ISO Certifications for Pump and Compressor Manufacturing Businesses, Requirements and Benefits

ISO certifications have become synonymous with quality and reliability in today’s manufacturing landscape. For pump and compressor manufacturers, adherence to ISO standards is critical differentiator in an industry where precision and performance are non-negotiable.

ISO develops globally recognized standards to ensure quality, efficiency, and environmental responsibility across industries. In pump and compressor manufacturing, ISO certifications provide assurance that products meet international benchmarks. They enhance credibility and drive excellence, benefiting manufacturers and end-users alike.

The significance of ISO standards extends to optimizing processes, reducing waste, and improving customer satisfaction. Manufacturers adhering to these standards demonstrate their commitment to delivering high-performance products while maintaining compliance with industry regulations.

If you’re seeking ISO certification for Pump and Compressor Manufacturing, contact us at support@pacificcert.com or call +91-8595603096 for expert assistance.

Applicable ISO Standards for Pump and Compressor Manufacturing

A range of ISO standards is applicable to pump and compressor manufacturing, each addressing specific facets of quality, safety, and environmental management:

ISO 9001: Quality Management Systems (QMS): This is the cornerstone of quality assurance for manufacturers. ISO 9001 focuses on process optimization, risk management, and continual improvement. It ensures that products meet customer and regulatory requirements consistently.

ISO 14001: Environmental Management Systems (EMS): Environmental sustainability is crucial in modern manufacturing. ISO 14001 guides organizations in reducing their environmental footprint, managing resources efficiently, and complying with environmental regulations.

ISO 45001: Occupational Health and Safety (OHS): Pump and compressor manufacturing involves labor-intensive processes. ISO 45001 ensures a safe workplace by identifying potential hazards, reducing risks, and enhancing employee well-being.

ISO 29001: Quality for Oil and Gas Industry: This standard is particularly relevant for manufacturers catering to the oil and gas sector. It focuses on quality management systems specific to the petroleum, petrochemical, and natural gas industries, ensuring equipment reliability and safety.

ISO 20816: Vibration Measurement and Evaluation: Pumps and compressors often deal with high vibration levels. ISO 20816 provides guidelines for measuring and managing vibration to maintain operational stability and prevent equipment failures.

ISO 12100: Safety of Machinery: This standard offers principles for designing safe machinery, ensuring that equipment used in manufacturing processes adheres to safety protocols and minimizes risks to operators.

ISO 50001: Energy Management Systems (EnMS): Energy efficiency is critical in pump and compressor manufacturing. ISO 50001 helps organizations optimize energy use, reduce costs, and minimize greenhouse gas emissions.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in auditing and issuing ISO certifications for pump and compressor manufacturers. With extensive experience in compliance assessments, we provide organizations with the necessary certification to enhance their market reputation and operational efficiency.

Our auditing process is thorough, impartial, and aligned with international guidelines. We ensure your manufacturing operations adhere to the highest standards, paving the way for long-term success and customer trust.

Contact us for ISO certification for Pump and Compressor Manufacturing at support@pacificcert.com or phone +91-8595603096.

Requirements of ISO Certifications for Pump and Compressor Manufacturing

Meeting ISO standards involves adhering to detailed requirements tailored to each certification. Here’s a brief overview:

For ISO 9001:

- Develop a documented quality management system.

- Focus on customer satisfaction and process improvement.

- Conduct regular internal audits and management reviews.

For ISO 14001:

- Identify environmental aspects and impacts of your operations.

- Establish objectives for resource conservation and waste reduction.

- Implement monitoring systems for compliance with environmental laws.

For ISO 45001:

- Implement a risk assessment framework for workplace safety.

- Provide appropriate training and protective equipment for employees.

- Develop a culture of safety through regular inspections and updates.

For ISO 29001:

- Maintain strict quality controls specific to the oil and gas industry.

- Ensure traceability and reliability of components.

- Address sector-specific risks, such as high-pressure applications.

For ISO 50001:

- Set measurable energy-saving goals.

- Use energy performance indicators for continuous monitoring.

- Optimize processes to reduce energy consumption.

Manufacturers should maintain detailed records of compliance and ensure all employees are trained in the relevant requirements.

For professional guidance on ISO certification for Pump and Compressor Manufacturing, email us at support@pacificcert.com or call +91-8595603096.

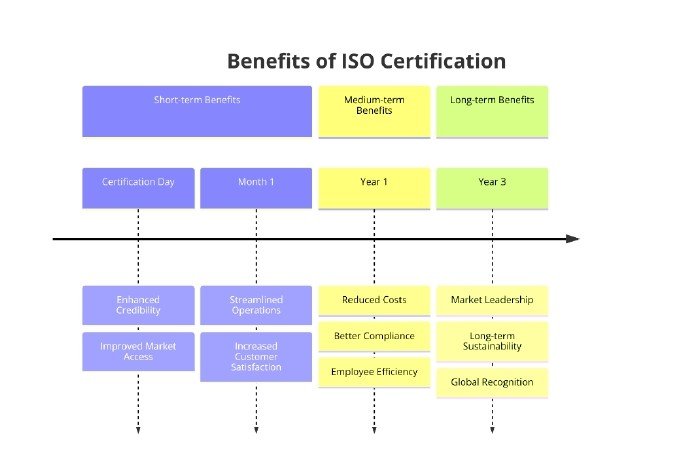

Benefits of ISO Certifications for Pump and Compressor Manufacturing

ISO certifications deliver multifaceted benefits, empowering manufacturers to stand out in a competitive market:

Product Quality: ISO standards guarantee that pumps and compressors meet high-quality benchmarks, resulting in reliable, durable, and efficient products.

Compliance: Certifications streamline compliance with national and international regulations, mitigating risks associated with non-compliance.

Customer Trust: ISO certifications reassure customers of a manufacturer’s commitment to excellence, fostering long-term loyalty and repeat business.

Efficiency: Implementing ISO standards minimizes waste, reduces errors, and optimizes processes, leading to cost savings and higher productivity.

Market Access: Certified manufacturers enjoy easier access to global markets and contracts, particularly in industries like oil and gas, where certifications are often mandatory.

Employee Safety and Satisfaction: Standards such as ISO 45001 create safer work environments, boosting employee morale and reducing workplace incidents.

Environmental Responsibility: ISO 14001 and ISO 50001 help organizations align with global sustainability goals, enhancing their reputation as environmentally conscious manufacturers.

This year is poised to bring a significant focus on energy efficiency and digital integration in pump and compressor manufacturing. With stricter environmental regulations, ISO 14001 and ISO 50001 certifications are becoming more critical than ever. The industry is also witnessing a surge in smart manufacturing practices, with IoT-enabled compressors gaining traction.

Manufacturers adopting ISO certifications are better positioned to integrate these advancements while ensuring compliance and maintaining competitive advantages.

Whether you’re pursuing ISO 9001 for quality, ISO 14001 for environmental management, or ISO 45001 for workplace safety, our expert auditors are here to guide you through the certification process.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Pump and Compressor Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Pump and Compressor Manufacturing

ISO certifications ensure quality, safety, and compliance with international standards, boosting market credibility and operational efficiency.

Key certifications include ISO 9001 (Quality), ISO 14001 (Environmental Management), ISO 45001 (Occupational Safety), ISO 29001 (Oil and Gas Industry), and ISO 50001 (Energy Management).

ISO 14001 helps manufacturers minimize their environmental impact by reducing waste, conserving resources, and complying with environmental regulations.

No, Pacific Certifications specializes in auditing and issuing ISO certifications, ensuring your organization meets all necessary requirements.

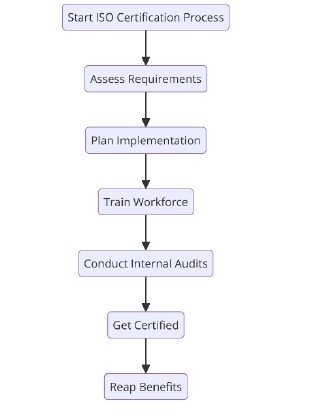

The process involves a comprehensive audit by a certification body, which evaluates your compliance with the specific ISO standard requirements.

ISO 9001 provides a framework for maintaining consistent quality, enhancing customer satisfaction, and driving continuous improvement in manufacturing processes.

Read More at: Blogs by Pacific Certifications