ISO Certifications for Steel Pipe and Tube Manufacturing Businesses, Requirements and Benefits

The steel pipe and tube manufacturing industry is a cornerstone of modern infrastructure, enabling innovations across sectors like construction and transportation.

ISO standards are globally recognized benchmarks for quality, safety, and efficiency. In steel pipe and tube manufacturing, these standards ensure that products meet stringent requirements for durability, environmental compliance, and functionality.

The steel industry operates in a dynamic environment, with advancements in production techniques and the need for sustainable practices driving the adoption of ISO standards. From ensuring material integrity to compliance with regulatory norms, these certifications lay the foundation for trust and reliability.

By securing ISO certifications, manufacturers can demonstrate their commitment to excellence and gain a competitive edge in both domestic and international markets.

Reach out directly at support@pacificcert.com to get personalized guidance and start your ISO certification process.

Applicable ISO Standards for Steel Pipe and Tube Manufacturing

Various ISO standards cater to the diverse needs of the steel pipe and tube industry, addressing aspects like quality management, environmental responsibility, and occupational safety. Some of the most relevant certifications include:

ISO 9001: Quality Management System (QMS): This standard focuses on establishing a robust quality management system to ensure consistent product quality. ISO 9001 is vital for steel manufacturers to meet customer expectations and enhance operational efficiency.

ISO 14001: Environmental Management System (EMS): Steel production can have significant environmental impacts. ISO 14001 provides a framework to manage and mitigate environmental risks, enabling manufacturers to align with global sustainability goals.

ISO 45001: Occupational Health and Safety Management System: Workplace safety is paramount in steel manufacturing. ISO 45001 addresses the health and safety of workers, reducing workplace hazards and promoting a safe environment.

ISO 50001: Energy Management System: Energy-intensive processes are common in steel manufacturing. ISO 50001 offers guidelines for improving energy efficiency, reducing costs, and supporting environmental initiatives.

ISO 27001: Information Security Management System: While not directly linked to manufacturing, ISO 27001 is essential for securing sensitive business and operational data in an era of increasing cybersecurity threats.

ISO 3834: Quality Requirements for Welding: Given the critical role of welding in steel pipe production, ISO 3834 ensures that welding practices meet stringent quality standards.

ISO 15156: Materials for Use in H2S Environments: This standard specifies materials suitable for sour gas environments, a critical factor in industries like oil and gas where steel pipes are extensively used.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in auditing and certifying businesses for compliance with applicable ISO standards. With extensive experience in steel pipe and tube manufacturing, our team ensures a seamless certification process, empowering your organization to achieve international recognition.

Our services include:

- Comprehensive audits to assess your readiness for ISO certification.

- Clear and precise communication throughout the certification journey.

- A commitment to impartiality and confidentiality.

With a global footprint and a reputation for excellence, Pacific Certifications is your trusted partner for achieving ISO compliance.

Requirements of ISO Certifications for Steel Pipe and Tube Manufacturing

Implementing ISO standards requires manufacturers to meet specific criteria tailored to the industry. Here are some key requirements for common ISO certifications:

ISO 9001: Quality Management System (QMS)

ISO 9001 focuses on ensuring consistent quality in production and customer satisfaction. Here are its specific requirements:

- Quality Policy and Objectives: Define a quality policy aligned with organizational goals and customer expectations.

- Documentation: Maintain a structured Quality Management System (QMS) documentation, including a manual, policies, and procedures.

- Process Control: Establish clear guidelines for monitoring and controlling production processes to meet specifications.

- Customer Focus: Address customer needs and expectations to enhance satisfaction.

- Continuous Improvement: Use tools like internal audits and management reviews to identify and address areas for improvement.

ISO 14001: Environmental Management System (EMS)

ISO 14001 is designed to manage environmental impacts effectively. Its requirements include:

- Environmental Policy: Create and maintain an environmental policy focused on sustainable practices.

- Environmental Aspects and Impacts: Identify how your operations interact with the environment and assess the potential impacts.

- Compliance Obligations: Ensure adherence to local and international environmental laws and regulations.

- Operational Controls: Implement controls to manage waste, emissions, and resource usage.

- Monitoring and Measurement: Continuously track environmental performance and set measurable improvement goals.

ISO 45001: Occupational Health and Safety Management System (OHSMS)

ISO 45001 prioritizes workplace safety and the health of employees. Key requirements include:

- Hazard Identification and Risk Assessment: Identify potential risks and hazards in manufacturing processes and implement preventive measures.

- Worker Participation: Engage employees in safety initiatives and decision-making processes.

- Emergency Preparedness: Develop plans for responding to emergencies like fire, accidents, or chemical spills.

- Compliance with Legal Requirements: Ensure compliance with health and safety laws and industry regulations.

- Incident Investigation: Record and analyze incidents to prevent recurrence.

ISO 50001: Energy Management System (EnMS)

ISO 50001 aims to enhance energy efficiency and reduce consumption. Its core requirements are:

- Energy Review: Conduct an energy review to evaluate current energy usage and identify significant energy-consuming areas.

- Energy Policy: Develop a policy that outlines objectives and goals for energy performance improvements.

- Baseline Establishment: Define an energy baseline to track and measure progress.

- Action Plans: Implement energy-saving measures and monitor their effectiveness.

- Performance Measurement: Use data and metrics to evaluate energy efficiency improvements.

ISO 3834: Quality Requirements for Welding

Welding is a critical process in steel pipe and tube production, and ISO 3834 ensures its reliability. Requirements include:

- Welding Procedures: Establish and document welding procedures that comply with recognized standards.

- Welder Qualification: Ensure welders are trained and certified according to the required competencies.

- Inspection and Testing: Perform thorough inspections and tests to validate welding quality.

- Material Traceability: Maintain records of materials used in welding processes.

- Non-Conformance Management: Implement a system to identify and address defects or deviations in welding.

ISO 27001: Information Security Management System (ISMS)

Although not specific to manufacturing, ISO 27001 is essential for protecting sensitive business information. Requirements include:

- Risk Assessment: Identify and assess risks to information security.

- Access Control: Restrict access to critical data to authorized personnel only.

- Incident Management: Create protocols for responding to and mitigating data breaches.

- Policy Development: Define an information security policy to guide all related activities.

ISO 15156: Materials for Use in H2S Environments

This standard addresses the durability of materials used in environments with hydrogen sulfide (H2S). Key requirements include:

- Material Selection: Choose materials that resist corrosion and stress cracking caused by H2S exposure.

- Testing Procedures: Perform rigorous testing to validate material performance under sour service conditions.

- Documentation: Maintain detailed records of material specifications and performance evaluations.

These detailed requirements help steel pipe and tube manufacturers align their operations with global standards, ensuring superior product quality, safety, and sustainability. Each standard can significantly enhance different aspects of production, contributing to long-term success and market leadership.

Send an email to support@pacificcert.com for a step-by-step overview of how we’ll assist with your ISO certification needs.

Benefits of ISO Certifications for Steel Pipe and Tube Manufacturing

Adopting ISO certifications can transform your manufacturing processes, yielding numerous advantages:

Improved Product Quality: ISO certifications emphasize quality control at every production stage, ensuring superior products that meet customer expectations.

Enhanced Market Competitiveness: Compliance with international standards enables access to global markets, building trust among clients and stakeholders.

Operational Efficiency: ISO standards promote streamlined processes, reducing waste and lowering production costs.

Regulatory Compliance: Certifications like ISO 14001 and ISO 45001 ensure adherence to environmental and safety regulations, mitigating legal risks.

Customer Satisfaction: Consistent quality and commitment to sustainability resonate with customers, fostering long-term loyalty.

In 2024, the steel industry faces exciting opportunities driven by technological advancements and a focus on sustainability. According to industry reports, demand for lightweight, high-strength pipes is growing, particularly in renewable energy projects. Additionally, there’s a significant push toward digitization, with smart factories incorporating ISO standards to enhance productivity.

Manufacturers embracing ISO 50001 for energy efficiency are also better positioned to meet global climate commitments, further strengthening their market standing.

Are you ready to elevate your steel pipe and tube manufacturing business with ISO certifications? Partner with Pacific Certifications and achieve compliance with globally recognized standards.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Steel Pipe and Tube Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Steel Pipe and Tube Manufacturing

ISO certifications are international standards that ensure quality, safety, and efficiency in manufacturing. For steel manufacturers, they provide a competitive edge and enhance customer trust.

ISO 9001 improves quality management, ensuring consistent production standards and customer satisfaction while streamlining operations.

While not mandatory, ISO 14001 is highly recommended as it helps manage environmental impacts and demonstrates sustainability efforts.

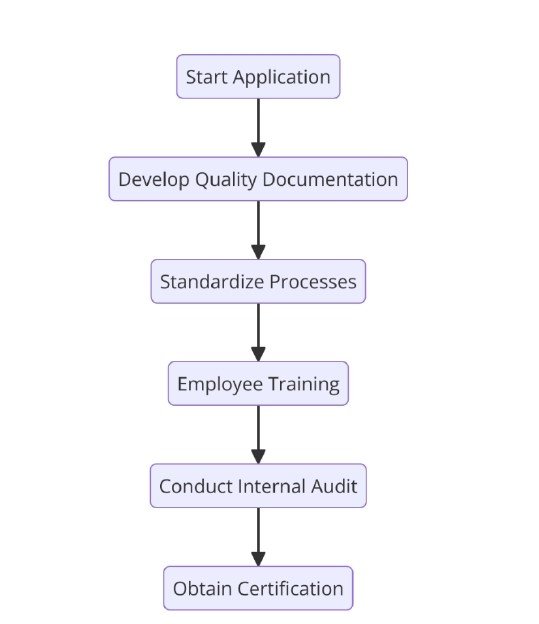

The process includes an initial audit, identification of gaps, implementation of necessary changes, and a final certification audit conducted by a certification body like Pacific Certifications.

Pacific Certifications offers impartial and reliable auditing services with expertise in the steel manufacturing sector, ensuring a smooth certification process.

Yes, ISO certifications are universally accepted, making them essential for businesses aiming to compete in international markets.

Read More at: Blogs by Pacific Certifications