ISO Certifications for Overhead Crane Manufacturing Businesses, Requirements and Benefits

The overhead crane manufacturing industry plays a crucial role in heavy lifting and material handling across multiple sectors, including construction, automotive, steel production & logistics. Ensuring the highest levels of safety and quality in crane manufacturing is essential.

ISO standards provide globally recognized frameworks that help manufacturers to comply with strict quality, safety and environmental requirements. For overhead crane manufacturers, obtaining ISO certification demonstrates commitment to industry best practices and customer satisfaction.

With increasing global demand for automated and high-capacity cranes, implementing ISO standards is more critical than ever. These certifications not only ensure reliability and durability but also enhance business reputation and boost customer trust.

Speak with our certification specialists at +91-8595603096 or email support@pacificcert.com to start your certification process.

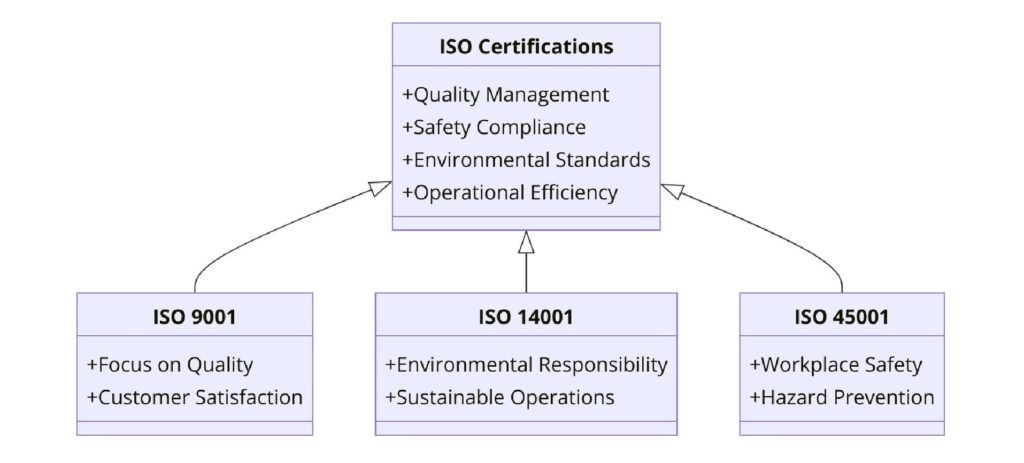

Applicable ISO Standards for Crane Manufacturing

Overhead crane manufacturers must comply with various ISO standards covering quality management, safety, environmental impact, and operational efficiency. Here are the key ISO certifications applicable to the industry:

ISO 9001:2015 – Quality Management System (QMS): ISO 9001:2015 is a globally recognized standard that ensures manufacturers follow a structured approach to quality management. It emphasizes customer satisfaction, process efficiency, and continual improvement.

Key Focus Areas:

- Quality control throughout the manufacturing process

- Risk management and mitigation

- Enhanced customer satisfaction through consistent product quality

- Data-driven decision-making for process improvements

ISO 14001:2015 – Environmental Management System (EMS): Overhead crane manufacturing involves metal fabrication, welding, and coating processes that impact the environment. ISO 14001:2015 helps manufacturers minimize their environmental footprint through responsible resource use and waste management.

Key Focus Areas:

- Pollution prevention and waste reduction

- Compliance with environmental regulations

- Sustainable material sourcing and energy efficiency

- Reducing emissions during manufacturing

ISO 45001:2018 – Occupational Health and Safety Management System (OHSMS): Worker safety is paramount in crane manufacturing due to the high-risk nature of the job. ISO 45001:2018 helps manufacturers establish a safe working environment, reducing accidents, injuries, and health risks.

Key Focus Areas:

- Identifying and controlling workplace hazards

- Ensuring compliance with safety regulations

- Employee training and safety awareness

- Reducing workplace incidents and associated costs

ISO 3834 – Quality Requirements for Fusion Welding: Since welding is a core process in overhead crane production, ISO 3834 ensures that manufacturers meet high welding quality standards. Compliance with this standard guarantees structural integrity, durability, and safety.

Key Focus Areas:

- Proper welding procedures and techniques

- Inspection and testing of welded joints

- Qualification of welding personnel

- Documentation of welding processes

ISO 9927 – Crane Inspection and Maintenance: ISO 9927 provides inspection, maintenance, and monitoring guidelines to ensure the safe operation of overhead cranes. Manufacturers who comply with this standard can enhance crane longevity and reduce risks of mechanical failure.

Key Focus Areas:

- Regular crane inspections

- Preventive maintenance programs

- Compliance with safety regulations

- Reducing downtime and repair costs

Click here to find out more applicable standards to your industry

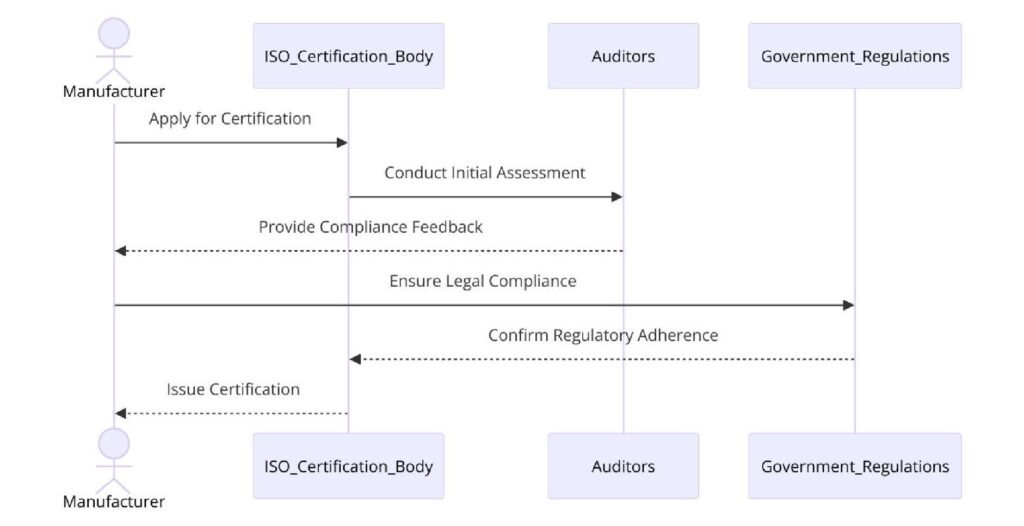

At Pacific Certifications, we specialize in auditing and certifying overhead crane manufacturers against relevant ISO standards. With years of experience in the certification industry, we help businesses to demonstrate compliance and enhance credibility in the market.

As a certification body, we conduct thorough audits and assessments to ensure that your manufacturing processes align with ISO requirements. Once compliance is verified, we issue ISO certifications that validate your commitment to quality, safety & environmental responsibility.

To get certified, reach out to Pacific Certifications today!

Contact us via support@pacificcert.com or call +91-8595603096 to book a discussion on your certification needs.

Requirements of ISO Certifications for Overhead Crane Manufacturing

Each ISO standard has specific requirements that crane manufacturers must meet to achieve certification. Below is a breakdown of the key requirements for each relevant ISO standard:

ISO 9001:2015 – Quality Management System (QMS)

- ✔ Establish a documented quality management system (QMS)

- ✔ Define quality objectives and customer satisfaction metrics

- ✔ Implement risk management and continuous improvement processes

- ✔ Maintain detailed records of manufacturing and inspections

- ✔ Conduct regular internal audits and management reviews

ISO 14001:2015 – Environmental Management System (EMS)

- ✔ Identify and control environmental impacts of manufacturing processes

- ✔ Develop a waste management and pollution control plan

- ✔ Ensure compliance with environmental laws and regulations

- ✔ Improve energy efficiency and sustainable material usage

- ✔ Implement emergency preparedness for environmental hazards

ISO 45001:2018 – Occupational Health and Safety Management System (OHSMS)

- ✔ Conduct hazard identification and risk assessment for workplace safety

- ✔ Implement safety procedures to prevent accidents and injuries

- ✔ Provide employee training on health and safety protocols

- ✔ Ensure emergency response planning and incident reporting

- ✔ Regularly monitor workplace safety performance

ISO 3834 – Quality Requirements for Fusion Welding

- ✔ Use qualified welding personnel and certified procedures

- ✔ Conduct material and weld inspections to ensure integrity

- ✔ Maintain detailed records of welding processes and testing

- ✔ Ensure adequate storage and handling of welding consumables

- ✔ Implement non-destructive testing (NDT) for welded joints

ISO 9927 – Crane Inspection and Maintenance

- ✔ Establish routine inspection and maintenance schedules

- ✔ Document all crane inspections, repairs, and servicing activities

- ✔ Ensure compliance with load capacity and safety regulations

- ✔ Train personnel on proper crane operation and maintenance

- ✔ Implement corrective actions for identified defects

By meeting these ISO requirements, overhead crane manufacturers can ensure product quality, safety and regulatory compliance. If you’re ready to achieve ISO certification, contact us at Pacific Certifications today at support@pacificcert.com.

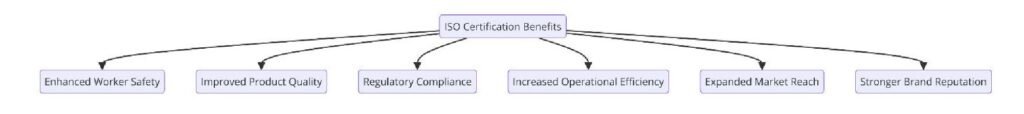

Benefits of ISO Certifications for Overhead Crane Manufacturing

Obtaining ISO certification offers numerous benefits for manufacturers, employees, and customers:

Product Quality: ISO 9001 certification ensures that overhead cranes are manufactured with precision, consistency, and durability, leading to improved product reliability.

Safety & Compliance: ISO 45001 and ISO 9927 help manufacturers reduce workplace accidents and ensure compliance with international safety standards.

Environmental Responsibility: ISO 14001 certification enables manufacturers to reduce emissions, waste, and resource consumption, enhancing corporate social responsibility (CSR).

Competitive Advantage: ISO-certified manufacturers have a higher chance of securing government contracts, international projects, and partnerships with major industries.

Efficiency & Cost Savings: Standardized processes lead to reduced defects, less rework, and lower operational costs, ultimately increasing profitability.

This year, the global crane market is witnessing significant growth due to rising demand in construction, shipbuilding, and warehousing. Reports indicate that automation, AI-powered maintenance systems, and IoT-enabled smart cranes are becoming industry standards.

Key Market Trends:

- Growth in automated and remotely operated cranes

- Expansion of the green manufacturing movement with eco-friendly production techniques

- Adoption of predictive maintenance using AI and data analytics

These trends highlight the increasing importance of ISO certifications, as businesses must meet higher safety, efficiency and sustainability benchmarks.

Are you an overhead crane manufacturer looking to enhance product quality, safety, and compliance? At Pacific Certifications, we provide reliable auditing and certification services to help you meet ISO requirements effortlessly.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Overhead Crane Manufacturing business, please contact us at suppport@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Overhead Crane Manufacturing

ISO certification ensures that manufacturers comply with quality, safety, and environmental standards, improving reliability and market credibility.

The certification timeline depends on company size, existing processes, and readiness but typically ranges from a few weeks to several months.

No, Pacific Certifications specializes only in auditing and certification issuance.

While not legally mandatory, ISO certification is often required for government contracts, large-scale projects, and international business partnerships.

Simply email us at support@pacificcert.com to discuss your certification requirements.

Read More at: Blogs by Pacific Certifications