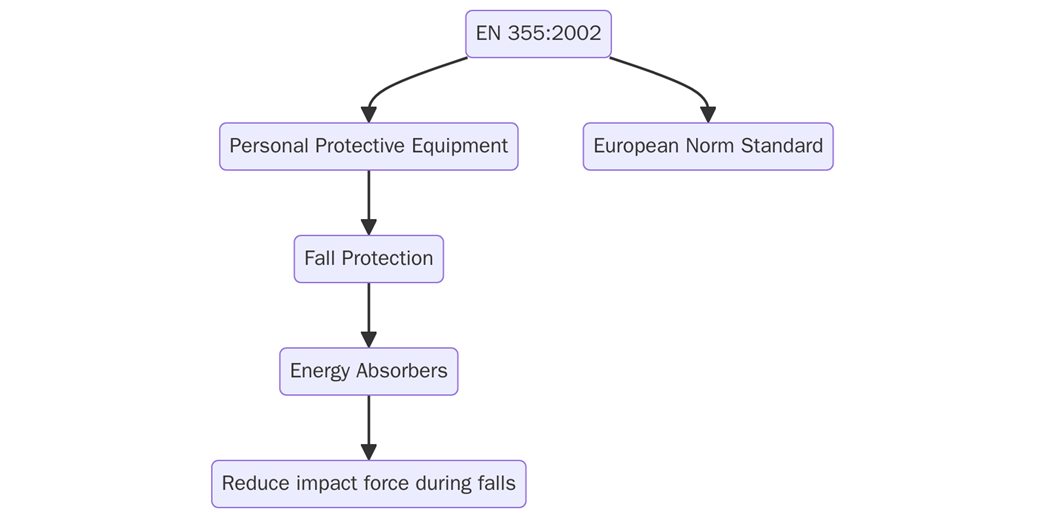

What is EN 355:2002?

EN 355:2002 sets the European standard for energy absorbers, a critical component of personal protective equipment (PPE) used in fall arrest systems. It outlines the requirements for performance, design, testing, and marking to ensure that lanyards equipped with energy absorbers effectively limit the forces transmitted to the human body during a fall from height.

Falls from height remain one of the leading causes of workplace accidents worldwide. According to EU safety statistics, they account for nearly one-third of fatalities in construction and maintenance sectors. EN 355:2002 was introduced to harmonize safety expectations across Europe, offering workers dependable protection and giving employers a standardized benchmark for compliance.

To know how your organization can align with EN 355:2002 and strengthen fall protection practices, contact support@pacificcert.com.

Purpose

The purpose of EN 355:2002 is to reduce the risks associated with falls by providing clear guidelines on how energy absorbers should perform in real fall scenarios. Unlike standard lanyards that may transmit unsafe levels of impact, energy absorbers designed under EN 355 deploy in a controlled way to dissipate kinetic energy. This ensures that workers are not exposed to shock loads beyond human tolerance levels.

By establishing uniform requirements, EN 355 helps manufacturers design safer products and gives employers confidence when selecting fall arrest systems. Its ultimate objective is to safeguard workers’ lives while minimizing injuries and ensuring compliance with European PPE directives.

Scope and Applicability

EN 355:2002 applies specifically to energy absorbers used in personal fall arrest systems, whether they are standalone devices or integrated into lanyards or lifelines. The standard sets performance requirements for dynamic and static testing, durability, material resistance, marking and user instructions. It is relevant for industries where working at height is frequent, including construction, utilities, telecommunications, industrial maintenance and oil and gas operations. Beyond Europe, EN 355:2002 is widely recognized globally as a benchmark for safety, helping manufacturers gain international market acceptance. Organizations using EN 355-compliant equipment can reduce workplace hazards, improve compliance with occupational health and safety guidelines and improve employee confidence in their personal protective equipment.

Key Definitions

- Energy Absorber: A device that dissipates energy during a fall to reduce forces on the user.

- Fall Arrest System: Equipment designed to safely stop a falling person.

- Deceleration Force: Maximum force applied to the user during a fall arrest.

- Dynamic Test: Test simulating falls to measure performance.

- Lanyard: Flexible connection line used in fall arrest systems.

Clause-wise Structure

| Clause | Description |

| Scope | Defines objectives, boundaries, and intended application of the standard. |

| Normative References | Lists important referenced documents necessary for correct implementation. |

| Terms and Definitions | Standardizes terminology to ensure clear communication. |

| Requirements | Specifies performance, materials, design, and functional criteria. |

| Testing | Outlines dynamic and static tests to verify safety under fall conditions. |

| Marking and Instructions | Specifies labelling requirements and necessary user guidance. |

| Information for Users | Provides instructions on installation, inspection, maintenance, and replacement. |

| Additional Requirements | Covers optional features and environmental considerations. |

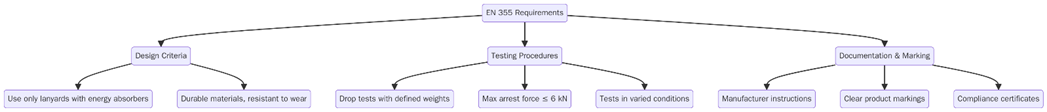

What are the EN 355:2002 requirements?

Before listing the requirements, it is important to understand that energy absorbers must not only meet mechanical and material specifications but also ensure practical safety in real-world operations. They are designed to reduce the forces experienced by workers in dynamic falls while remaining durable and easy to use. Organizations and manufacturers must evaluate the complete lifecycle of the absorber from material selection to labelling and user instructions. Below are some of the key requirements:

- The maximum impact force on the user must be limited, generally not exceeding 6 kN, to prevent injuries.

- Materials must be resistant to wear, UV, moisture and chemical exposure to maintain integrity over time.

- Connection interfaces must be compatible with harnesses, connectors, or lanyards used in fall arrest systems.

- Devices must pass dynamic tests simulating falls of various heights and user weights.

- Components must withstand static strength tests without failure under expected loads.

- Products must be clearly labelled with manufacturer details, model number, serial number and maximum user load.

- Overreaching user instructions must be provided, including guidance on installation, inspection, and maintenance.

- Absorbers must maintain performance across environmental conditions expected during usage.

- Damaged, worn or improperly maintained absorbers must not be used.

- Documentation must include inspection logs and replacement schedules to ensure ongoing safety.

For more information, contact us at support@pacificcert.com.

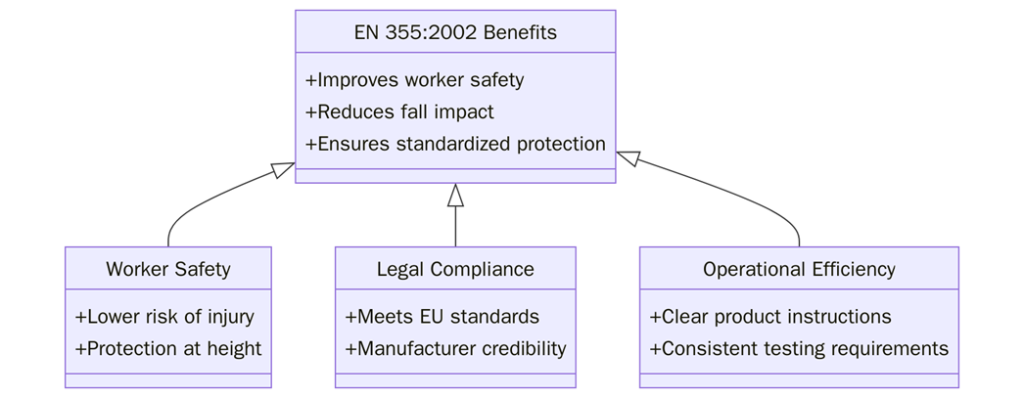

What are the EN 355:2002 benefits?

Using EN 355:2002-compliant energy absorbers provides multiple advantages beyond simple safety. The devices are tested and verified to perform reliably under dynamic conditions, offering predictable protection. Employees gain confidence in their personal protective equipment, while organizations benefit from regulatory alignment, reduced workplace incidents and improved credibility in safety practices. Below are some of the key benefits:

- Limits the forces experienced during falls, reducing the likelihood of serious injuries or fatalities.

- Supports compliance with European and international safety standards, facilitating market acceptance.

- Dynamically tested energy absorbers provide predictable behaviour under various fall scenarios.

- Resistant materials extend the functional life of the equipment, reducing replacements.

- Workers can trust that the equipment will function correctly when needed.

- Compatible with harnesses, lanyards, and lifelines used in fall arrest systems.

- Reduces misuse and ensures proper inspection, installation and maintenance.

- shows a commitment to workplace safety and employee well-being.

- Using EN 355-compliant devices can support claims for workplace insurance and reduce organizational liability.

- Prevents incidents that can disrupt workflows or cause project delays.

The global market for personal fall protection equipment is expanding due to stricter safety regulations, increased construction and infrastructure projects, and growing awareness of occupational hazards. Europe, North America and Asia-Pacific are leading markets, with EN 355-compliant absorbers in high demand for construction, oil and gas, industrial maintenance, and renewable energy sectors. Recent trends include the development of lightweight and ergonomic energy absorbers, integration with digital monitoring systems for real-time inspection and environmentally resistant materials that extend product life. Companies adopting certified equipment gain competitive advantage while ensuring worker safety.

Certification Process for EN 355:2002 Implementation

Implementing EN 355:2002 compliance involves multiple stages. Below is an expanded explanation of the process:

- Initial Gap Assessment: Organizations review existing PPE against EN 355 requirements to identify gaps in compliance. This includes verifying product specifications, labelling and supplier certifications.

- Selection of Equipment: Employers must select energy absorbers tested and certified to EN 355. Manufacturers, on the other hand, must send their products to accredited testing laboratories.

- Testing and Verification: Accredited labs conduct dynamic performance tests, material resistance checks, and deployment length assessments. Manufacturers must document the results.

- Integration into Safety Management Systems: Employers integrate EN 355-compliant equipment into occupational health and safety frameworks, often aligning with ISO 45001.

- Worker Training and Competence: Employees receive training on proper use, inspection, and storage of energy absorbers. Training records must be maintained.

- Third-Party Audits: Independent audits may be conducted to verify compliance, particularly for suppliers to large construction or industrial projects.

- Ongoing Monitoring and Inspections: Employers are responsible for periodic checks, typically every 6 to 12 months, and replacing equipment after any fall event.

- Documentation and Records: Overreaching records of procurement, inspection, and compliance certificates are required to prove alignment with EN 355:2002 during regulatory checks.

What is the EN 355 2002 timeline?

The timeline for achieving EN 355:2002 compliance varies depending on whether you are a manufacturer or an employer. For Manufacturers, the process can take 6 to 12 months, covering product design, lab testing, certification, and labelling. The timeline is longer if prototypes need redesign after initial test. For Employers, Compliance implementation typically takes 2 to 4 months, including procurement of certified PPE, staff training, and integrating procedures into health and safety systems. In large organizations with multiple sites, timelines may extend to 6 months due to logistics and workforce coverage. Compliance does not end after initial adoption. Regular re-certification of products and annual audits for employers are required to maintain compliance.

What is the EN 355 2002 certification cost?

The cost of EN 355:2002 implementation depends on the type of organization and role in the supply chain. Manufacturers face expenses for design, testing in accredited labs, product modifications, certification fees, and marking. These costs can range from moderate to significant depending on product complexity and batch sizes.

For employers, costs include purchasing compliant energy absorbers, conducting training programs, and carrying out third-party inspections. There are also indirect costs such as administrative work for documentation and periodic monitoring. However, organizations often recover these costs through reduced accident rates, lower insurance premiums, and improved market access. Many government projects in Europe require compliance as a precondition for participation, making EN 355 an investment in both safety and competitiveness.

How Pacific Certifications Can Help?

Pacific Certifications assists organizations and manufacturers in aligning with EN 355:2002 through certification support and audits. Our services include:

- Conducting gap assessments to identify compliance gaps.

- Guiding product testing and performance verification.

- Assisting in labelling, documentation, and instruction updates.

- Providing training for staff on use and inspection.

- Integrating compliance into ISO 9001 and other quality management systems.

Contact support@pacificcert.com for guidance.

Training and Courses

Training ensures that EN 355-compliant PPE is used correctly and consistently. Common training includes:

- Lead Auditor Training: Audit compliance of energy absorbers and fall arrest systems.

- Lead Implementer Training: For designing and implementing compliant fall arrest equipment.

- Internal Auditor Training: Assess ongoing compliance and inspection routines.

Pacific Certifications provides accredited training programs. Contact support@pacificcert.com.

Frequently Asked Questions (FAQs)

Is EN 355 certifiable?

No. EN 355 is a performance standard. Compliance is verified through testing.

What industries require EN 355-compliant equipment?

Construction, oil and gas, industrial maintenance, utilities, and telecommunications.

What is the maximum load for EN 355 energy absorbers?

Generally, they limit the impact force to 6 kN depending on user weight and fall height.

How often should energy absorbers be inspected?

Before each use and periodically according to manufacturer guidance.

Can EN 355 absorbers be used in all weather conditions?

Yes, compliant absorbers are designed for durability under expected environmental conditions.

Contact Us

If you need support with EN 355 certification, contact us at support@pacificcert.com.

Read More at: Blogs by Pacific Certifications