What is ISO 3006:2015?

ISO 3006 specifies the design and testing requirements for passenger car wheels used on public roads. The standard ensures that these components are safe, reliable and capable of withstanding various stresses encountered during regular driving. By aligning production and testing practices to ISO 3006 manufacturers reduce the likelihood of wheel failures and improve vehicle safety standards globally.

For companies involved in automotive manufacturing or wheel production, this certification offers an internationally recognized validation of product integrity. It also allows automotive brands to meet legal and contractual expectations in markets where wheel safety is closely monitored.

To begin the ISO 3006 certification process or speak with our audit team, contact us at support@pacificcert.com

What is the purpose of ISO 3006?

The primary purpose of ISO 3006 is to provide standardized safety guidelines for the structural integrity of wheels fitted to passenger vehicles. The standard covers testing methods that assess how a wheel responds to fatigue and impact or even loading conditions under normal road usage. These guidelines reduce the chances of wheel-related accidents and support consistent product quality across manufacturers and markets.

ISO 3006 also supports automotive OEMs and aftermarket suppliers by giving them clear parameters to test new wheel models before entering production or distribution. It helps reduce product recalls and simplifies compliance with import or market-entry requirements in safety-conscious regions.

Scope and Applicability

ISO 3006 applies specifically to wheels intended for passenger vehicles used on paved or maintained public roads. The standard outlines specifications for wheels regardless of their material — whether steel, aluminum alloy, or other metals — as long as they meet the design and performance expectations of standard road vehicles.

The scope includes:

- Original Equipment Manufacturer (OEM) wheels and aftermarket wheels

- Load-carrying components such as rims and discs

- Wheels used under normal driving loads and speeds

- Testing protocols for fatigue, impact, and dynamic performance

It does not apply to off-road wheels, racing wheels, or wheels used in agricultural or industrial vehicles. These applications fall under separate standards tailored for extreme or specialized use cases.

Clause-wise Structure of ISO 3006:2015

Clause | Title | Description |

1 | Scope | Describes the types of wheels and vehicles covered |

2 | Normative References | Lists other standards referred to in ISO 3006 |

3 | Terms and Definitions | Defines technical terms used throughout the standard |

4 | Requirements | Specifies general design and performance guidelines |

5 | Test Methods | Provides detailed procedures for dynamic cornering fatigue and impact tests |

6 | Marking | Covers labeling requirements for traceability and identification |

7 | Information to be Supplied | States what information manufacturers must provide for assessment |

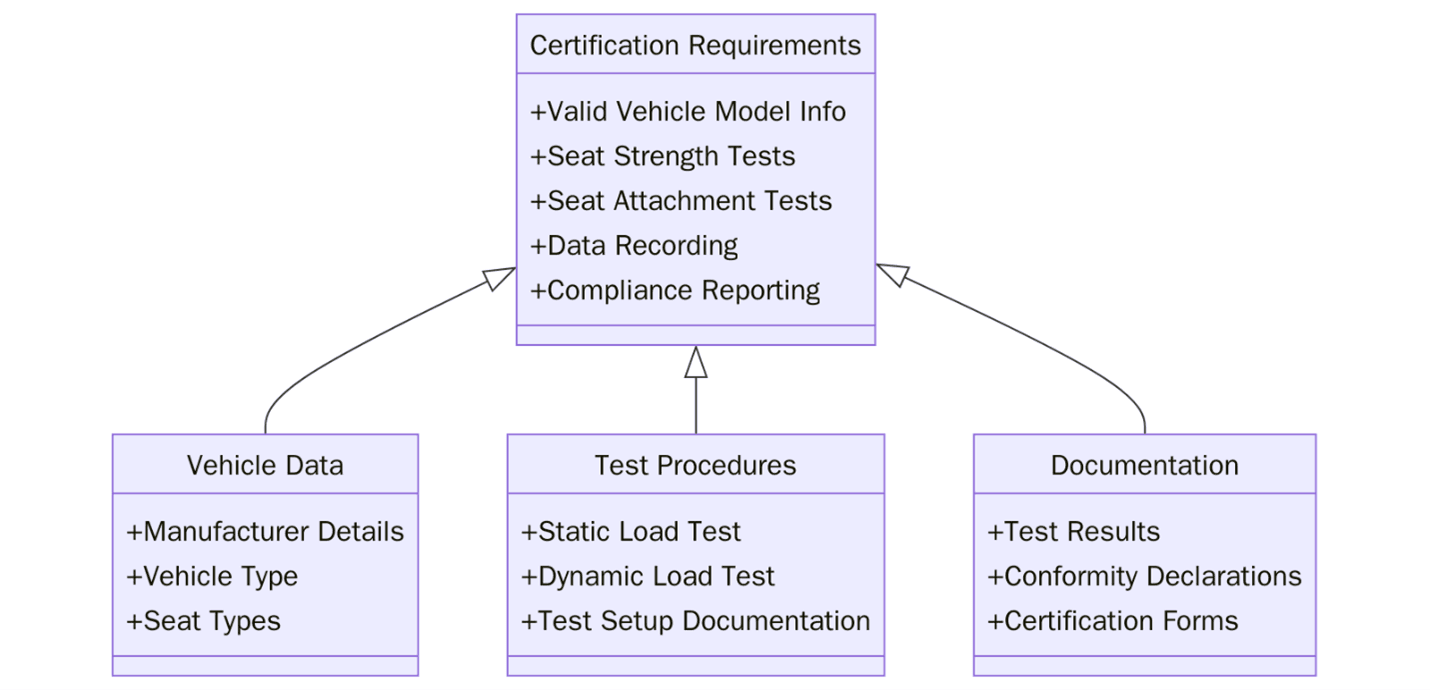

What are the requirements of ISO 3006:2015 Certification?

Before applying for ISO 3006 certification, wheel manufacturers need to ensure their products meet the full set of performance and documentation requirements. These cover structural integrity, identification, and testing capabilities. Below are the key requirements:

- Wheels must pass a dynamic cornering fatigue test under specified load cycles.

- Impact testing must be carried out using a free-falling mass in simulated real-world scenarios.

- Radial fatigue testing is required to simulate continuous vehicle weight and rotation stresses.

- Wheels must be marked clearly with model ID, manufacturer name, load capacity, and date of manufacture.

- All tests must be repeated for wheels of different sizes or construction types.

- Test samples must reflect actual production models, not prototypes made with altered materials.

- Manufacturers must submit complete documentation, including CAD drawings, material composition, and test data.

- Wheels must not exhibit visible cracks, permanent deformation, or detachment of components during any stage of testing.

- Welding joints and fasteners used in two-piece or three-piece wheels must be tested and verified as part of the structural integrity evaluation.

What are the benefits of ISO 3006:2015 Certification?

Certification to ISO 3006 allows organizations to improve product trust and meet international safety expectations. Below are the key benefits:

- Confirms wheel durability under cornering, radial, and impact stresses

- Helps automotive suppliers meet procurement criteria of global OEMs

- Reduces the risk of on-road failures due to material or structural fatigue

- Assists in reducing liability for defects or accidents tied to wheel damage

- Simplifies entry into highly regulated automotive markets such as the EU and Japan

- Gives buyers confidence in the quality of aftermarket wheel replacements

- Promotes consistent wheel performance across different production batches

- Helps manufacturers avoid costly recalls by identifying failures during pre-market testing

- Adds value to brand reputation by supporting vehicle safety claims with verified data

Electric vehicles which exert different load and torque patterns, have also contributed to a shift toward testing frameworks that mirror ISO 3006. As more consumers buy aftermarket or customized wheels, enforcement of durability standards has grown within national vehicle type-approval systems.

Eligibility Criteria

Any company engaged in the design, manufacture, or distribution of passenger car wheels is eligible to apply for ISO 3006 certification. This includes OEMs, suppliers, and third-party testing firms. However, wheels submitted for testing must be production-grade units — not modified or experimental versions.

To qualify, applicants should also maintain traceable records of the manufacturing process, material sourcing, and quality control history for each wheel model.

Certification Process

At Pacific Certifications, the ISO 3006 certification process includes technical reviews, laboratory coordination, and optional facility audits. Here is a simplified breakdown:

- Identify wheel types and variations requiring certification.

- Gather technical drawings, material specs, and prior test results.

- Submit samples for dynamic cornering, radial fatigue, and impact testing.

- Review test data for conformity to ISO 3006 tolerance limits.

- Conduct Stage 1 audit to assess documentation and traceability.

- Perform optional Stage 2 audit to inspect on-site production consistency.

- Receive certification for compliant wheel models.

Timeline for ISO 3006 Certification

The certification process usually takes six to eight weeks. This timeline may vary based on the number of wheel types submitted, test lab scheduling, and whether optional audits are conducted. Wheels requiring additional testing or those with structural changes may extend the timeline by one to two weeks.

What is the Cost for ISO 3006 Certification?

Costs for ISO 3006 certification depend on several factors such as the number of wheel models submitted, the diversity of materials used, and the types of tests required. More variations in rim size, spoke design, or casting method will likely increase the total cost due to repeated test cycles. Companies that bundle ISO 3006 with ISO 9001 audits for quality management may be eligible for discounted pricing.

How can Pacific Certifications Help?

Pacific Certifications supports wheel manufacturers and suppliers with ISO 3006 certification through:

- Guidance on selecting representative test samples

- Help with preparing documentation and engineering drawings

- Coordination with accredited test laboratories

- Review of marking and labeling for traceability

- Audit scheduling and compliance reporting

- Integration with ISO 9001 audits if needed

Training and Courses

Pacific Certifications offers the following training programs for quality engineers, product developers, and compliance teams:

Lead Auditor Training: For professionals conducting supplier audits or internal assessments related to ISO 3006.

Lead Implementer Training: Aimed at engineering teams managing product lifecycle and test documentation for wheel manufacturing.

Internal Auditor Training: Designed for quality control personnel responsible for ongoing monitoring and ISO preparation.

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 3006 training, our team is equipped to help you. Contact us at support@pacificcert.com

FAQs

What does ISO 3006 test for in passenger car wheels?

It focuses on structural durability under cornering, radial, and impact loads to simulate real-world road conditions.

Is ISO 3006 mandatory for wheel sales?

While not always mandatory, many OEMs and regulatory bodies require ISO 3006 testing as part of quality validation.

Can aluminum alloy wheels be certified under ISO 3006?

Yes, ISO 3006 applies to wheels made of steel, aluminum, or any other material that meets its design and performance criteria.

What is the difference between ISO 3006 and DOT standards?

ISO 3006 is an international standard, while DOT standards apply to vehicles in the United States. Both may be required depending on the market.

How often should wheels be retested?

If there are changes in design, materials, or manufacturing process, retesting is recommended. Regular re-certification ensures continuous reliability.

Are aftermarket wheels covered by ISO 3006?

Yes, as long as they are designed for passenger cars and used on public roads, aftermarket wheels fall within the scope of ISO 3006.

Do wheels need to be marked after certification?

Yes, markings must include the manufacturer, model code, date, load index, and any other identifiers specified in the standard.

What happens if a wheel fails the ISO 3006 test?

The wheel must be re-engineered or modified before resubmission. Certification is only granted after passing all required tests.

Ready to get ISO 3006:2015 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs