ISO Certifications for Flour and Grain Mill Product Manufacturing Businesses, Requirements and Benefits

Ensuring quality and safety in flour and grain mill product manufacturing is critical for consumer trust and regulatory compliance. ISO certifications provide an internationally recognized framework to improve operational efficiency, ensure product safety & build credibility. For manufacturers in this sector, ISO standards are essential tools for meeting customer demands and maintaining market relevance.

Introduction to ISO Standards for Flour and Grain Mill Product Manufacturing

The flour and grain milling industry operates in a highly regulated environment where quality, hygiene, and safety are paramount. ISO develops globally recognized standards that establish benchmarks for quality management, food safety, environmental responsibility and more. By obtaining ISO certifications, flour and grain mill manufacturers can improve their processes and ensure compliance.

From raw grain storage to the milling and packaging stages, ISO standards minimize risks and increase customer satisfaction. The ISO framework also aligns operations with global best practices, ensuring manufacturers remain competitive in international markets.

Looking to obtain ISO certification for your flour and grain mill product manufacturing? Contact us today at support@pacificcert.com or call +91-8595603096 for expert assistance.

Applicable ISO Standards for Flour and Grain Mill Product Manufacturing

Several ISO standards are highly relevant to flour and grain mill product manufacturing. Below are the key standards applicable to this industry:

ISO 9001: Quality Management System (QMS): ISO 9001 establishes criteria for maintaining consistent quality across products and services. This certification ensures that flour and grain mill processes are optimized for efficiency and customer satisfaction.

ISO 22000: Food Safety Management System (FSMS): ISO 22000 integrates food safety principles with quality management, ensuring that manufacturers meet rigorous food safety requirements. This standard is essential for managing risks like contamination or spoilage in grain milling.

ISO 14001: Environmental Management System (EMS): Environmental sustainability is increasingly important in modern manufacturing. ISO 14001 guides organizations in managing their environmental responsibilities effectively, from waste management to energy efficiency.

ISO 45001: Occupational Health and Safety Management System: ISO 45001 ensures that manufacturers prioritize the health and safety of their workforce. For flour and grain mill operations, this can include managing dust explosion risks, machinery safety, and employee well-being.

ISO 50001: Energy Management System: Energy efficiency is a critical concern for manufacturers. ISO 50001 helps organizations monitor and optimize energy usage, reducing costs and environmental impact.

ISO 31000: Risk Management: For manufacturers handling bulk grains, risks like contamination, supply chain disruption, and operational downtime are significant. ISO 31000 provides a framework for identifying and managing these risks effectively.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing certification services tailored to your specific needs. With years of expertise in ISO certifications, we conduct thorough audits to evaluate your compliance with applicable standards. Our auditors work with integrity and professionalism, ensuring you meet ISO requirements seamlessly.

Whether you’re seeking ISO 9001 for quality, ISO 22000 for food safety, or ISO 14001 for environmental management, Pacific Certifications is your trusted partner for achieving certification.

To begin your ISO certification journey, contact us at support@pacificcert.com today!

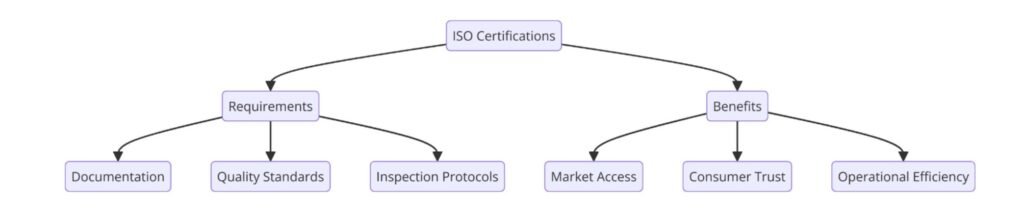

Requirements of ISO Certifications for Flour and Grain Mill Product Manufacturing

ISO 9001 Requirements

- Develop and maintain a documented Quality Management System (QMS).

- Conduct regular internal audits and management reviews.

- Implement a customer feedback mechanism to drive continuous improvement.

ISO 22000 Requirements

- Hazard Analysis and Critical Control Points (HACCP) implementation.

- Establish effective traceability systems for raw materials and finished products.

- Ensure comprehensive employee training in food safety practices.

ISO 14001 Requirements

- Identify environmental impacts and set improvement goals.

- Implement waste management practices to minimize pollution.

- Regularly monitor energy and resource consumption for optimization.

ISO 45001 Requirements

- Conduct risk assessments for workplace hazards.

- Provide appropriate protective equipment and training to employees.

- Establish protocols for emergency response and incident management.

Ensure quality and compliance with ISO certification. Email support@pacificcert.com or call +91-8595603096 to begin your journey toward certification today.

Benefits of ISO Certifications for Flour and Grain Mill Product Manufacturing

Quality Assurance: ISO certifications like ISO 9001 and ISO 22000 ensure consistent product quality and safety, meeting customer and regulatory expectations.

Operational Efficiency: By aligning processes with ISO standards, manufacturers can identify inefficiencies, reduce waste, and optimize resource utilization.

Global Market Access: ISO certifications are globally recognized, enabling manufacturers to export their products with confidence and meet international buyer requirements.

Risk Mitigation: Standards such as ISO 31000 and ISO 45001 help manufacturers manage operational and workplace risks, ensuring uninterrupted production and employee safety.

Environmental Responsibility: ISO 14001 and ISO 50001 certifications demonstrate a commitment to sustainability, enhancing the brand’s reputation among eco-conscious consumers and partners.

Credibility: An ISO-certified facility signals reliability and professionalism, boosting stakeholder confidence and attracting new business opportunities.

In 2024, sustainability and digital transformation continue to shape the flour and grain milling industry. With rising consumer demand for transparency and eco-friendly products, ISO 14001 and ISO 50001 are gaining traction among manufacturers.

Additionally, advancements in technology such as AI-powered sorting systems and IoT-enabled monitoring tools are helping businesses meet ISO requirements with greater precision. As industry players adopt innovative practices. Pacific Certifications is here to guide you through the certification process, ensuring compliance with ISO standards.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Flour and Grain Mill Product Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Flour and Grain Mill Product Manufacturing

ISO 9001, ISO 22000, ISO 14001, ISO 45001, and ISO 50001 are the key certifications. They address quality, food safety, environmental management, workplace safety, and energy efficiency.

ISO 22000 provides a framework for identifying food safety hazards, implementing preventive controls, and ensuring product traceability, reducing risks of contamination.

ISO certification is not mandatory but is highly beneficial for meeting regulatory requirements, improving operational efficiency, and gaining customer trust.

The duration varies depending on the complexity of operations and the organization’s preparedness. Generally, it takes several months, including audits and compliance adjustments.

Pacific Certifications focuses on certification services, including auditing and issuing certificates. Implementation and training fall outside our scope of services.

Pacific Certifications is a trusted certification body with extensive experience in auditing and certifying businesses in compliance with ISO standards.

Read More at: Blogs by Pacific Certifications