ISO Certifications for Plastic Bottle Manufacturing Businesses, Requirements and Benefits

The manufacturing of plastic bottles is a highly regulated industry that requires strict adherence to international standards to ensure quality and environmental compliance. Obtaining ISO certifications for plastic bottle manufacturing is a vital step in gaining market trust and expanding your business globally.

The International Organization for Standardization develops globally recognized standards to improve quality, safety & environmental management. For the plastic bottle manufacturing industry, ISO certifications establish benchmarks for producing high-quality, durable, and sustainable products.

These certifications ensure that manufacturers adopt strict guidelines, enabling them to meet customer expectations while complying with legal and environmental standards. Moreover, ISO certifications foster continuous improvement and innovation, crucial for thriving in a competitive marketplace.

By implementing ISO standards, plastic bottle manufacturers can achieve:

- Consistent product quality.

- Reduced environmental impact.

- Better resource management.

If you’re seeking ISO certification for Plastic Bottle Manufacturing, contact us at support@pacificcert.com or call +91-8595603096 for expert assistance.

Applicable ISO Standards for Plastic Bottle Manufacturing

A variety of ISO standards are applicable to the plastic bottle manufacturing sector, addressing quality management, environmental responsibility, and safety. Here’s an overview:

ISO 9001: Quality Management System (QMS): ISO 9001 is the cornerstone of quality management. It helps manufacturers develop robust processes to ensure consistent product quality and customer satisfaction. It emphasizes risk-based thinking, continuous improvement, and customer-focused practices.

ISO 14001: Environmental Management System (EMS): Given the environmental concerns associated with plastic production, ISO 14001 is critical. It helps manufacturers identify and mitigate environmental risks, reduce waste, and improve energy efficiency, aligning with global sustainability goals.

ISO 45001: Occupational Health and Safety (OH&S): Plastic bottle manufacturing involves processes that can pose risks to workers’ safety. ISO 45001 ensures a safe working environment by minimizing workplace hazards and promoting employee well-being.

ISO 22000: Food Safety Management System: For manufacturers producing plastic bottles for food and beverages, ISO 22000 ensures that materials used are safe and free from contamination. This certification covers hazard control and traceability throughout the supply chain.

ISO 50001: Energy Management System: This standard helps manufacturers optimize energy usage, reducing operational costs and the carbon footprint. Energy efficiency is a growing priority for industries worldwide.

ISO 19011: Guidelines for Auditing Management Systems: ISO 19011 provides a framework for auditing management systems, ensuring that the processes for ISO certifications are efficient, transparent, and objective.

ISO 11469: Identification and Marking of Plastics Products: This standard is specific to plastics, ensuring that products are appropriately marked for identification and recycling purposes, aligning with sustainability initiatives.

Click here to find out more applicable standards to your industry

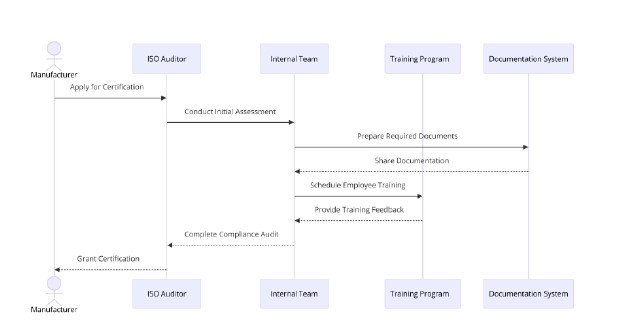

At Pacific Certifications, we specialize in auditing and issuing ISO certifications for plastic bottle manufacturers. With a deep understanding of the industry and applicable standards, our team ensures a seamless certification process, guiding manufacturers toward compliance with ISO requirements.

Our role involves:

- Conducting audits to assess compliance with relevant standards.

- Identifying gaps and ensuring readiness for certification.

- Issuing certifications to demonstrate adherence to ISO standards.

Choosing Pacific Certifications means partnering with an experienced certification body committed to fostering trust and excellence in your operations.

Take your plastic bottle business to the next level! For ISO certification services, contact us via email at support@pacificcert.com or call +91-8595603096.

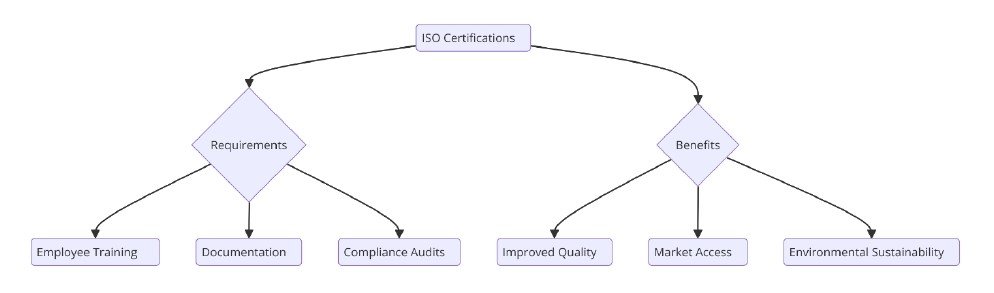

Requirements of ISO Certifications for Plastic Bottle Manufacturing

Each ISO standard has unique requirements tailored to its focus area. Here are some key requirements that plastic bottle manufacturers must meet:

ISO 9001: Requirements

- Define quality objectives and establish a quality policy.

- Document processes and ensure proper resource allocation.

- Conduct regular internal audits to maintain system effectiveness.

ISO 14001: Requirements

- Conduct environmental impact assessments.

- Develop and implement environmental objectives and programs.

- Monitor and review environmental performance regularly.

ISO 45001: Requirements

- Identify workplace hazards and implement risk controls.

- Provide safety training and establish emergency preparedness plans.

- Conduct periodic reviews of OH&S practices.

ISO 22000: Requirements

- Identify and control food safety hazards.

- Maintain traceability of materials throughout production.

- Develop a food safety management plan.

ISO 50001: Requirements

- Establish an energy management policy.

- Track energy usage and set improvement goals.

- Integrate energy efficiency into operational practices.

General Documentation and Training

Regardless of the standard, manufacturers must maintain meticulous documentation and ensure employees are adequately trained to implement and sustain the management systems.

Streamline your operations with ISO certification. Get in touch with us at support@pacificcert.com or call +91-8595603096 for guidance tailored to Plastic Bottle Manufacturing.

Benefits of ISO Certifications for Plastic Bottle Manufacturing

ISO certifications offer a wide range of benefits that extend beyond compliance. Here’s why plastic bottle manufacturers should prioritize these standards:

Product Quality: ISO certifications ensure consistency in manufacturing processes, leading to high-quality plastic bottles that meet customer expectations.

Environmental Responsibility: By aligning with ISO 14001, manufacturers reduce waste and environmental impact, addressing growing consumer and regulatory demands for sustainability.

Worker Safety and Well-Being: ISO 45001 certification demonstrates a commitment to worker safety, reducing accidents and fostering a positive workplace culture.

Market Competitiveness: ISO-certified manufacturers gain a competitive edge, as customers and partners prioritize businesses with verified compliance to global standards.

Regulatory Compliance: Adhering to ISO standards ensures compliance with local and international regulations, reducing the risk of legal and financial penalties.

Cost Savings: Efficient resource and energy management, as guided by ISO standards, result in significant cost reductions over time.

The global plastic bottle manufacturing industry is evolving rapidly. This year, sustainability is the key driver, with a growing emphasis on biodegradable plastics and circular economy models. Regulations around single-use plastics are tightening, compelling manufacturers to innovate and adopt environmentally friendly practices.

ISO certifications are becoming indispensable for demonstrating compliance with these trends, particularly ISO 14001 for sustainability and ISO 50001 for energy efficiency. Forward-thinking manufacturers are leveraging these certifications to align with market demands and secure long-term growth. Partner with Pacific Certifications, your trusted certification body, to ensure seamless compliance with international standards.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Plastic Bottle Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Plastic Bottle Manufacturing

ISO 9001 ensures consistent product quality by establishing a robust quality management system. It is vital for meeting customer expectations and maintaining competitive advantage.

ISO 14001 helps manufacturers manage their environmental responsibilities, reduce waste, and comply with sustainability regulations, enhancing their market reputation.

Yes, ISO 45001 is crucial for ensuring a safe workplace, reducing accidents, and promoting employee well-being in a manufacturing setting.

ISO 22000 ensures that plastic bottles intended for food and beverages meet stringent safety standards, minimizing contamination risks.

The duration varies depending on the complexity of the organization’s processes and its readiness for certification, typically ranging from a few months to a year.

Pacific Certifications offers expertise, transparency, and a streamlined process, ensuring your compliance journey is efficient and stress-free.

Read More at: Blogs by Pacific Certifications