What is ISO 11960?

ISO 11960 is an international standard that specifies the requirements for steel pipes used as casing or tubing in wells for the petroleum and natural gas industries. These pipes are crucial for drilling operations as they provide structural integrity to wells, protecting the wellbore from collapse and preventing fluid leaks. The standard sets the criteria for the design, materials, manufacturing, testing, and performance requirements to ensure the safe and effective use of steel pipes in these high-pressure environments.

The standard also covers the technical aspects of the pipes’ resistance to corrosion, mechanical strength, and durability, ensuring that they can withstand harsh conditions encountered during drilling and production operations.

For more information, contact us at support@pacificcert.com.

Purpose

The purpose of ISO 11960:2020 is to establish a standardized set of guidelines for manufacturing, testing, and using steel pipes as casing or tubing in oil and gas wells. By following this standard, organizations ensure that the pipes meet the necessary safety, quality, and performance criteria required for their intended use. ISO 11960 provides assurance to operators that the pipes used in well construction will perform reliably under challenging conditions, reducing the risk of well failures and upgrading operational safety.

Scope and Applicability

ISO 11960:2020 applies to steel pipes used for casing and tubing in wells within the petroleum and natural gas industries. The standard is relevant to all organizations involved in drilling, well construction, and production operations, including pipe manufacturers, suppliers, and end users. It is particularly important in sectors where high-pressure, high-temperature, or corrosive conditions are common, such as offshore drilling, deepwater drilling, and unconventional oil and gas exploration. The standard also applies to different pipe grades and connections, ensuring consistency and safety across all drilling operations.

Key Definitions

- Casing: A series of pipes that are inserted into the wellbore to provide structural integrity and prevent the wellbore from collapsing.

- Tubing: A pipe used to transport oil or gas from the reservoir to the surface.

- Steel Pipe: A cylindrical section of steel used to construct casing or tubing that provides mechanical strength and resistance to corrosion.

- Corrosion Resistance: The ability of the steel pipe to withstand degradation caused by the surrounding environment, particularly chemicals or high salinity in the wellbore.

- Pressure Rating: The maximum internal pressure that the steel pipe can safely withstand without failing.

Clause-wise structure of ISO 11960

Clause Number | Title | Description |

Clause 1 | Scope | Defines the scope of the standard, specifying the types of steel pipes covered. |

Clause 2 | Normative References | Lists the standards and documents referenced in ISO 11960. |

Clause 3 | Terms and Definitions | Provides key terms and definitions to ensure consistency and clarity. |

Clause 4 | General Requirements | Details the general requirements for steel pipes, including materials, dimensions, and strength. |

Clause 5 | Material Requirements | Specifies the material properties required for steel pipes used in casing and tubing. |

Clause 6 | Manufacturing Process | Describes the manufacturing methods, quality controls, and tests required for producing steel pipes. |

Clause 7 | Performance and Testing | Outlines the performance tests required to verify the strength, durability, and suitability of the pipes for their intended use. |

Clause 8 | Packaging and Marking | Specifies the packaging, labelling, and marking requirements for steel pipes. |

Clause 9 | Compliance and Certification | Details the process for certifying the compliance of steel pipes with the standard. |

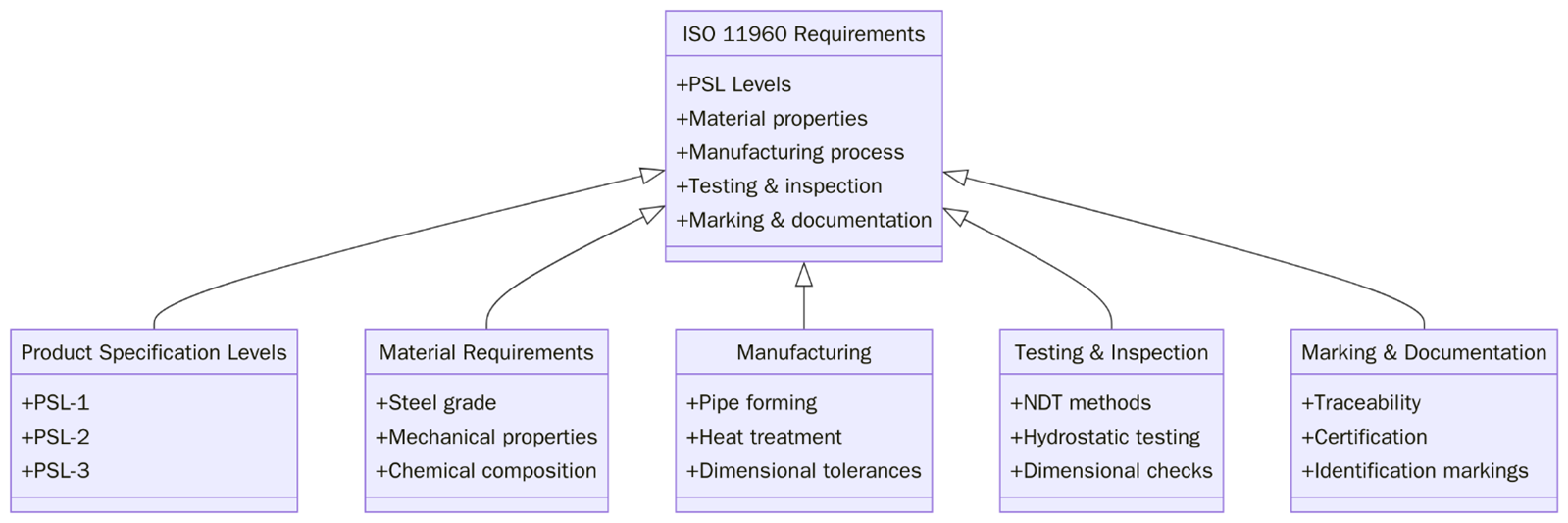

What are the requirements of ISO 11960?

ISO 11960 outlines several important requirements for steel pipes used as casing or tubing in wells.

It specifies a comprehensive set of guidelines to ensure the safe and reliable use of steel pipes in well construction. The standard provides detailed criteria for material properties, manufacturing practices, and testing to ensure that pipes meet operational demands and environmental conditions. Below are the key requirements:

- The steel used for casing and tubing must meet specific mechanical properties, such as tensile strength, yield strength, and resistance to corrosion.

- Pipes must be manufactured according to specified processes that ensure uniformity, integrity, and reliability.

- Steel pipes must undergo a series of tests to verify their performance under pressure and temperature conditions typical of well environments. Tests may include burst tests, collapse tests, and internal pressure tests.

- The pipes must meet specified dimensional standards, including wall thickness, length, and diameter, to ensure proper fit and functionality.

- A strong quality assurance process must be in place, including periodic inspections and documentation of the manufacturing process.

For more information, contact us at support@pacificcert.com.

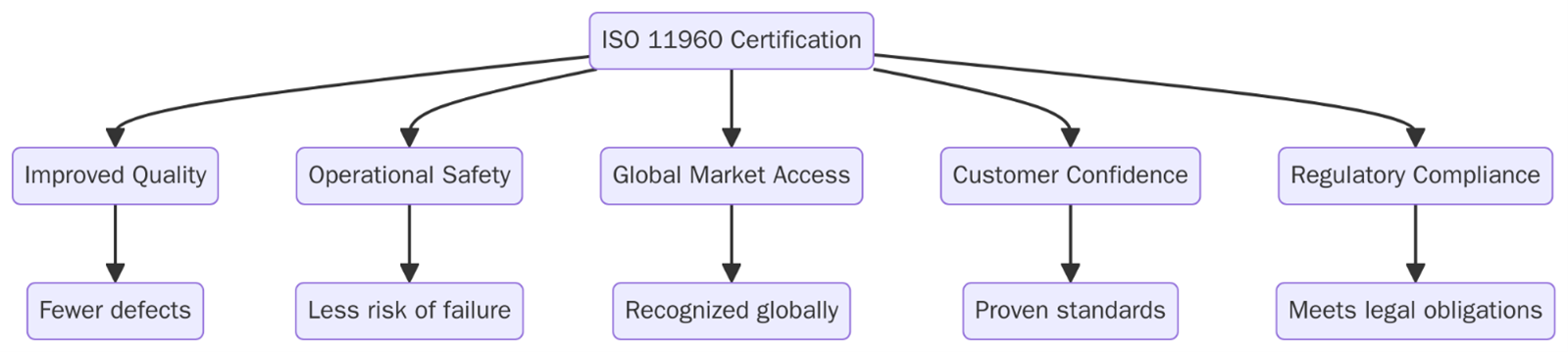

What are the benefits of ISO 11960 Certification?

ISO 11960 certification offers several key benefits for organizations involved in the petroleum and natural gas industries.

ISO 11960 certification provides organizations with a structured framework to ensure the safety, reliability, and compliance of steel pipes used in casing and tubing. By meeting the requirements of the standard, organizations can improve the overall quality and performance of their drilling operations. Below are some of the key benefits of obtaining ISO 11960 certification:

- Certification ensures that steel pipes meet stringent material, manufacturing, and performance requirements, improving the overall quality of the product.

- By adhering, organizations can minimize the risk of well failures or accidents due to defective pipes.

- Achieving certification helps organizations comply with industry regulations and standards related to well construction and safety.

- Certification upgrades the credibility of manufacturers and suppliers, showing their commitment to quality and safety.

As the demand for oil and gas continues to grow globally, the need for high-quality, reliable casing and tubing materials will become even more critical. In the recent years, the oil and gas industry is expected to place a stronger emphasis on compliance with international standards like ISO 11960 to ensure safety, quality, and environmental sustainability. Companies that are ISO 11960 certified will be better positioned to meet these growing demands and secure contracts in global markets.

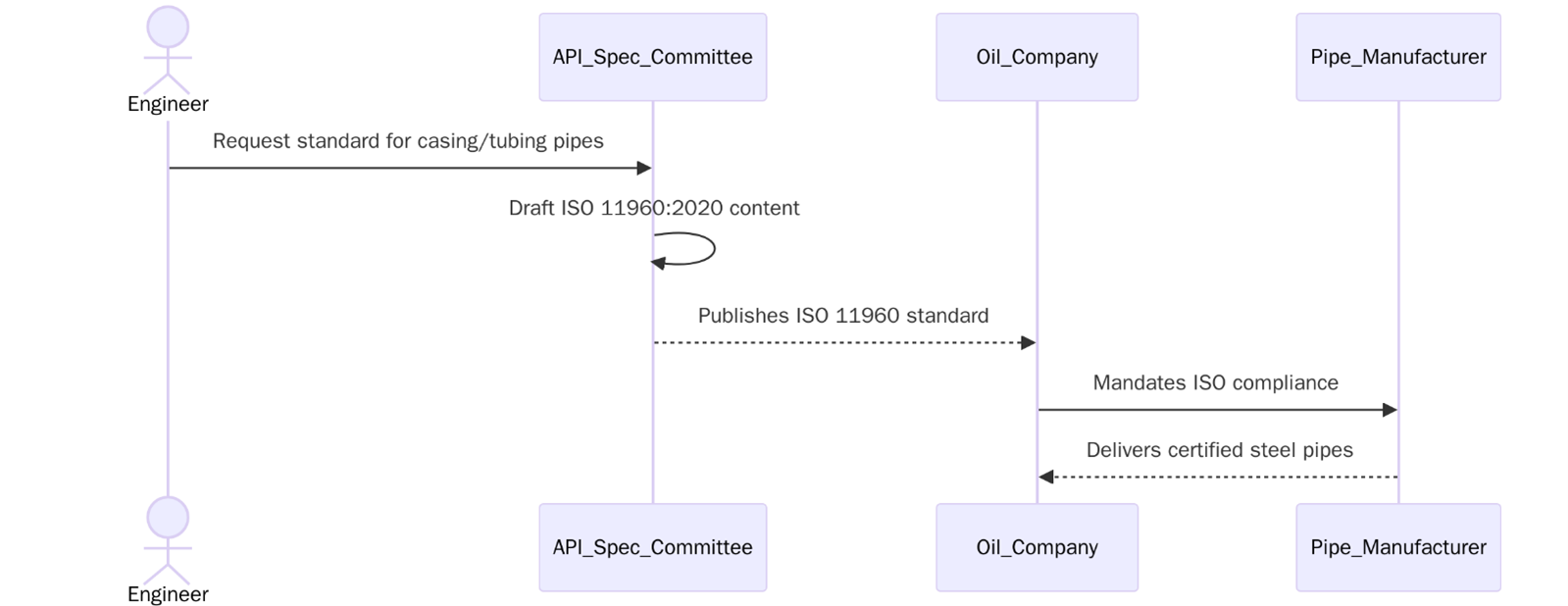

Certification Process

The certification process for ISO 11960 typically includes the following steps:

- Pre-Certification Assessment: Conducting a gap analysis to identify areas for improvement in the manufacturing and testing processes.

- Documentation Review: Reviewing existing documentation to ensure that the organization meets the standard’s requirements for material properties, testing, and manufacturing.

- Stage 1 Audit: A preliminary audit to assess the organization’s readiness for certification and verify initial compliance with the standard.

- Stage 2 Audit: A detailed on-site audit to evaluate the implementation of processes, manufacturing techniques, and testing protocols.

- Certification Decision: Certification is awarded if all requirements are met and the company shows compliance with ISO 11960.

- Ongoing Monitoring: Regular audits and recertification ensure that the organization continues to meet the standard’s requirements.

Timeline for ISO 11960 Certification

The timeline for ISO 11960 certification generally spans several months. The pre-assessment and preparation phase takes around 1-2 months, during which the organization reviews its current risk management processes. The Stage 1 audit generally lasts about 1 month. The Stage 2 audit, which involves a comprehensive review of processes and testing procedures, takes 1-2 months. Certification issuance happens within 3-6 months, depending on the audit findings and the organization’s readiness for certification.

What is the Cost?

The cost of ISO 11960 certification can vary depending on factors such as the size of the organization, the complexity of its operations, and the number of pipes manufactured. Typical costs include:

Audit Fees is the fees for the certification body’s audit process. Training Costs are the Costs for educating staff on this standard and the necessary processes to comply with the standard. Ongoing Maintenance is the Regular audits and recertification, typically required every 3 years.

How Pacific Certifications Can Help?

At Pacific Certifications, we provide comprehensive auditing and certification services for ISO 11960. Our team will guide you through the entire certification process, ensuring that your organization complies with the highest standards for casing and tubing pipes. Our services include:

- Stage 1 and Stage 2 audits to evaluate the manufacturing and testing processes.

- Objective conformity assessments based on ISO 11960.

- Certification issuance upon successful completion of the audit.

- Ongoing surveillance audits to ensure continued compliance.

- Support for multi-site or global operations.

For audits and certification, contact support@pacificcert.com.

ISO 11960 Training and Courses

Various training courses are available to help organizations comply with ISO standards, including:

- Lead Auditor Training – Equips professionals to conduct external third-party audits.

- Lead Implementer Training – For those responsible for planning and executing ISO 11960 implementation.

- Internal Auditor Training – Preparing internal auditors for certification audits

Pacific Certifications provides accredited training programs. If your organization is looking for ISO 11960 training, our team is equipped to help you.

Frequently Asked Questions (FAQs)

How long does it take to get ISO 11960 certification?

The certification process typically takes 3–6 months, depending on your organization’s preparedness and audit outcomes.

Is ISO 11960 certification mandatory for all casing and tubing manufacturers?

While it is not legally required, ISO 11960 certification is essential for ensuring the quality and safety of steel pipes used in well construction, enhancing credibility and compliance.

What are the main benefits of ISO 11960 certification?

Certification ensures compliance with international safety and quality standards, improves product reliability, and boosts customer confidence.

Can I apply for ISO 11960 certification without a quality management system in place?

No, a quality management system is necessary before applying for certification.

How often do I need to renew ISO 11960 certification?

ISO 11960 certification is valid for three years, after which recertification is required

Ready to get ISO 11960 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs