ISO Certifications for Metal Furniture Manufacturing Businesses, Requirements and Benefits

In a competitive market, ensuring your metal furniture manufacturing processes meet global standards is essential for quality and sustainability. ISO certifications provide a framework to achieve this excellence. By implementing these international standards, manufacturers can not only improve their operations but also gain a international recognition in a global market.

Metal furniture manufacturers operate in an industry where precision, durability, and safety are important. ISO standards are internationally recognized guidelines that help businesses establish robust processes, achieve high-quality production, and comply with legal and environmental requirements.

For metal furniture manufacturing, these certifications align processes with best practices, enhance operational efficiency, and reassure customers of the quality and safety of products. From materials sourcing to final assembly, ISO standards guide every aspect of the business.

If you’re seeking ISO certification for metal furniture manufacturing, reach out to us at support@pacificcert.com or call us at +91-8595603096.

Applicable ISO Standards for Metal Furniture Manufacturing

Several ISO standards are relevant to metal furniture manufacturing. Below are the key certifications to consider:

ISO 9001: Quality Management System: This standard ensures that a company delivers consistent quality by defining a quality management framework. For metal furniture manufacturers, it emphasizes customer satisfaction, process efficiency, and continual improvement.

ISO 14001: Environmental Management System: As environmental concerns grow, ISO 14001 helps manufacturers reduce their environmental footprint. This certification focuses on efficient use of resources, waste management, and compliance with environmental regulations.

ISO 45001: Occupational Health and Safety: This standard is crucial in manufacturing environments where worker safety is a priority. It helps businesses identify and mitigate risks, ensuring safer workplaces for employees.

ISO 3834: Quality Requirements for Welding: For metal furniture requiring welding, ISO 3834 ensures high-quality welding processes. It addresses material selection, welding practices, and testing to guarantee product durability and safety.

ISO 28001: Supply Chain Security: This standard focuses on securing supply chains, ensuring that materials and components are sourced and transported safely. It helps mitigate risks such as theft or delays, which are crucial in maintaining consistent production.

ISO 19650: Building Information Modeling (BIM): For manufacturers involved in projects requiring advanced designs or custom solutions, ISO 19650 ensures structured information management in construction and design processes.

ISO 50001: Energy Management System: For manufacturers aiming to optimize energy consumption, this certification aids in reducing energy costs and enhancing sustainability.

Click here to find out more applicable standards to your industry

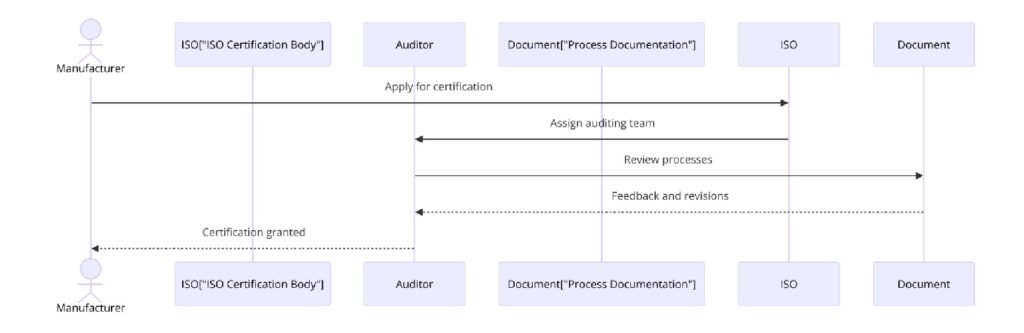

Pacific Certifications specializes in conducting audits and issuing certifications for metal furniture manufacturers seeking to align with ISO standards. Our team of skilled auditors evaluates your processes against the specified standard’s requirements, ensuring compliance and a smooth certification process.

We are dedicated to helping you achieve ISO certifications seamlessly. Our rigorous auditing practices not only validate your compliance but also build credibility with your stakeholders.

Your Trusted Partner in ISO Certification: For expert auditing and ISO certification in metal furniture manufacturing, email us at support@pacificcert.com or call +91-8595603096.

Requirements of ISO Certifications for Metal Furniture Manufacturing

Each ISO standard has specific requirements, and understanding them is critical for successful implementation:

For ISO 9001

- Establish a quality policy that aligns with business objectives.

- Conduct regular internal audits and management reviews.

- Implement customer feedback systems to drive improvements.

For ISO 14001

- Assess environmental aspects and impacts of manufacturing.

- Develop and maintain an environmental policy.

- Set measurable goals for reducing emissions, waste, and resource consumption.

For ISO 45001

- Identify workplace hazards and implement safety controls.

- Provide employee training on safety protocols.

- Regularly monitor and review occupational health and safety performance.

For ISO 3834

- Maintain proper documentation of welding procedures.

- Ensure welders are qualified to perform specific tasks.

- Conduct inspections and tests to verify welding quality.

For ISO 50001

- Monitor energy usage and identify opportunities for optimization.

- Establish an energy management team to oversee improvements.

- Regularly report on energy performance metrics.

Simplify Your Certification Process: Connect with Pacific Certifications via support@pacificcert.com or phone us at +91-8595603096 to get certified quickly and effectively.

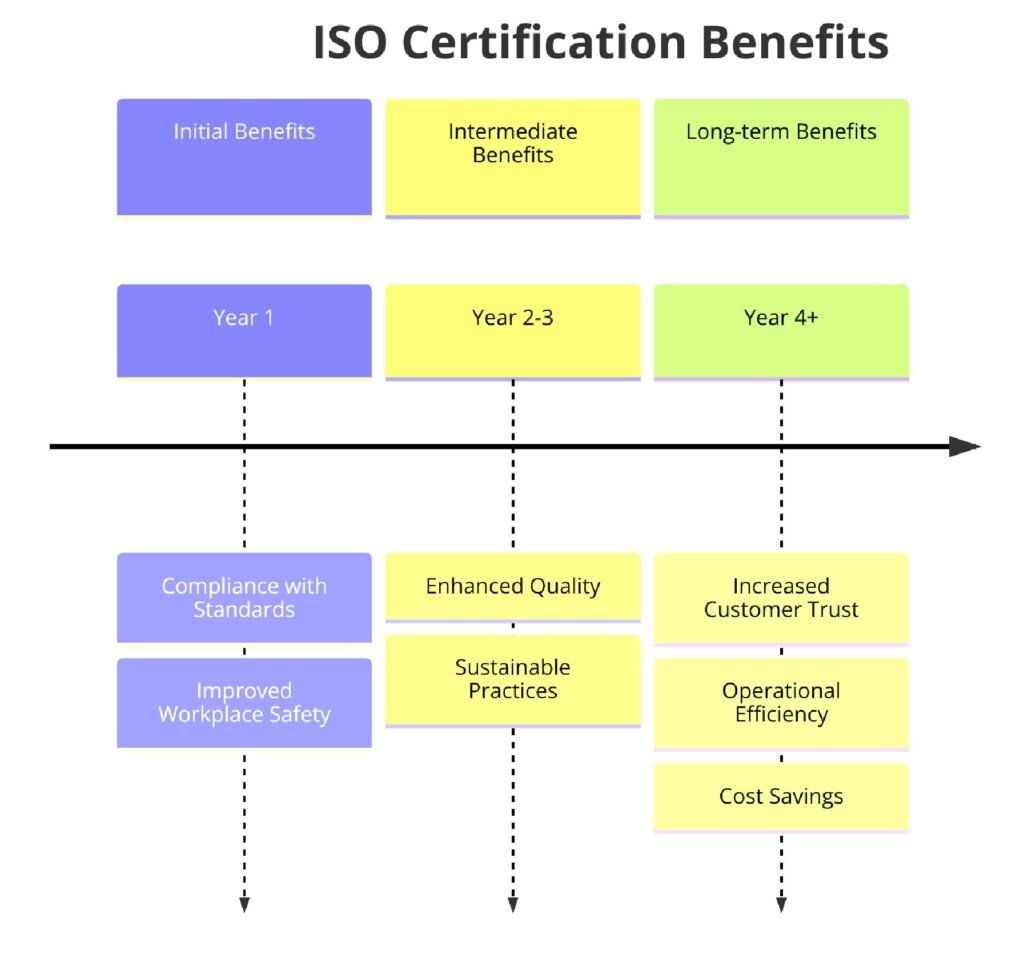

Benefits of ISO Certifications for Metal Furniture Manufacturing

Adopting ISO standards brings multiple benefits to metal furniture manufacturers:

Product Quality: ISO standards ensure that manufacturing processes produce high-quality, durable furniture that meets customer expectations.

Market Reputation: Certifications signal to customers and partners that the business adheres to internationally recognized practices.

Regulatory Compliance: ISO standards help manufacturers comply with local and international regulations, minimizing legal risks.

Efficiency: Streamlined processes, waste reduction, and energy savings are direct outcomes of adopting ISO standards.

Worker Safety: Implementing ISO 45001 reduces workplace hazards, fostering a safer and more productive work environment.

Sustainability and Environmental Responsibility: By adopting ISO 14001 and ISO 50001, businesses demonstrate commitment to sustainability, which resonates with environmentally conscious consumers.

Global Market Access: Many countries and businesses require ISO-certified suppliers, opening doors to new markets and opportunities.

The metal furniture industry is evolving with advancements in automation, sustainable materials, and energy-efficient practices. According to a 2024 market analysis, the demand for eco-friendly and ergonomically designed furniture is driving manufacturers to adopt certifications like ISO 14001 and ISO 9001. Additionally, regulatory frameworks are tightening globally, making ISO certifications not just an advantage but a necessity for sustained business growth.

Are you ready to enhance your metal furniture manufacturing operations with ISO certifications? Contact Pacific Certifications today to begin your journey toward compliance and excellence. Our team is here to guide you through the certification process efficiently and professionally.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Metal Furniture Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Metal Furniture Manufacturing

ISO certifications ensure that manufacturing processes are standardized, resulting in improved quality, operational efficiency, and compliance with international standards.

ISO 9001, ISO 14001, ISO 45001, ISO 3834, ISO 28001, and ISO 50001 are some of the key standards applicable to the industry.

ISO 14001 helps businesses minimize their environmental impact by improving resource efficiency, managing waste, and complying with environmental regulations.

No, Pacific Certifications focuses exclusively on audits and certification issuance. For training or implementation, businesses must seek external consultants.

The timeline varies depending on the organization’s size, processes, and readiness. On average, it can take anywhere from a few weeks to several months.

Costs depend on the standard, the complexity of the manufacturing process, and the size of the organization. Contact Pacific Certifications for a tailored quote.

Read More at: Blogs by Pacific Certifications