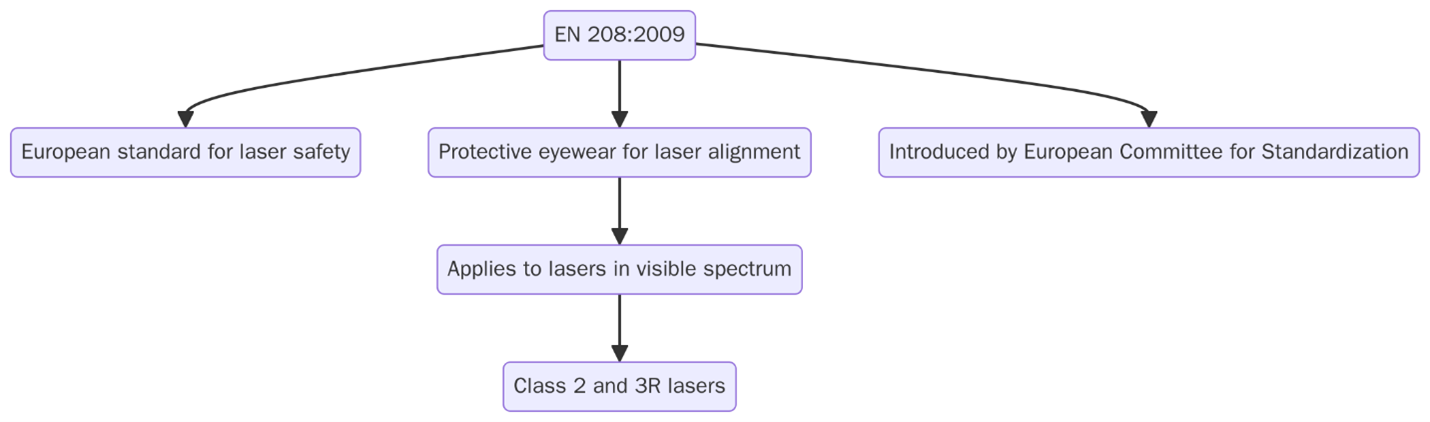

What is EN 208:2009?

EN 208:2009 is a European standard specifying the requirements for eye-protectors used during adjustment work on lasers and laser systems. Unlike protective eyewear designed for permanent laser operation, EN 208 focuses on eyewear that allows visibility of the laser beam while reducing its power to a safe level. This is crucial during alignment and adjustment tasks, where the laser needs to be visible for precise positioning, but the operator’s eyes must still be safeguarded.

The standard applies to various types of laser adjustment eyewear, including filters and frames and outlines criteria for optical density and resistance to mechanical and thermal damage. It ensures that the eyewear provides adequate protection against accidental exposure during these high-risk activities, without hindering visibility needed for alignment.

For audit and certification assistance, contact us at support@pacificcert.com

What is the Purpose EN 208?

The purpose of EN 208 is to provide a defined safety framework for eyewear used in situations where laser alignment and adjustment work is performed. Such tasks are inherently more hazardous than general observation because the operator works directly with an active beam path.

The standard ensures that the protective eyewear attenuates the beam to a safe level without blocking it entirely, allowing the beam to remain visible. This balance between visibility and safety is critical for avoiding accidents and preventing permanent eye injuries.

Scope and Applicability

EN 208 applies to all types of protective eyewear specifically designed for laser adjustment operations. It covers spectacles, goggles, and visors that incorporate special filters meeting the defined transmission and attenuation requirements.

The standard is applicable across industries such as medical laser systems, research laboratories, industrial cutting or welding lasers, and optical equipment servicing. Manufacturers, distributors, and organizations using lasers for maintenance or calibration can apply this standard to ensure the safety of personnel involved in beam alignment tasks.

Key Definitions

- Laser Adjustment Eyewear – Protective eyewear allowing visibility of a laser beam while reducing its intensity to a safe exposure level.

- Optical Density (OD) – The measure of attenuation of laser light passing through the filter.

- Visible Transmission – The percentage of visible light allowed through the filter for operational visibility.

- Beam Attenuation – Reduction in laser energy reaching the eye through the filter material.

- Alignment Work – Activities involving fine positioning, focusing, or calibration of laser beams.

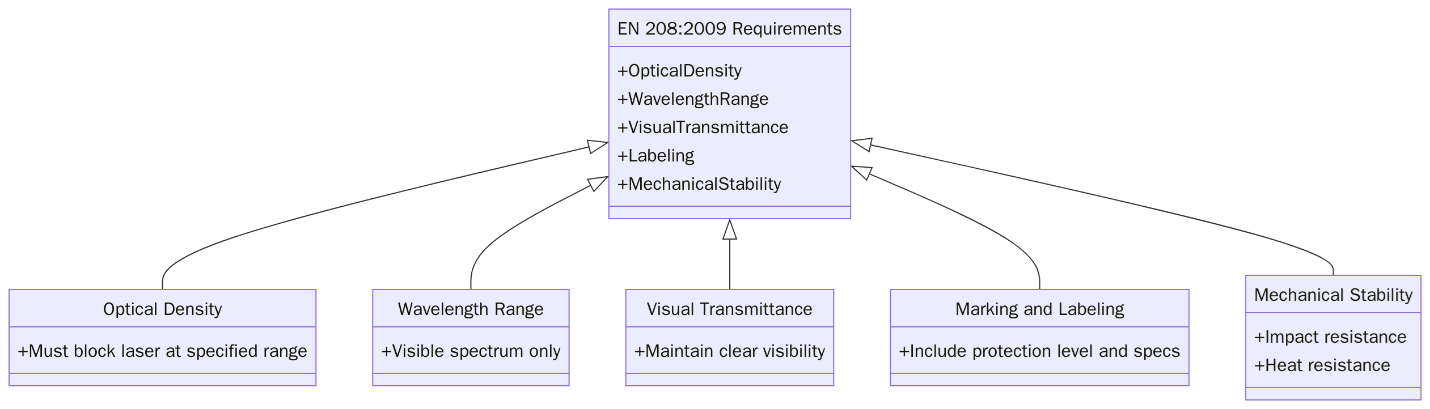

What are the requirements of EN 208:2009?

Before obtaining certification, it is important to understand that EN 208 outlines both optical and physical requirements for laser adjustment eyewear. The eyewear must undergo laboratory testing under specified conditions to verify compliance. Below are some of the key requirements:

- Eyewear must provide adequate beam attenuation at the laser wavelength, reducing irradiance to a level considered safe for the human eye during alignment tasks.

- Filters must maintain visibility of the beam without excessive color distortion.

- Optical density values must match the claimed protection levels stated by the manufacturer.

- Transmission in the visible range must allow sufficient light for accurate beam alignment work.

- Frames and lenses must withstand mechanical impact tests to ensure durability in work environments.

- The eyewear must resist heat and thermal stress from potential laser beam contact.

- Products must be clearly marked with relevant protection specifications, including wavelength range and optical density.

- All components of the eyewear, including frames and coatings, must meet the standard’s safety criteria.

What are the benefits of EN 208:2009?

Meeting the EN 208 requirements provides several advantages for both manufacturers and users. Below are the key benefits:

- Improved eye safety – Reduces risk of permanent vision damage during laser adjustment work.

- Operational efficiency in alignment tasks – Allows workers to see the beam clearly while staying protected.

- International recognition – Helps align with EU workplace safety regulations and ISO-based quality systems.

- User confidence – Ensures eyewear performs reliably under expected laser exposure conditions.

- Reduced liability – Minimizes risks of injury claims by adhering to a recognized safety standard.

- Market access – Enables sales within regions requiring EN-compliant safety equipment.

- Quality assurance – Provides verified product specifications backed by third-party testing.

The demand for EN 208-certified laser adjustment eyewear is growing in line with the rapid adoption of high-powered lasers in sectors such as medical surgery, precision manufacturing, telecommunications and scientific research. With the expansion of laser applications especially in fiber optics and semiconductor production there is heightened awareness about operator safety during beam alignment work.

Eligibility Criteria

Any manufacturer, distributor, or organization producing or using laser adjustment eyewear can seek EN 208 certification. This includes companies supplying eyewear for research facilities, laser manufacturing lines, optical servicing, and medical laser alignment.

There are no restrictions on company size, but the eyewear must be subjected to full third-party laboratory testing to verify compliance with all optical and mechanical requirements.

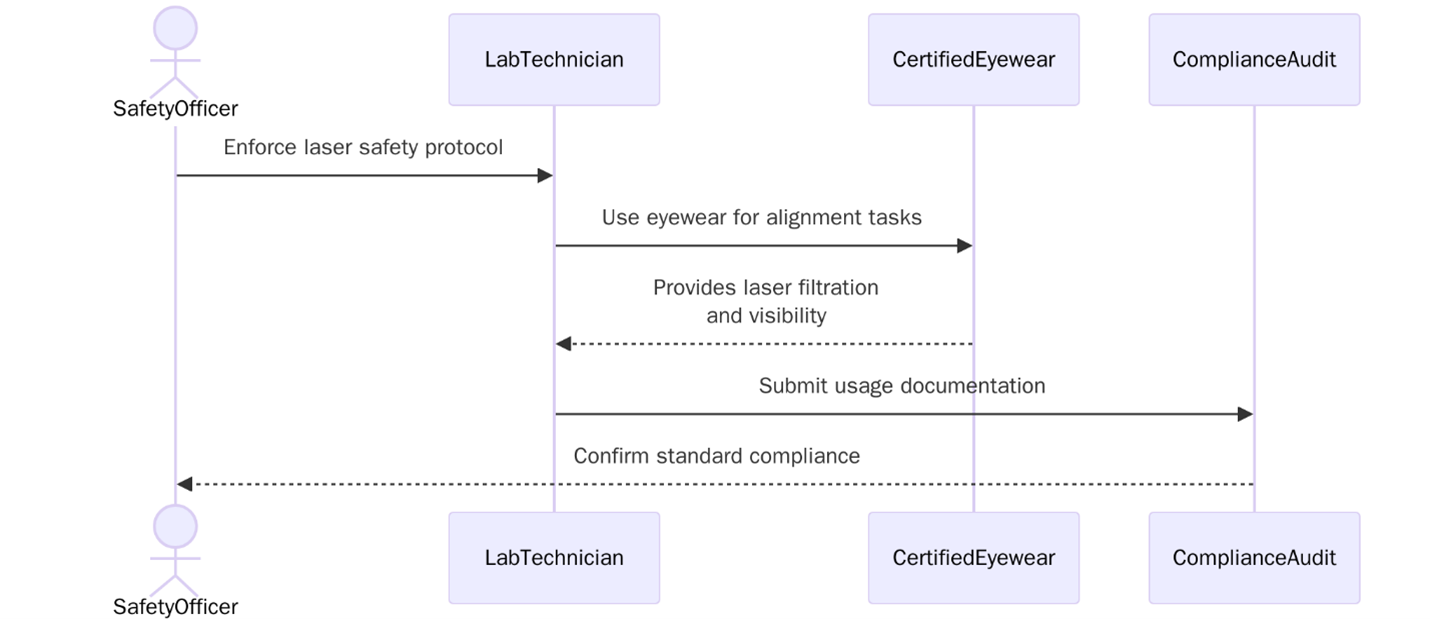

Certification Process: EN 208:2009

Certification for EN 208 typically follows these stages:

- Identify eyewear models for certification – Select the specific products to be tested.

- Review product specifications – Check wavelength ranges, optical densities, and frame construction.

- Conduct laboratory testing – Measure optical transmission, attenuation, and visible light performance.

- Mechanical and thermal testing – Ensure durability under potential workplace hazards.

- Marking and labeling review – Verify protection markings are correct and visible on the product.

- Submit documentation – Provide test reports, technical data sheets, and manufacturing process details.

- Stage 1 audit – Certification body reviews submitted reports and specifications.

- Stage 2 audit – On-site manufacturing and quality assurance evaluation.

- Certification issue – Products receive EN 208 compliance certification.

Timeline for Certification

The EN 208 certification process generally takes between two to three months, depending on the complexity of the eyewear and testing requirements. If the manufacturer already has valid optical test data, the timeline may be shorter. However, products requiring full mechanical, optical, and thermal testing may extend the timeline to four months.

EN 208:2009 Certification Cost

Certification costs vary depending on the number of eyewear models submitted, the range of wavelengths covered, and whether new testing is required. If previous independent testing is available, costs may be reduced. Certification alongside other safety eyewear standards such as EN 207 can also be more cost-effective.

How can Pacific Certifications Help?

Pacific Certifications provides accredited third-party audit and verification services for EN 208 certification. Our services include:

- Reviewing product design and specifications to ensure compliance with EN 208.

- Verifying laboratory test results for optical density, transmittance, and wavelength coverage.

- Checking mechanical and thermal performance against standard requirements.

- Assessing labeling and marking accuracy for traceability.

- Providing bundled certification audits for related standards such as EN 207 or ISO safety eyewear standards.

Our goal is to ensure your laser adjustment eyewear meets EN 208 requirements with full documentation and credible certification.

Training and Courses

- Lead Auditor Training – Focuses on evaluating eyewear for compliance with EN 208, including understanding optical testing and mechanical assessment.

- Lead Implementer Training – Covers integrating EN 208 requirements into eyewear design, production, and quality control systems.

- Internal Auditor Training – Designed for safety officers and quality teams to ensure ongoing compliance in manufacturing and distribution.

Pacific Certifications offers accredited training programs. If your organization is looking for EN 208 training, our team can assist. Contact us at support@pacificcert.com

FAQs

Is EN 208 different from EN 207?

Yes. EN 208 covers eyewear for laser adjustment work, allowing visibility of the beam. EN 207 covers eyewear for full laser protection during operation.

Does EN 208 apply to all laser classes?

It applies mainly to eyewear used with Class 3B and Class 4 lasers during alignment, where beam visibility is needed.

Can I use EN 208 eyewear for normal laser operation?

No. EN 208 eyewear is designed for reduced-power alignment tasks, not for continuous exposure to full-power beams.

Are EN 208 products mandatory in the EU?

They are required when performing laser adjustment tasks where such protection is necessary under workplace safety laws.

How long does EN 208-certified eyewear last?

Lifespan depends on usage, storage, and exposure conditions. Regular inspection is recommended.

Can eyewear be certified if it covers multiple wavelengths?

Yes, as long as it meets attenuation and visibility requirements across all claimed wavelengths.

Is retesting needed if we change the frame but not the filter?

Yes, because EN 208 assesses the complete eyewear, including frame performance.

What testing standards are used for EN 208?

Testing follows specific optical and mechanical methods defined in the standard to verify safety and performance.

Contact Us

If you need support with EN 208 certification, contact us at support@pacificcert.com.

Read More at: Blogs by Pacific Certifications