ISO Certifications for Railway Equipment Manufacturing and Repair Businesses, Requirements and Benefits

The railway industry plays a crucial role in global transportation, with equipment manufacturing and repair forming its backbone. Adherence to stringent quality, and environmental standards is vital to ensuring the reliability and efficiency of railway systems. This is where ISO certifications for railway equipment manufacturing and repair emerge as a cornerstone, enabling businesses to meet international benchmarks and gain a competitive edge.

ISO standards are internationally recognized frameworks designed to ensure consistency, safety, and quality across industries. For the railway sector, they provide guidelines that encompass everything from equipment design and manufacturing to repair and maintenance practices.

The railway sector, known for its stringent safety requirements, relies on ISO certifications to enhance operational efficiency and ensure compliance with global standards. These certifications address the technical, environmental, and operational challenges faced by railway equipment manufacturers and repair units.

With governments and private organizations investing heavily in modernizing railway infrastructure in 2024, adopting ISO standards is no longer optional but a necessity for market survival and growth.

If you’re seeking ISO certification for railway equipment manufacturing and repair, we’re here to help. Contact us at support@pacificcert.com or call +91-8595603096 to get started today.

Applicable ISO Standards for Railway Equipment Manufacturing and Repair

Several ISO standards cater specifically to the railway industry. Here are the most relevant ones:

- ISO 9001: Quality Management Systems (QMS): ISO 9001 focuses on establishing a robust quality management system to ensure consistent product quality. For railway equipment manufacturers, this means improved processes for design, production, and repair while meeting customer expectations and regulatory requirements.

- ISO 14001: Environmental Management Systems (EMS): Environmental sustainability is critical in today’s manufacturing world. ISO 14001 helps railway equipment manufacturers and repair companies minimize their environmental impact through efficient resource management and waste reduction.

- ISO/TS 22163: Railway Quality Management Systems: Developed explicitly for the railway sector, this standard builds on ISO 9001, addressing the unique requirements of railway equipment production and repair. It includes supplier management, safety assessments, and lifecycle management of railway products.

- ISO 45001: Occupational Health and Safety Management Systems: Railway equipment manufacturing involves complex machinery and potentially hazardous processes. ISO 45001 ensures workplace safety, reducing the risk of accidents and fostering a healthy working environment.

- ISO 50001: Energy Management Systems: This standard guides organizations in optimizing energy use, a crucial aspect of sustainable manufacturing in the railway industry. By implementing ISO 50001, companies can significantly cut energy costs and reduce their carbon footprint.

- ISO 27001: Information Security Management Systems (ISMS): With increasing reliance on digital technologies in manufacturing, ISO 27001 ensures data security in sensitive areas, including design, production scheduling, and supplier communications.

- ISO 55001: Asset Management: For companies managing vast fleets of railway equipment, ISO 55001 offers a framework for asset optimization, ensuring maximum efficiency and reducing operational costs.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing comprehensive audit and certification services tailored to the railway equipment manufacturing and repair industry. With a reputation for excellence and impartiality, we guide organizations through the certification process, ensuring compliance with the applicable ISO standards.

We understand the unique challenges of the railway sector and offer efficient and transparent certification services to help businesses enhance quality, safety, and sustainability. Our services are trusted globally, ensuring you meet the industry’s highest benchmarks.

Ready to gain a competitive edge in the railway sector? Contact Pacific Certifications for ISO certification at support@pacificcert.com or +91-8595603096.

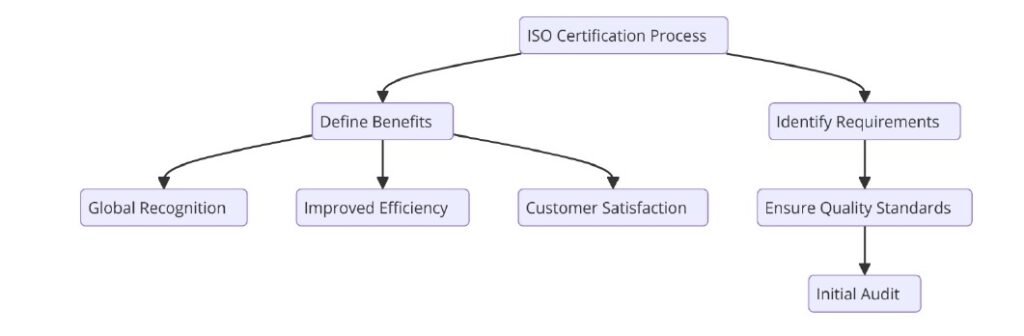

Requirements of ISO Certifications for Railway Equipment Manufacturing and Repair

Each ISO standard applicable to the railway equipment manufacturing and repair industry has specific requirements. Here’s a breakdown for a clearer understanding:

ISO 9001: Quality Management Systems (QMS)

ISO 9001 focuses on quality management and continuous improvement. Key requirements include:

- Documented Quality Policy: Organizations must define a quality policy aligned with their strategic goals.

- Customer Focus: Processes must prioritize customer satisfaction and needs.

- Process Approach: Clear documentation and management of all operational processes.

- Risk-Based Thinking: Identification and mitigation of risks that may impact quality.

- Internal Audits: Regular internal reviews to ensure the system’s effectiveness.

- Corrective Actions: A system to address and rectify non-conformities.

ISO 14001: Environmental Management Systems (EMS)

This standard requires organizations to manage environmental impacts effectively. Requirements include:

- Environmental Policy: A formal policy committing to pollution prevention and compliance with legal requirements.

- Environmental Impact Assessment: Regular evaluations of how operations affect the environment.

- Legal Compliance: Adherence to applicable environmental laws and regulations.

- Resource Optimization: Efficient use of raw materials, water, and energy.

- Waste Management: Systems for reducing, reusing, and recycling waste.

- Monitoring and Measurement: Continuous tracking of environmental performance.

ISO/TS 22163: Railway Quality Management Systems

ISO/TS 22163 builds on ISO 9001, adding railway-specific requirements. Key aspects include:

- Safety Management: Processes to assess and manage safety risks associated with railway equipment.

- Lifecycle Management: Integration of lifecycle considerations in the design, manufacturing, and repair stages.

- Supplier Management: Robust procedures for supplier evaluation and monitoring.

- Reliability and Availability: Ensuring equipment meets performance benchmarks for reliability and availability.

- Configuration Management: Controlling changes in product design to maintain consistency.

ISO 45001: Occupational Health and Safety Management Systems

ISO 45001 ensures safe and healthy work environments. Core requirements are:

- Hazard Identification: Systematic identification of workplace hazards.

- Risk Management: Implementation of controls to reduce safety risks.

- Worker Participation: Involvement of employees in health and safety decision-making.

- Emergency Preparedness: Clear plans for dealing with emergencies and incidents.

- Health Monitoring: Regular health check-ups and monitoring for employees.

- Training and Awareness: Education for staff on safety practices and procedures.

ISO 50001: Energy Management Systems (EnMS)

ISO 50001 promotes efficient energy use. Its key requirements include:

- Energy Policy: A documented commitment to energy efficiency and conservation.

- Energy Review: Evaluation of current energy use and identification of areas for improvement.

- Energy Performance Indicators (EnPIs): Metrics to measure energy efficiency progress.

- Action Plan: Specific initiatives to improve energy performance.

- Monitoring and Reporting: Regular analysis and reporting of energy data.

ISO 27001: Information Security Management Systems (ISMS)

ISO 27001 protects sensitive information used in railway manufacturing. Key requirements include:

- Information Security Policy: Establishment of a framework for securing data.

- Risk Assessment: Identification of information-related risks and implementation of controls.

- Access Control: Limiting access to sensitive information based on roles.

- Incident Management: Procedures to handle data breaches or security incidents.

- Auditing and Monitoring: Continuous monitoring of information security practices.

ISO 55001: Asset Management Systems

For managing railway assets effectively, ISO 55001 requires:

- Asset Management Policy: A strategy for maintaining and optimizing assets.

- Lifecycle Considerations: Integration of asset lifecycle management in planning.

- Risk Management: Identification and control of risks associated with asset performance.

- Performance Monitoring: Regular evaluation of asset performance against objectives.

- Improvement Plan: Continuous refinement of asset management practices.

Let us guide you through the ISO certification process for railway equipment manufacturing and repair. Email us at support@pacificcert.com or call +91-8595603096 for assistance.

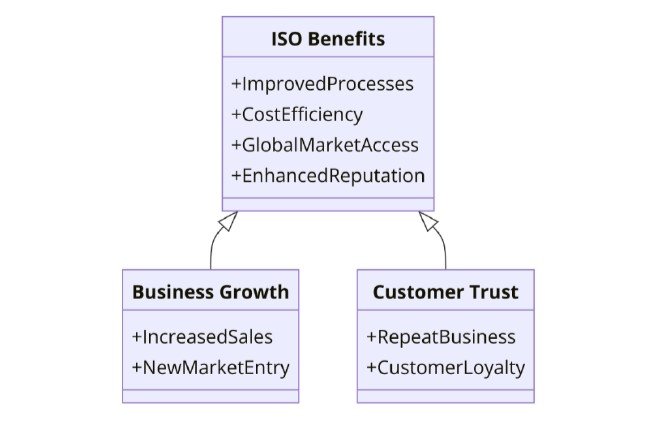

Benefits of ISO Certifications for Railway Equipment Manufacturing and Repair

Achieving ISO certification brings a host of advantages to businesses in the railway sector:

Enhanced Quality and Reliability: ISO standards ensure the consistent production of high-quality equipment, improving reliability and customer satisfaction.

Market Competitiveness: Certified organizations gain a competitive edge, especially in international markets where ISO certifications are often prerequisites for contracts.

Operational Efficiency: Standardized processes reduce waste, optimize resource utilization, and streamline operations, boosting overall productivity.

Improved Safety Standards: Adopting ISO 45001 significantly reduces workplace hazards, creating a safer environment for employees and stakeholders.

Environmental Sustainability: ISO 14001 and ISO 50001 certifications demonstrate a commitment to sustainable practices, enhancing corporate social responsibility (CSR) credentials.

Risk Management: ISO certifications facilitate better risk identification and management, reducing downtime and potential liabilities.

Enhance the quality and safety of your railway equipment manufacturing and repair operations. Contact Pacific Certifications at support@pacificcert.com or +91-8595603096 for certification solutions.

In 2024, the railway industry is seeing a surge in demand for sustainable and digitalized solutions. Governments worldwide are prioritizing investments in green rail technologies, and ISO standards like 14001 and 50001 are becoming integral to such initiatives. Furthermore, the integration of IoT and AI in railway manufacturing highlights the importance of ISO 27001 for information security.

With global rail markets projected to grow steadily, manufacturers and repair units with ISO certifications are well-positioned to capitalize on emerging opportunities and stay ahead of the competition.

Ready to elevate your business to global standards? Partner with Pacific Certifications to achieve ISO certifications for railway equipment manufacturing and repair. Let us help you unlock new opportunities, enhance quality, and ensure compliance with international benchmarks.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Railway Equipment Manufacturing and Repair business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Railway Equipment Manufacturing and Repair

ISO standards ensure that railway equipment meets international quality, safety, and environmental benchmarks, enhancing reliability and operational efficiency.

ISO/TS 22163 is specifically tailored for the railway sector, addressing its unique quality management requirements.

ISO 14001 helps manufacturers reduce their environmental footprint by promoting efficient resource use and waste management.

Yes, ISO 45001 focuses on workplace safety, reducing risks and fostering a healthier work environment

Pacific Certifications offers expert audit and certification services to help businesses comply with ISO standards and achieve certification efficiently.

The adoption of green technologies and digital solutions is driving demand for ISO certifications like 14001, 50001, and 27001 in the railway sector.

Read More at: Blogs by Pacific Certifications