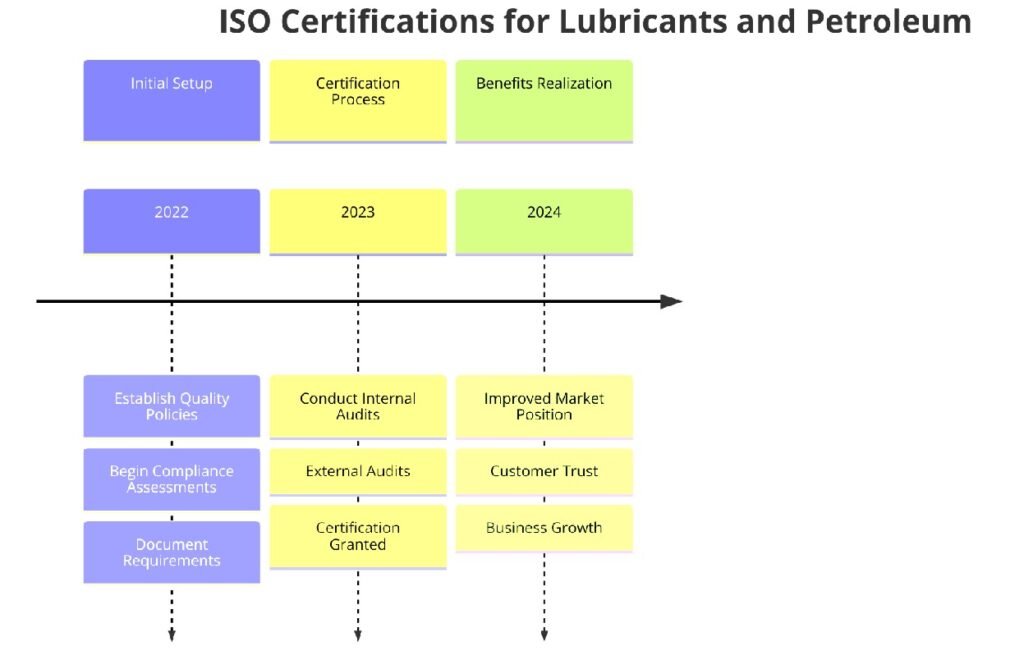

ISO Certifications for Lubricants and Petroleum Product Manufacturing Businesses, Requirements and Benefits

ISO certifications are a cornerstone for maintaining quality, safety, and environmental compliance in lubricant and petroleum product manufacturing. By implementing international standards, manufacturers enhance credibility & ensure compliance in the global market.

ISO develops globally recognized standards that cater to various industries, including the lubricant and petroleum manufacturing sector. These standards ensure uniformity, reliability, and excellence in production processes and final products.

For lubricants and petroleum products, ISO standards address critical aspects such as product quality, environmental impact, safety measures, and operational efficiency. Adopting these certifications signals a commitment to producing superior products while adhering to regulatory requirements.

Whether your organization deals with base oil processing, lubricant blending, or petroleum refining, implementing ISO standards provides a structured framework for quality assurance.

Send your inquiries and requirements to support@pacificcert.com. Our team will respond promptly with the details you need to start the certification process.

Applicable ISO Standards for Lubricants and Petroleum Product Manufacturing

Navigating ISO standards can seem daunting, but understanding the specific ones applicable to the lubricant and petroleum industry is essential for seamless certification. Below are some of the primary ISO standards relevant to this sector:

ISO 9001: Quality Management Systems (QMS): ISO 9001 ensures a focus on customer satisfaction, process optimization, and continual improvement. It enables lubricant and petroleum manufacturers to maintain consistent quality while minimizing waste and errors.

ISO 14001: Environmental Management Systems (EMS): This standard aids organizations in managing their environmental responsibilities. It ensures compliance with environmental laws and promotes sustainable operations, reducing the carbon footprint associated with petroleum production.

ISO 45001: Occupational Health and Safety (OH&S): Safety is a critical concern in the petroleum and lubricants industry. ISO 45001 provides a framework to identify, control, and mitigate workplace hazards, ensuring the safety of employees and stakeholders.

ISO 29001: Quality Management Systems for Oil and Gas: Developed in collaboration with the oil and gas industry, ISO 29001 addresses sector-specific quality management needs, including those related to petroleum and lubricants.

ISO 50001: Energy Management Systems (EnMS): Energy efficiency is key in reducing operational costs and environmental impacts. ISO 50001 provides guidelines to optimize energy consumption in manufacturing processes.

ISO 21469: Lubricants for Incidental Product Contact: For food-grade lubricants, this standard ensures safety and hygiene. Manufacturers producing lubricants for food or pharmaceutical industries must comply with this standard to guarantee product safety.

ISO 17025: Laboratory Competence: Testing and validation of petroleum products are crucial. ISO 17025 certifies that laboratories used in quality checks meet international competence standards.

ISO 10012: Measurement Management Systems: Precision in measurement impacts product consistency and quality. ISO 10012 ensures robust measurement management systems are in place.

Click here to find out more applicable standards to your industry

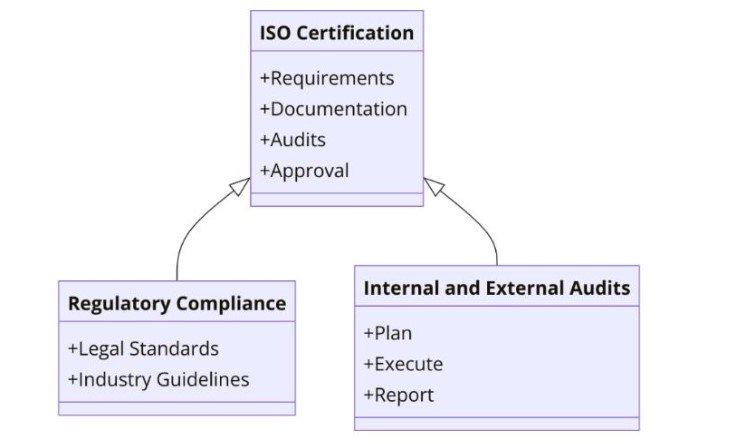

At Pacific Certifications, we specialize in auditing and issuing ISO certifications tailored to the needs of lubricant and petroleum manufacturers. With years of experience, we provide seamless, professional services that guide you through the certification process.

Our approach ensures compliance with international standards and supports organizations in building trust and credibility. From the initial audit to certification issuance, Pacific Certifications works as your partner in achieving operational excellence.

Contact us at support@pacificcert.com to schedule a one-on-one consultation with our team. We’ll guide you through the process step by step.

Requirements of ISO Certifications for Lubricants and Petroleum Product Manufacturing

Here’s a breakdown of the specific requirements for each ISO standard relevant to the lubricant and petroleum product manufacturing industry:

ISO 9001: Quality Management Systems (QMS)

- Quality Policy and Objectives: Develop and communicate a clear quality policy that aligns with organizational goals.

- Process Approach: Define and document processes to ensure effective management and resource optimization.

- Customer Focus: Understand customer requirements and ensure their needs are consistently met.

- Risk and Opportunity Management: Identify and address risks and opportunities impacting product quality.

- Performance Evaluation: Regularly monitor, measure, and analyze quality performance.

- Continuous Improvement: Establish mechanisms for identifying and implementing improvements.

ISO 14001: Environmental Management Systems (EMS)

- Environmental Policy: Create and maintain a policy that reflects the organization’s commitment to sustainability.

- Environmental Aspect Identification: Identify and manage environmental aspects and impacts related to manufacturing activities.

- Compliance Obligations: Stay updated with and adhere to legal and regulatory environmental requirements.

- Lifecycle Perspective: Assess environmental impacts across the product lifecycle, from raw material sourcing to disposal.

- Emergency Preparedness: Establish response plans for potential environmental incidents.

ISO 45001: Occupational Health and Safety (OH&S)

- Hazard Identification: Identify workplace hazards and evaluate associated risks.

- OH&S Policy: Develop a safety policy emphasizing the health and well-being of employees.

- Worker Participation: Engage employees in identifying safety issues and implementing solutions.

- Incident Investigation: Establish processes for investigating workplace incidents and implementing corrective actions.

- Legal Compliance: Ensure compliance with occupational health and safety laws.

ISO 50001: Energy Management Systems (EnMS)

- Energy Policy: Develop a policy outlining the organization’s commitment to energy efficiency.

- Energy Planning: Identify significant energy uses and set objectives for improvement.

- Energy Performance Indicators (EnPIs): Define and monitor metrics to track energy performance.

- Energy Review: Conduct regular reviews to identify inefficiencies and opportunities for optimization.

- Operational Control: Implement operational controls to manage energy-intensive activities.

ISO 29001: Quality Management for Oil and Gas Industry

- Product Traceability: Ensure the traceability of products and components.

- Supply Chain Management: Implement robust processes for managing suppliers and contractors.

- Contingency Planning: Prepare for potential disruptions in supply chains or manufacturing processes.

- Defect Prevention: Emphasize preventative measures to reduce defects and improve quality.

ISO 21469: Safety of Lubricants for Incidental Contact

- Hygiene Management: Maintain cleanliness in production and storage areas.

- Material Safety: Ensure raw materials used in lubricants meet safety standards.

- Testing and Validation: Conduct tests to verify product safety and performance.

- Packaging and Labeling: Use appropriate packaging to prevent contamination and provide clear labels with safety information.

ISO 17025: Competence of Testing and Calibration Laboratories

Testing laboratories used in quality checks must meet the following requirements:

- Competence and Training: Ensure personnel conducting tests are skilled and qualified.

- Valid Test Methods: Use standardized and validated testing methods for reliable results.

- Quality Assurance: Implement quality management practices in testing procedures.

- Traceable Measurements: Maintain traceability of measurements to ensure accuracy.

Email support@pacificcert.com to receive detailed information about the certification process, timelines, and costs.

Benefits of ISO Certifications for Lubricants and Petroleum Product Manufacturing

Adopting ISO standards delivers significant advantages for lubricant and petroleum manufacturers. These benefits extend beyond compliance to include operational, financial, and reputational gains:

Product Quality: ISO certification assures customers that your products meet international benchmarks for quality, consistency, and safety. This builds trust and customer loyalty.

Regulatory Compliance: With evolving regulations, ISO standards provide a structured approach to compliance, minimizing risks of fines or legal issues.

Efficiency: Streamlined processes and reduced waste are hallmarks of ISO-certified organizations. Standards like ISO 50001 promote energy efficiency, directly impacting cost savings.

Market Competitiveness: ISO certification differentiates your organization in a crowded marketplace. It signals a commitment to excellence, which appeals to global customers and business partners.

Environmental Responsibility: ISO 14001 certification demonstrates your commitment to sustainability, aligning with market demands for environmentally conscious operations.

Safety Measures: With ISO 45001, organizations can create a safer workplace, reducing accidents and boosting employee morale.

In 2024, sustainability and innovation are dominating the lubricant and petroleum industry. The demand for bio-based lubricants is on the rise as manufacturers explore alternatives to reduce environmental impacts. Additionally, digital transformation is influencing how manufacturers monitor quality and safety in real time.

According to recent market research, organizations implementing ISO standards are better positioned to meet these demands, as the certifications provide frameworks for adapting to these evolving trends. At Pacific Certifications, we ensure a seamless certification process, helping you achieve compliance and operational excellence.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Lubricants and Petroleum Product Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Lubricants and Petroleum Product Manufacturing

ISO standards are internationally recognized frameworks ensuring quality, safety, and environmental compliance in manufacturing processes.

Key standards include ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 21469, each addressing specific aspects like quality, safety, and energy management.

ISO 9001 enhances product quality and process efficiency, ensuring customer satisfaction and consistency.

Yes, ISO 14001 and ISO 50001 specifically promote sustainable practices, including environmental management and energy efficiency.

Pacific Certifications conducts audits and issues ISO certifications, ensuring your organization meets international standards.

ISO 45001 helps create a safer workplace by identifying and mitigating hazards, ensuring employee well-being.

Read More at: Blogs by Pacific Certifications