What is EN 10219-1?

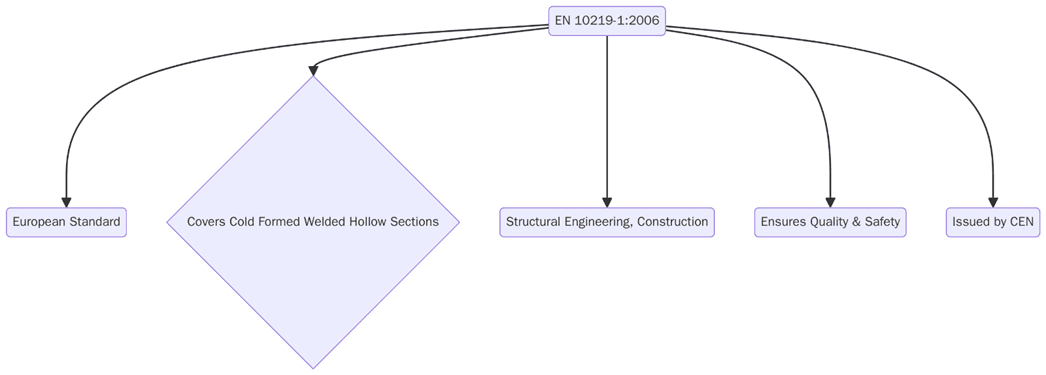

EN 10219-1:2006 is an international standard that specifies the requirements for cold-formed welded structural hollow sections made from non-alloy and fine grain steels. These hollow sections are widely used in construction, infrastructure, industrial frameworks, and engineering applications due to their excellent strength-to-weight ratio and consistent mechanical properties.

The standard ensures uniformity in dimensions, tolerances, mechanical characteristics and weld quality, allowing engineers, fabricators and designers to reliably use these materials in load-bearing structures. Compliance with EN 10219-1 ensures that hollow sections are manufactured with controlled material quality, consistent thickness, and accurate welding procedures, thereby enhancing safety, structural integrity and predictability in construction projects.

To learn more about aligning your structural steel operations with EN 10219-1 standards, contact our team at support@pacificcert.com.

What is the Purpose of EN 10219-1?

The primary purpose of EN 10219-1 is to provide consistent technical requirements for cold-formed welded hollow sections, facilitating their safe and smooth use in construction and industrial applications. Structural hollow sections are often critical load-bearing elements in frameworks, bridges, industrial buildings, and high-rise constructions. The standard establishes minimum mechanical properties, dimensional accuracy, weld quality and testing requirements, which ensures that manufacturers and end-users can trust the performance of the material under load, environmental stress and fabrication processes. By standardising these requirements, EN 10219-1 reduces design uncertainties, improves compatibility with other construction materials and improves overall structural safety. It also supports regulatory compliance, quality management and risk reduction across construction and fabrication projects.

What is the Scope and Applicability of EN 10219-1?

EN 10219-1 applies to cold-formed welded structural hollow sections produced from non-alloy or fine grain steels. It is relevant to manufacturers, construction companies, engineers, fabricators, and quality assurance personnel involved in the production, supply, and application of hollow steel sections. The standard covers round, square, and rectangular cross-sections and applies to sections intended for use in structural load-bearing applications.

It sets requirements for mechanical properties, tolerances, welding quality, testing procedures, and markings. EN 10219-1 is applicable both to new production lines and to quality verification of existing hollow section stocks, ensuring that every section meets consistent structural and safety criteria. The standard also provides a reference for international engineering projects where uniformity, traceability, and reliability of steel sections are critical.

Clause-wise Structure of EN 10219-1

| Clause | Title | Description |

| 1 | Scope | Defines the applicability to cold-formed welded hollow sections and outlines the purpose of standardization. |

| 2 | Normative References | Lists referenced standards related to steel grades, testing methods, and welding practices. |

| 3 | Terms and Definitions | Clarifies terminology such as section type, wall thickness, and weld seam. |

| 4 | Classification | Specifies steel grades, wall thicknesses and section types covered by the standard. |

| 5 | Technical Delivery Conditions | Defines material, dimensional, mechanical and tolerance requirements. |

| 6 | Manufacturing Requirements | Outlines cold forming, welding procedures, heat treatment and quality control processes. |

| 7 | Testing and Inspection | Provides guidelines for mechanical testing, dimensional checks and weld evaluation. |

| 8 | Marking and Documentation | Specifies marking on sections, certification requirements and traceability documentation. |

| 9 | Compliance and Verification | Details inspection and verification procedures for manufacturers and independent bodies. |

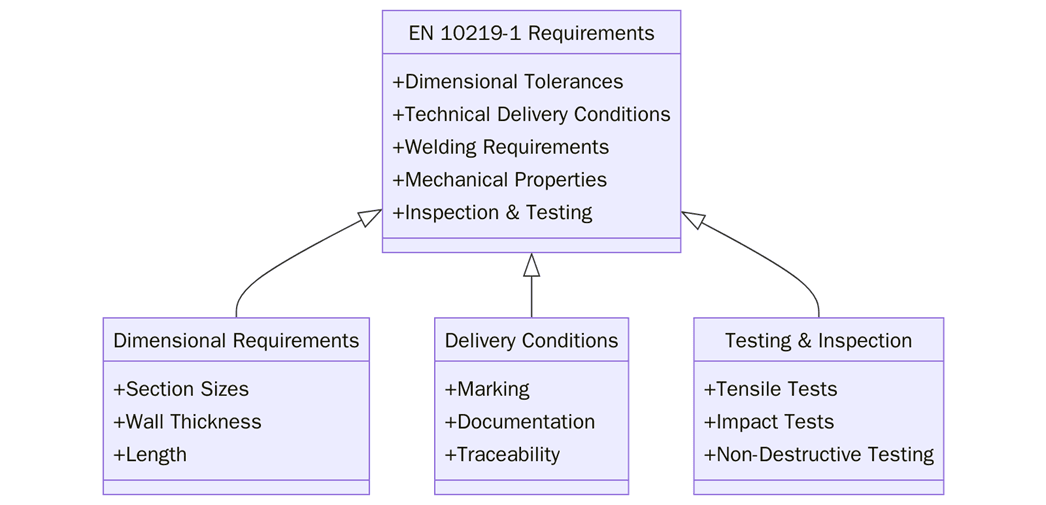

What are the EN 10219-1 requirements?

Before implementing EN 10219-1, organizations must ensure adherence to technical, mechanical, and documentation requirements that guarantee structural reliability. These requirements provide a framework to standardize production and ensure safety. Below are some of the key requirements:

- All hollow sections must be made from non-alloy or fine grain steel conforming to specified chemical and mechanical properties.

- Sections must maintain consistent dimensional tolerances, including wall thickness, width, height, and straightness.

- Welding must be performed using controlled procedures to prevent defects such as cracks, porosity, or incomplete fusion.

- Heat treatment or stress-relief procedures must be applied where necessary to achieve required mechanical properties.

- Mechanical testing, including tensile and impact tests, must show compliance with EN 10219-1 criteria.

- Proper documentation and traceability of each batch must be maintained, including steel grade, production date, and inspection results.

- Sections must be marked with identification codes, manufacturer details and batch numbers for verification and audit purposes.

- Quality control measures, including visual inspection and non-destructive testing, must be implemented during production.

To learn more about ISO standards, contact our team at support@pacificcert.com

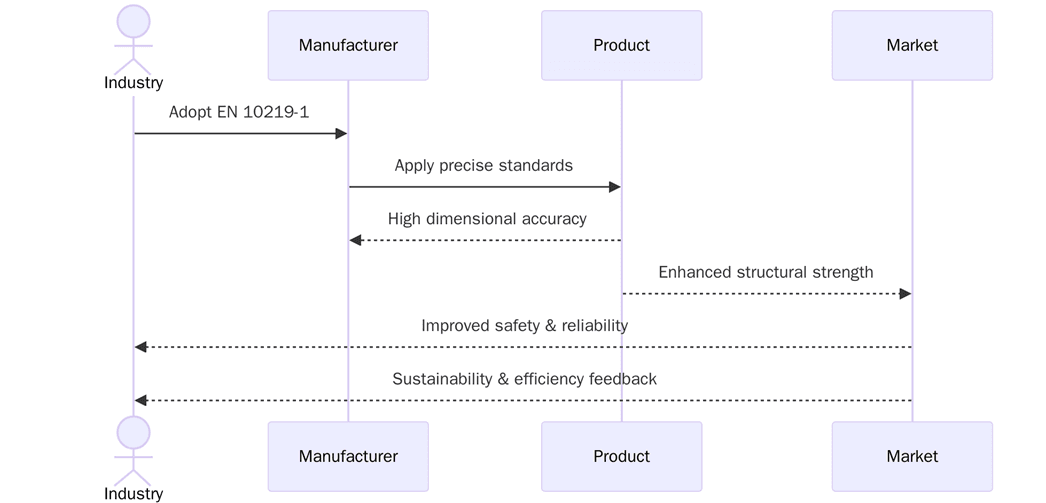

What are the EN 10219-1 benefits?

Adhering to EN 10219-1 offers numerous advantages for manufacturers, engineers and end-users. Below are some of the key benefits:

- Ensures structural reliability by standardizing material and welding properties across all hollow sections.

- Improves safety in construction projects by meeting internationally recognized mechanical and dimensional requirements.

- Improves compatibility with other structural materials and design specifications, reducing engineering errors.

- Supports quality management and traceability, allowing for easier auditing, inspections and regulatory compliance.

- Facilitates international trade and procurement by providing a common standard recognized across countries.

- Reduces risk of failures or rejections during fabrication or construction due to uniform production standards.

- Increases market confidence among clients, contractors, and engineers due to compliance with recognized safety standards.

- Enables smooth project planning and cost estimation by providing predictable material properties and dimensions.

EN 10219-1 Certification Process

The certification process for EN 10219-1 involves multiple stages to verify compliance with all technical and safety requirements:

- Gap Assessment – Review current production, welding, and quality control practices to identify areas that require updates.

- Material Verification – Ensure raw steel meets chemical and mechanical property requirements.

- Production Audit – Evaluate cold-forming, welding and fabrication procedures to confirm compliance with EN 10219-1.

- Testing and Inspection – Conduct mechanical tests, dimensional checks, and weld inspections on sample sections.

- Documentation Review – Assess traceability, marking and certification documents to ensure full compliance.

- Third-Party Verification – Engage accredited certification bodies to validate production and quality systems.

- Corrective Actions – Implement any required improvements identified during the audit and verification steps.

- Certification Issuance – Upon successful verification, receive certification confirming alignment with EN 10219-1.

- Ongoing Compliance – Periodic surveillance audits to ensure continued adherence to the standard and maintain certification.

For more information or to initiate certification, contact Pacific Certifications at support@pacificcert.com.

What is the Certification Timeline for EN 10219-1

The timeline for obtaining EN 10219-1 certification generally ranges from three to six months depending on the complexity of the production process, size of the manufacturing facility, and readiness of existing quality systems. Organizations with established steel production lines and prior experience with EN standards may complete the process in approximately three months, while those implementing new procedures or production modifications may require up to six months. The timeline includes preparation, internal review, testing, third-party verification, corrective actions and certification issuance. Ongoing monitoring ensures compliance is maintained after certification.

What is the Certification Cost for EN 10219-1?

The cost of EN 10219-1 certification varies depending on the size of the production facility, number of hollow section types, extent of testing required, and the need for third-party verification. Costs typically include internal preparation, staff training, testing and inspection, documentation and certification body fees. Larger manufacturers or organizations producing multiple section types may incur higher costs due to the increased complexity of audits and testing. While the investment varies, EN 10219-1 certification ensures material reliability, improves safety, supports regulatory compliance, and improves market acceptance of structural hollow sections.

How Pacific Certifications Can Help?

Pacific Certifications assists organizations in aligning their hollow section manufacturing and quality systems with EN 10219-1 requirements. We provide:

- Gap assessments of existing production and quality processes

- Verification of welding, material properties, and dimensional compliance

- Support in documentation, traceability, and marking requirements

- Assistance during third-party audits and certification processes

- Training for staff on standard requirements and quality control best practices

To schedule a certification audit or discuss EN 10219-1 compliance, contact our team at support@pacificcert.com.

Training and Courses

Pacific Certifications offers accredited training programs to support the adoption and implementation of EN 10219-1 standards:

- Lead Auditor Training– Prepares professionals to conduct third-party audits of hollow section production.

- Lead Implementer Training– Guides personnel responsible for integrating EN 10219-1 requirements into production and quality management systems.

- Internal Auditor Training– Equips internal teams to perform audits and maintain ongoing compliance

Contact support@pacificcert.com for enrolment and course details.

FAQs

What industries use EN 10219-1 certified hollow sections?

EN 10219-1 is widely used in construction, industrial frameworks, bridges, high-rise buildings, and infrastructure projects requiring load-bearing steel sections.

Is EN 10219-1 mandatory for all steel hollow sections?

It is not legally mandatory but is highly recommended for manufacturers and fabricators aiming to meet international quality and safety standards.

How long does it take to get EN 10219-1 certification?

The process typically takes three to six months depending on facility size, production complexity, and readiness of quality systems.

Can EN 10219-1 certified sections be used internationally?

Yes. The standard is recognized internationally, making certified hollow sections suitable for export and cross-border projects.

What types of testing are required for certification?

Mechanical tests, impact tests, dimensional verification, and weld inspections are conducted to confirm compliance with EN 10219-1.

Does certification cover all hollow section shapes?

Yes, the standard applies to round, square, and rectangular sections produced from non-alloy and fine grain steels.

Are documentation and marking important for EN 10219-1?

Yes. Proper traceability, batch documentation, and marking are mandatory for certification and audit purposes.

How often are surveillance audits conducted?

Typically, annual surveillance audits are conducted to ensure ongoing compliance with EN 10219-1.

Can small manufacturers get EN 10219-1 certification?

Yes. Certification is achievable for manufacturers of any size if production processes and quality systems meet the standard.

What benefits does certification provide for clients?

Certification assures structural reliability, safety, traceability, international acceptance and confidence in steel hollow section performance.

Contact Us

If you need support with EN 10219-1 certification, contact us at support@pacificcert.com.

Read More at: Blogs by Pacific Certifications