching auditing and certification services for ISO 13623. Our team will guide you through the entire certification process, ensuring your pipeline systems meet all safety, regulatory, and environmental standards. Our services include:

- Stage 1 and Stage 2 audits to evaluate pipeline systems and ensure compliance.

- Objective conformity assessments based on ISO 13623.

- Certification issuance after successful audits.

- Ongoing surveillance audits to ensure continued compliance with the standard.

For audits and certification, contact support@pacificcert.com.

ISO 9001 and ISO 13623 Training and Courses

Various training courses are available to help organizations comply with ISO 13623, including:

- Lead Auditor Training – Equips professionals to conduct external third-party audits.

- Lead Implementer Training – For those responsible for planning and executing ISO 13623implementation.

- Internal Auditor Training – Preparing internal auditors for certification audits

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 13623 training, our team is equipped to help you. Contact us at support@pacificcert.com.

Frequently Asked Questions (FAQs)

How long does it take to get ISO 13623 certification?

The certification process typically takes 3-6 months, depending on your organization’s preparedness and audit outcomes.

Is ISO 13623 certification mandatory for all pipeline operators?

While ISO 13623 certification is not mandatory, it is highly recommended for organizations seeking to ensure pipeline safety, reliability, and environmental compliance.

What are the main benefits of ISO 13623 certification?

Certification improves pipeline safety, operational efficiency, and environmental protection, and improves compliance with global regulations.

Can I apply for ISO 13623 certification without an existing safety management system?

No, a formal safety management system must be in place before applying for certification.

How often do I need to renew ISO 13623 certification?

ISO 13623 certification is valid for three years, after which recertification is required.

Ready to get ISO 13623 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs