ISO Certifications for Plastic Packaging Material Manufacturing Businesses, Requirements and Benefits

Ensuring quality and sustainability in plastic packaging manufacturing is essential in today’s environmentally conscious world. ISO certifications are globally recognized standards that help manufacturers to meet these expectations while maintaining efficiency and safety.

ISO, sets globally accepted standards for various industries, promoting consistency, quality and safety. For plastic packaging manufacturers, ISO certifications address critical concerns such as product safety, quality management, environmental impact and sustainable practices.

Plastic packaging materials are integral to multiple sectors, including food, pharmaceuticals, and consumer goods. With increasing regulatory scrutiny and consumer demand for eco-friendly solutions, manufacturers must adopt standards that ensure product integrity and environmental responsibility. ISO certifications act as a benchmark, demonstrating commitment to best practices and building trust with customers and stakeholders.

If you’re seeking ISO certification for plastic packaging material manufacturing, reach out to us at support@pacificcert.com or call us at +91-8595603096 for expert guidance and seamless certification services.

Applicable ISO Standards for Plastic Packaging Material Manufacturing

A range of ISO standards applies to plastic packaging manufacturing, each focusing on specific aspects of production, safety, and environmental management:

ISO 9001: Quality Management System (QMS)

ISO 9001 is the cornerstone of quality management. It ensures that manufacturers consistently produce products that meet customer and regulatory requirements. For plastic packaging, this involves streamlined processes, defect prevention, and continuous improvement.

ISO 14001: Environmental Management System (EMS)

With increasing emphasis on sustainability, ISO 14001 is critical for manufacturers. It helps organizations minimize their environmental footprint by managing waste, reducing emissions, and optimizing resource usage.

ISO 45001: Occupational Health and Safety

Safety is paramount in manufacturing. ISO 45001 safeguards employees by addressing workplace hazards, improving safety measures, and fostering a culture of health and safety compliance.

ISO 22000: Food Safety Management System (FSMS)

Plastic packaging for food products must adhere to stringent safety standards. ISO 22000 ensures that food-grade packaging materials are produced under hygienic conditions and meet safety regulations.

ISO 15378: Primary Packaging Materials for Medicinal Products

This standard is specifically for manufacturers of primary packaging for pharmaceuticals. It integrates Good Manufacturing Practices (GMP) with ISO 9001, ensuring compliance with regulatory requirements for medicinal packaging.

ISO 11469: Plastics — Generic Identification and Marking of Products

ISO 11469 promotes transparency in plastic packaging by standardizing the identification and labeling of plastic materials. It aids in recycling and promotes sustainability.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing certification services for ISO standards applicable to the plastic packaging industry. Our expert auditors ensure a seamless certification process, guiding your organization to achieve compliance with industry standards.

We understand the challenges of maintaining high standards while staying competitive. With years of experience, our certification process is designed to add value to your operations, making compliance a stepping stone to excellence.

Achieve ISO Excellence: For reliable and professional ISO certification for plastic packaging manufacturing, email us at support@pacificcert.com or dial +91-8595603096.

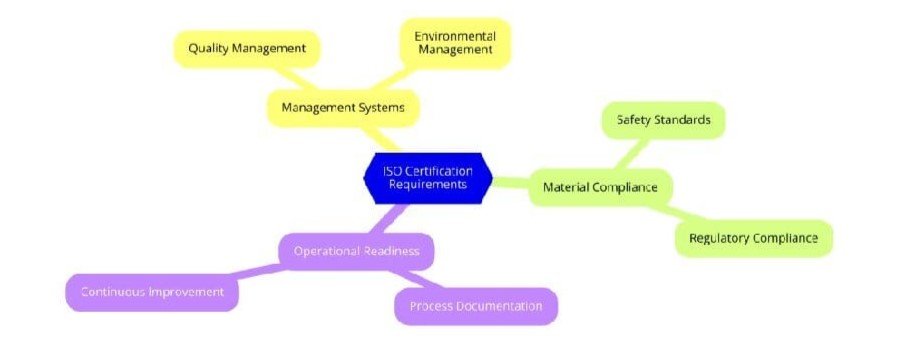

Requirements of ISO Certifications for Plastic Packaging Material Manufacturing

Achieving ISO certification requires adherence to specific criteria tailored to the needs of plastic packaging manufacturing:

Quality Management (ISO 9001)

- Establish a documented quality management system.

- Monitor customer feedback and implement corrective actions.

- Conduct regular internal audits and management reviews.

Environmental Stewardship (ISO 14001)

- Identify and manage environmental aspects, such as waste disposal and energy use.

- Set measurable objectives to reduce the environmental impact.

- Maintain compliance with environmental laws and regulations.

Workplace Safety (ISO 45001)

- Conduct risk assessments to identify workplace hazards.

- Implement training programs for employees on health and safety.

- Develop emergency preparedness and response plans.

Food Safety Compliance (ISO 22000)

- Implement Hazard Analysis and Critical Control Points (HACCP) for food packaging.

- Ensure traceability in the supply chain.

- Maintain hygiene and sanitation standards in manufacturing.

Pharmaceutical Packaging (ISO 15378)

- Document processes specific to pharmaceutical packaging.

- Ensure compliance with medicinal product regulations.

- Focus on traceability, risk management, and defect prevention.

Start your ISO certification process with Pacific Certifications. Reach out via support@pacificcert.com or call +91-8595603096.

Benefits of ISO Certifications for Plastic Packaging Material Manufacturing

Implementing ISO standards offers significant advantages for plastic packaging manufacturers, including:

Product Quality: ISO certifications ensure consistent product quality, meeting customer expectations and minimizing defects.

Operational Efficiency: Standardized processes reduce waste, optimize resources, and enhance productivity.

Regulatory Compliance: ISO standards align with global regulations, helping manufacturers avoid penalties and maintain market access.

Sustainability: ISO 14001 certification demonstrates your commitment to sustainability, improving your reputation and opening doors to eco-conscious markets.

Customer Trust: ISO-certified manufacturers are perceived as reliable and professional, fostering customer loyalty and building brand credibility.

The plastic packaging industry is shaped by technological advancements and stringent environmental policies. A significant trend is the shift toward biodegradable plastics and recycling initiatives. ISO 14001 certification is increasingly important as manufacturers strive to meet government mandates for reduced carbon footprints.

Moreover, digital transformation is revolutionizing quality management systems, with smart technologies streamlining compliance and monitoring. As consumer preferences lean toward sustainability, ISO standards ensure manufacturers remain competitive and aligned with market demands.

Achieving ISO certification is a transformative step for your plastic packaging manufacturing business. Let Pacific Certifications guide you through the process, ensuring your operations meet global standards for quality and sustainability.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Plastic Packaging Material Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Plastic Packaging Material Manufacturing

ISO certification demonstrates adherence to international standards for quality, safety, and environmental management. It is vital for building customer trust and maintaining regulatory compliance in plastic packaging manufacturing.

Key standards include ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 45001 (Health and Safety), ISO 22000 (Food Safety), and ISO 15378 (Pharmaceutical Packaging).

The timeline varies based on the size of the organization and its readiness. Typically, it can take several months, including audits and documentation reviews.

Yes, ISO 14001 specifically focuses on environmental management, helping organizations reduce their carbon footprint and manage waste effectively.

Industries such as food, pharmaceuticals, cosmetics, and consumer goods benefit from ISO-certified plastic packaging, ensuring safety and compliance.

Pacific Certifications offers auditing and certification services, helping manufacturers achieve compliance with ISO standards while enhancing operational excellence.

Read More at: Blogs by Pacific Certifications