What is EN 149?

EN 149 is a European standard that specifies the performance testing and marking requirements for filtering half masks designed to protect against particles. These masks are commonly referred to as FFP masks—FFP1 FFP2 and FFP3—based on their filtration capacity. EN 149 is widely used in industries like construction mining chemicals pharmaceuticals and especially healthcare where workers are regularly exposed to airborne hazards. This standard supports product design manufacturing and testing to ensure these masks provide reliable respiratory protection during daily use.

Organizations that manufacture or supply personal protective equipment (PPE) particularly respiratory masks, adopt EN 149 to ensure their products meet safety and performance benchmarks. Hospitals and laboratories depend on certified masks to protect workers from inhaling dust fumes, aerosols and biological agents. EN 149 is critical in occupational health management systems and procurement planning for PPE.

For audits and certification contact support@pacificcert.com

Purpose

The purpose of EN 149 is to provide uniform criteria for the construction performance and evaluation of filtering half masks used as respiratory protective devices. It helps ensure that products offer a consistent barrier against inhalable airborne particles. This allows buyers and users to trust the product’s reliability across work environments that pose respiratory hazards such as dust mist and microorganisms.

Scope and Applicability

EN 149 applies to filtering half masks that are intended to protect the wearer against solid and liquid aerosols. It does not apply to masks designed for escape purposes or to full-face respirators. The standard is especially relevant to sectors such as:

- Healthcare and hospitals

- Pharmaceuticals and labs

- Construction and cement work

- Mining and tunneling

- Food processing

- Welding and metalwork

- Woodworking and carpentry

These masks are used by healthcare workers during disease outbreaks factory employees handling powders or fumes and site workers exposed to dust or smoke. The standard supports both manufacturers and buyers by defining what makes a mask suitable for high-risk tasks.

Key Definitions

Filtering Half Mask:

A mask covering the nose mouth and chin with filter material as the main protective barrier

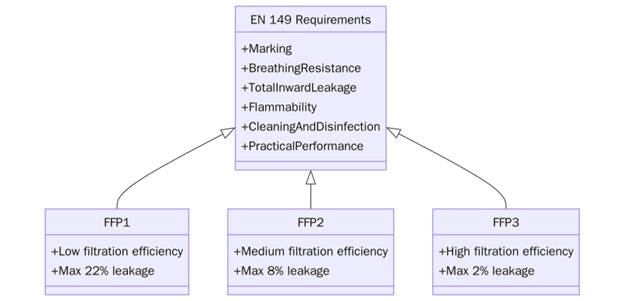

FFP1 FFP2 FFP3:

Filter performance levels. FFP1 filters at least 80 percent FFP2 at least 94 percent and FFP3 at least 99 percent of airborne particles

Total Inward Leakage (TIL):

The percentage of particles that enter the mask compared to the outside environment

Breathing Resistance:

The pressure drop across the mask affecting how easy it is to breathe while wearing it

Dolomite Test:

A clogging test that evaluates the mask’s performance in dusty environments

Structure of EN 149

Clause Number | Title | Description |

1 | Scope | Explains the type of equipment covered and intended use |

2 | Normative References | Lists other relevant standards referred to in EN 149 |

3 | Terms and Definitions | Clarifies key terminology used throughout the standard |

4 | Classification | Defines the FFP classes based on filtering efficiency |

5 | Requirements | Lists general construction design and performance requirements |

6 | Testing | Specifies testing methods for particle filtration breathing resistance etc |

7 | Marking and Packaging | Details requirements for product labeling and packaging |

8 | Information to be Supplied by Manufacturer | Covers the mandatory user instructions and safety info |

What are the requirements of EN 149?

To implement EN 149 organizations must carry out specific design production and evaluation steps to validate filtering masks. These requirements ensure the mask meets safety expectations before it reaches end users. Below are the mandatory requirements:

1. Classify masks as FFP1 FFP2 or FFP3

Classify masks as FFP1 FFP2 or FFP3 based on the filtration level they offer

2. Conduct particle filtration

Conduct particle filtration efficiency testing as per prescribed methods in the standard

3. Perform breathing resistance tests

Perform breathing resistance tests to ensure comfort and usability during extended wear

4. Carry out total inward leakage testing

Carry out total inward leakage testing under various wearing conditions

5. Apply the dolomite clogging test

Apply the dolomite clogging test for specific masks used in dusty environments

6. Include exhalation valve performance checks

Include exhalation valve performance checks if such components are used

7. Clearly mark the masks

Clearly mark the masks with relevant info including FFP class CE mark and manufacturer name

8. Provide user instructions

Provide user instructions covering proper fit usage limits storage and disposal

What are the benefits of EN 149 Certification?

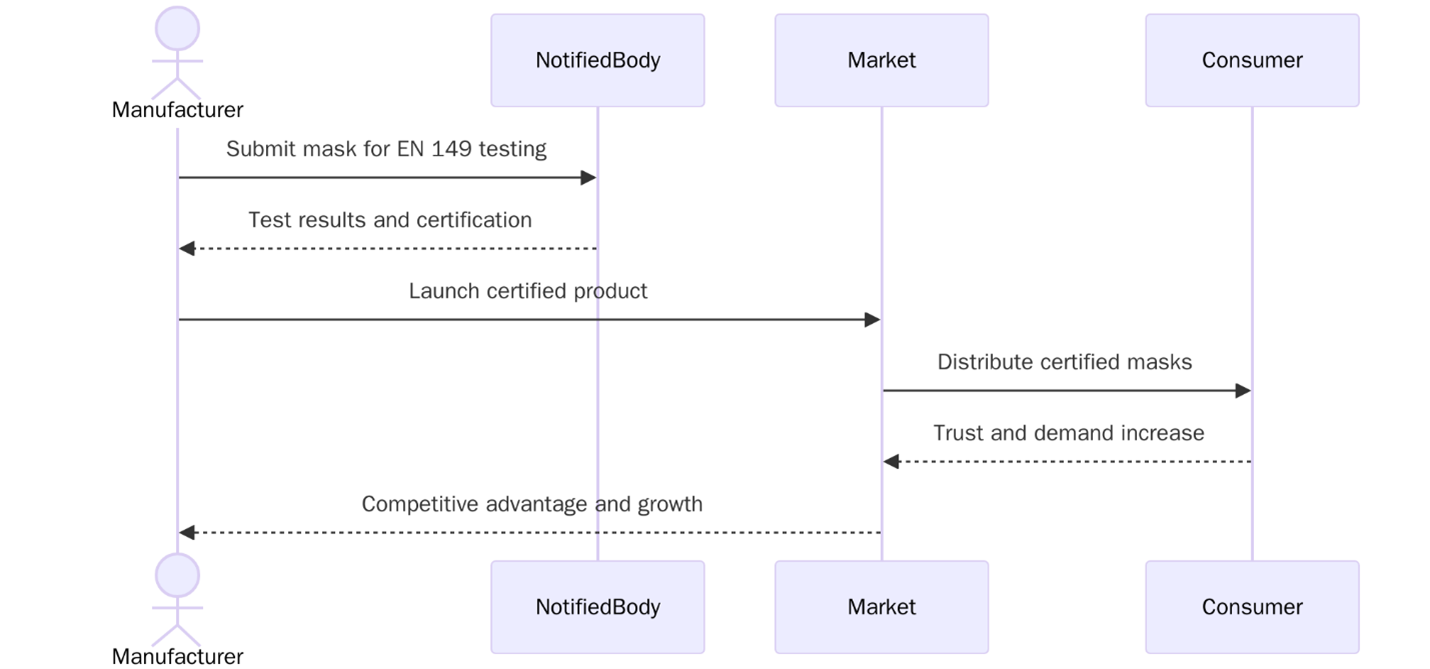

EN 149 certification shows that your product has passed critical safety and filtration tests and is fit for use in workplaces where respiratory protection is required. It adds assurance for buyers, regulators and users. Below are the key benefits:

1. Boosts trust

Boosts trust in mask quality among healthcare and industrial users

2. Helps reduce workplace

Helps reduce workplace exposure to harmful particles

3. Required for public tenders

Required for public tenders and institutional procurement

4. Supports product labeling

Supports product labeling with CE mark for European market

5. Aligns with occupational safety norms

Aligns with occupational safety norms in multiple regions

6. Reduces legal and product liability risks

Reduces legal and product liability risks through documented testing

7. Provides testing benchmarks

Provides testing benchmarks for internal product development

8. Enhances brand image

Enhances brand image among safety-focused buyers

Eligibility Criteria

Manufacturers, importers and distributors of filtering half masks can apply for EN 149 certification. This includes OEMs producing industrial safety gear or medical PPE. Organizations that already have ISO 9001 or API Q1 certified quality systems may find it easier to integrate EN 149 testing and documentation processes. The key is to demonstrate technical capability, traceability in production and access to accredited testing laboratories.

Certification Process: EN 149

1. Initial review

Initial review of product type documentation and intended usage

2. Pre-audit preparation

Pre-audit preparation including selection of mask types labeling setup and readiness for testing

3. Document evaluation

Document evaluation including production records test reports packaging labels and instructions for use

4. Witness testing

Witness testing at accredited labs production walkthroughs interviews with technical staff and random sampling

5. Decision made

Decision made based on audit findings test results and corrective actions if needed

6. Follow-up audits

Follow-up audits to confirm product performance and manufacturing consistency

Timeline for EN 149 Certification

The full process generally takes 8 to 12 weeks. If test reports and labeling details are already prepared the timeline may reduce. For new manufacturers or first-time applicants additional weeks may be required for pre-testing and documentation alignment. Organizations with multiple product variants may undergo testing in phases based on risk level and product volumes.

What is the cost of EN 149?

Costs vary depending on product types the number of variants required for lab tests and the need for follow-up testing. Additional cost factors include availability of documentation, manufacturer readiness and scope of certification. Companies with existing QMS frameworks and tested product lines may reduce overall effort and cost.

How can Pacific Certifications Help?

Pacific Certifications audits companies to EN 149 and evaluates their production processes documentation and product test performance for filtering half masks. Our team works closely with technical staff lab partners and quality managers to ensure every aspect of the certification is completed with precision. We support both standalone EN 149 audits and integrated certifications such as ISO 9001. As an ABIS -accredited certification body Pacific Certifications is trusted for its industry knowledge and experience in PPE compliance.

Key support we offer:

- Product and document review for all FFP mask classes

- Coordination with accredited labs for mandatory testing

- Guidance on labeling packaging and CE marking

- Combined audits with ISO 9001 for efficiency

- Ongoing support during annual surveillance audits

EN 149 Training and Courses

Lead Auditor Training

Teaches professionals how to audit manufacturing and quality systems against EN 149

Lead Implementer Training

Guides internal teams on how to set up systems to comply with EN 149 across product lines

Internal Auditor Training

Designed for in-house quality staff to monitor and assess compliance throughout the production process

Pacific Certifications provides accredited training programs. Contact support@pacificcert.com to schedule your training or to start your certification process!

FAQs

Can we certify multiple FFP classes under one audit?

Yes. FFP1 FFP2 and FFP3 masks can be grouped if design and production controls are similar

How long does an EN 149 audit take?

Audits and testing typically take 2 to 3 months depending on readiness and number of product types

Is EN 149 certification mandatory for selling in the EU?

Yes. Masks intended for occupational safety must comply with EN 149 and carry the CE mark

Does EN 149 work with ISO 9001 systems?

Yes. A quality management system like ISO 9001 can support the documentation and process needs of EN 149

Do we need third-party lab testing?

Yes. Testing must be done at accredited labs as per EN 149 specifications

What types of companies apply for EN 149?

Mask manufacturers OEMs and PPE suppliers targeting healthcare construction and industrial sectors

Ready to get EN 149 certified?

Contact Pacific Certifications to begin your certification journey today!

Suggested Certifications –

Read more: Pacific Blogs