ISO Certifications for Industrial Gas Manufacturing Businesses, Requirements and Benefits

The industrial gas manufacturing industry operates in a dynamic and safety-critical environment. From producing oxygen for healthcare to delivering carbon dioxide for food and beverage industries, manufacturers face unique challenges that demand the highest operational standards. ISO certifications for industrial gas manufacturing serve as a benchmark for quality, safety, and environmental sustainability, helping businesses meet regulatory requirements and customer expectations alike.

ISO standards are globally recognized guidelines that ensure businesses operate efficiently, safely, and responsibly. In industrial gas manufacturing, these standards play a vital role in addressing the complexities of production, storage, transportation, and compliance.

ISO certifications provide a systematic framework to manage risks, improve operational efficiency, and ensure the consistent quality of gases like oxygen, nitrogen, hydrogen, and more. They also highlight an organization’s commitment to safety and environmental stewardship, essential in this high-risk sector.

Why ISO Standards Matter in Industrial Gas Manufacturing

Industrial gases are critical in multiple sectors, including healthcare, electronics, energy, and construction. Any deviation in production quality or safety protocols could have severe consequences. ISO certifications ensure stringent controls, reducing risks while maintaining the highest operational standards.

If you’re seeking ISO certification for industrial gas manufacturing, we’re here to assist. Contact us at support@pacificcert.com or call +91-8595603096 for expert guidance.

Applicable ISO Standards for Industrial Gas Manufacturing

Several ISO standards are directly relevant to the industrial gas manufacturing industry. These standards cover quality management, environmental sustainability, occupational safety, and more.

ISO 9001: Quality Management Systems

ISO 9001 ensures that businesses deliver consistent quality in their processes and products. For industrial gas manufacturers, this involves robust quality controls from raw material sourcing to product delivery.

ISO 14001: Environmental Management Systems

Industrial gas production often involves significant environmental impacts. ISO 14001 helps organizations identify, monitor, and mitigate their environmental footprint, ensuring compliance with environmental regulations.

ISO 45001: Occupational Health and Safety

Safety is paramount in industrial gas manufacturing. ISO 45001 sets a framework to manage workplace risks effectively, protecting workers from potential hazards like gas leaks or equipment failures.

ISO 50001: Energy Management Systems

Given the energy-intensive nature of gas production, ISO 50001 enables manufacturers to optimize energy usage, reduce costs, and minimize greenhouse gas emissions.

ISO 22000: Food Safety Management Systems

This standard is crucial for manufacturers producing food-grade gases, such as carbon dioxide used in beverages or nitrogen for food preservation. ISO 22000 ensures adherence to stringent food safety requirements.

ISO 17025: Testing and Calibration Laboratories

For manufacturers with in-house testing labs, ISO 17025 certification ensures that testing methods and results meet global standards, boosting reliability and credibility.

Other Relevant Standards

- ISO 20421 (Cryogenic Vessels): Ensures the safe storage and transportation of industrial gases.

- ISO 10298 (Gas Cylinder Content Labeling): Guides the labeling of cylinders for safety and regulatory compliance.

- ISO 31000 (Risk Management): Provides principles for identifying and mitigating risks across operations.

Click here to find out more applicable standards to your industry

As a trusted certification body, Pacific Certifications offers comprehensive support to businesses seeking ISO certifications for industrial gas manufacturing. Our expertise ensures a seamless audit process, helping you demonstrate compliance with applicable standards. From initial application to final certification issuance, Pacific Certifications works as a reliable partner, ensuring that every step of your certification journey is clear, efficient, and hassle-free.

Our Key Services

- Certification audits by experienced professionals.

- Transparent guidance on ISO standard requirements.

- Timely issuance of globally recognized ISO certifications.

Looking to elevate your industrial gas manufacturing standards with ISO certification? Contact support@pacificcert.com or call us at +91-8595603096.

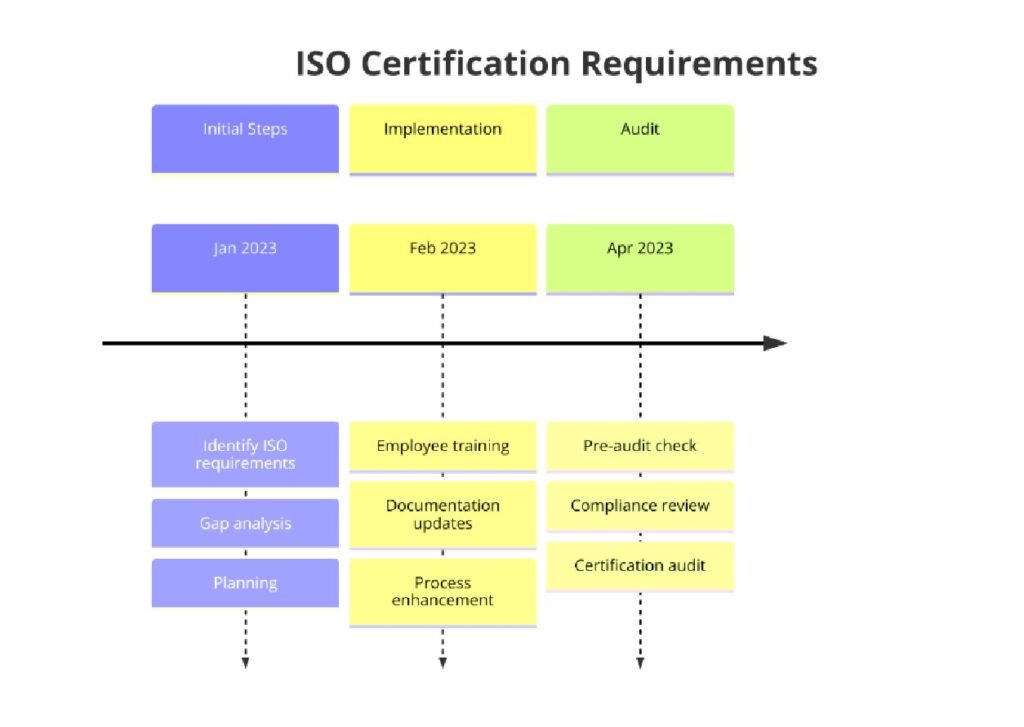

Requirements of ISO Certifications for Industrial Gas Manufacturing

Each ISO standard has specific requirements that organizations must meet to achieve certification. Below are some general and industry-specific expectations:

ISO 9001 Requirements

- Develop and maintain documented quality management systems (QMS).

- Conduct regular internal audits to ensure compliance with quality standards.

- Implement a continuous improvement culture.

ISO 14001 Requirements

- Identify environmental impacts of operations and establish measurable objectives to mitigate them.

- Develop emergency response plans for potential environmental incidents.

- Monitor and report on sustainability initiatives.

ISO 45001 Requirements

- Conduct risk assessments to identify workplace hazards.

- Implement training programs to enhance worker safety awareness.

- Establish incident reporting and investigation protocols.

ISO 50001 Requirements

- Conduct energy audits to identify areas of improvement.

- Develop energy-saving policies and action plans.

- Monitor energy performance indicators (EnPIs).

Documentation and Records

- Maintain detailed records of production processes, safety protocols, and quality controls.

- Ensure compliance with traceability requirements for gases, especially those used in healthcare or food industries.

Achieve excellence in industrial gas manufacturing with ISO certification. Email us at support@pacificcert.com or call +91-8595603096 for assistance.

Benefits of ISO Certifications for Industrial Gas Manufacturing

Achieving ISO certifications brings significant advantages to industrial gas manufacturers, ensuring long-term growth and sustainability.

Safety and Risk Management: Compliance with standards like ISO 45001 and ISO 31000 ensures robust safety measures, reducing workplace accidents and operational risks.

Operational Efficiency: ISO 9001 and ISO 50001 certifications streamline processes, resulting in reduced waste, optimized energy usage, and cost savings.

Market Credibility and Customer Trust: Certified organizations are perceived as more reliable, gaining a competitive edge in global markets. Certifications like ISO 22000 enhance trust in food-grade gas production.

Regulatory Compliance: Adherence to ISO standards ensures alignment with international laws and regulations, reducing the risk of penalties and enhancing market access.

Sustainability Goals: ISO 14001 and ISO 50001 certifications help businesses reduce their carbon footprint, supporting global sustainability initiatives and appealing to eco-conscious stakeholders.

As of 2024, there is a growing emphasis on green hydrogen production, supported by advancements in renewable energy. Many industrial gas manufacturers are aligning their operations with ISO 50001 to reduce energy consumption and support decarbonization efforts. This trend highlights the importance of ISO certifications in staying competitive amidst evolving market dynamics.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Industrial Gas Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Industrial Gas Manufacturing

ISO certifications ensure that industrial gas manufacturers adhere to international standards for quality, safety, and environmental sustainability, enhancing operational efficiency and market credibility.

Key standards include ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 22000, covering quality, safety, energy management, and food safety.

ISO 45001 provides a framework for identifying workplace risks, implementing safety protocols, and reducing the likelihood of accidents in high-risk environments.

Yes, ISO 22000 ensures compliance with food safety requirements, building trust among customers in the food and beverage industry.

Pacific Certifications conducts audits and issues ISO certifications, ensuring businesses meet all necessary compliance requirements without providing consultancy or implementation services.

Standards like ISO 14001 and ISO 50001 help organizations minimize their environmental impact and optimize energy use, supporting global sustainability initiatives.

Read More at: Blogs by Pacific Certifications