ISO Certifications for Toy and Sporting Goods Manufacturing Businesses, Requirements and Benefits

Ensuring safety and compliance is paramount in the toy and sporting goods industry. In an era of heightened consumer awareness and stringent global regulations, ISO certifications provide a standardized approach to manufacturing excellence. By implementing internationally recognized standards, manufacturers can enhance product reliability, meet customer expectations, and compete effectively in global markets.

ISO standards are globally recognized frameworks designed to improve efficiency, safety, and quality across various industries. For toy and sporting goods manufacturers, these standards address critical aspects such as product safety, environmental responsibility, and management system optimization.

In the toy industry, the focus on child safety is paramount, given the vulnerabilities of the target audience. Sporting goods, used in diverse environments, demand robustness and precision. ISO certifications ensure that these critical factors are adhered to, fostering trust among consumers and regulatory bodies.

Pacific Certifications specializes in helping manufacturers achieve compliance through certification and audit services, ensuring seamless alignment with ISO requirements.

Contact us at support@pacificcert.com for personalized guidance on your certification needs.

Applicable ISO Standards for Toy and Sporting Goods Manufacturing

Several ISO standards apply to toy and sporting goods manufacturing, each addressing specific areas of quality, safety, and management:

ISO 8124: Safety of Toys: ISO 8124 specifies safety requirements for toys, addressing mechanical, physical, and chemical hazards. It ensures that toys are safe for children during normal use or foreseeable misuse.

ISO 9001: Quality Management System: ISO 9001 focuses on improving product quality and operational efficiency. It ensures consistent production processes and customer satisfaction.

ISO 14001: Environmental Management System: ISO 14001 promotes sustainable practices, helping manufacturers reduce their environmental impact through effective resource management and compliance with environmental regulations.

ISO 45001: Occupational Health and Safety Management: This standard emphasizes workplace safety, minimizing risks and improving the health and well-being of employees involved in toy and sporting goods production.

ISO 50001: Energy Management: ISO 50001 assists manufacturers in optimizing energy use, reducing costs, and enhancing sustainability.

ISO 17025: Testing and Calibration Laboratories: ISO 17025 ensures that testing and calibration labs associated with manufacturing meet high standards of accuracy and reliability.

ISO 26000: Social Responsibility: This standard offers guidance on ethical business practices, focusing on social responsibility and fair labor practices in the manufacturing sector.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we offer professional audit and certification services to help your organization align with applicable ISO standards. Our team ensures thorough assessments to validate compliance, providing certifications that enhance your brand’s credibility and market access.

We understand the complexities of ISO certification processes and offer support to streamline your journey toward achieving globally recognized standards. By partnering with Pacific Certifications, manufacturers can demonstrate their commitment to quality, safety, and sustainability.

Drop us an email to book a dedicated session with our certification specialists.

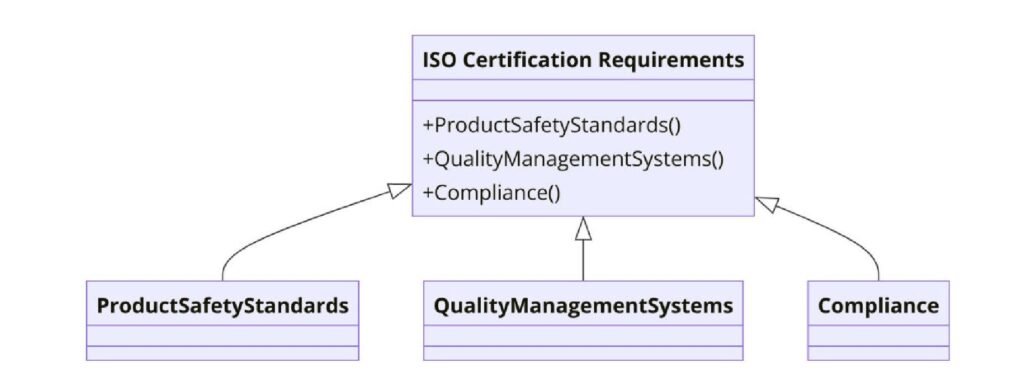

Requirements of ISO Certifications for Toy and Sporting Goods Manufacturing

To achieve ISO certifications in the toy and sporting goods manufacturing industry, companies must meet specific requirements outlined in each standard. These requirements are tailored to address critical areas like product safety, quality management, environmental responsibility, and workplace safety. Here’s a breakdown of the key requirements for each applicable standard:

ISO 8124: Safety of Toys

This standard focuses exclusively on the safety of toys, with detailed requirements to ensure children’s well-being.

- Physical and Mechanical Properties: Toys must withstand normal use and foreseeable misuse without posing hazards like choking, sharp edges, or pinching.

- Flammability Testing: Materials used in toys must comply with strict flammability regulations to prevent fire-related risks.

- Chemical Safety: Testing for toxic substances like lead, phthalates, and other harmful chemicals is mandatory to ensure child safety.

- Labeling and Instructions: Clear warnings and age-appropriate labeling must be provided to guide proper usage and avoid risks.

ISO 9001: Quality Management System (QMS)

ISO 9001 establishes a framework for improving quality and consistency in manufacturing.

- Quality Policy: Manufacturers must define a quality policy aligned with their strategic goals and customer needs.

- Documented Processes: Standardized operating procedures (SOPs) for all production activities must be implemented.

- Risk Management: Organizations need to identify risks and opportunities, implementing controls to mitigate adverse impacts.

- Customer Focus: Continuous improvement processes must prioritize customer satisfaction.

ISO 14001: Environmental Management System (EMS)

ISO 14001 helps manufacturers minimize their environmental footprint.

- Environmental Policy: Establishing a policy that reflects a commitment to sustainability is required.

- Compliance Obligations: Manufacturers must identify and comply with environmental regulations relevant to their operations.

- Resource Management: Efficient use of energy, water, and raw materials is essential to reduce waste and pollution.

- Monitoring and Reporting: Regular audits and environmental performance assessments must be conducted.

ISO 45001: Occupational Health and Safety Management

This standard ensures safe working conditions for employees in manufacturing facilities.

- Hazard Identification: Organizations must identify workplace hazards and implement risk controls.

- Employee Training: Regular training programs on safety protocols and emergency responses are required.

- Incident Reporting: Systems for reporting and investigating workplace accidents must be in place.

- Continuous Improvement: Manufacturers should actively seek opportunities to enhance workplace safety measures.

ISO 50001: Energy Management System (EnMS)

ISO 50001 focuses on optimizing energy usage to enhance efficiency and reduce costs.

- Energy Review: Organizations must analyze current energy consumption patterns and identify areas for improvement.

- Energy Performance Indicators (EnPIs): Specific metrics must be established to track energy efficiency progress.

- Energy Management Plan: A comprehensive plan to implement energy-saving technologies and practices is necessary.

- Monitoring and Verification: Regular checks to ensure adherence to energy objectives are essential.

ISO 17025: Testing and Calibration Laboratories

For manufacturers with in-house testing facilities, ISO 17025 ensures laboratory accuracy and reliability.

- Competency Requirements: Personnel conducting tests must be qualified and trained.

- Equipment Calibration: Testing equipment must be regularly calibrated to maintain precision.

- Documentation: Detailed records of testing procedures, results, and analysis must be maintained.

- Method Validation: Testing methods must be validated for accuracy and reliability.

ISO 26000: Social Responsibility

ISO 26000 encourages ethical practices in the manufacturing sector.

- Fair Labor Practices: Ensuring fair wages, safe working conditions, and equal opportunities for all employees.

- Community Engagement: Actively contributing to community development and local social initiatives.

- Transparent Operations: Communicating openly about business practices and their societal impacts.

Meeting these requirements is essential for achieving and maintaining ISO certifications, demonstrating a manufacturer’s commitment to safety, quality, and ethical practices. By adhering to these standards, toy and sporting goods manufacturers can enhance their market reputation and gain consumer trust.

Send your queries to support@pacificcert.com at any time, and we’ll respond promptly.

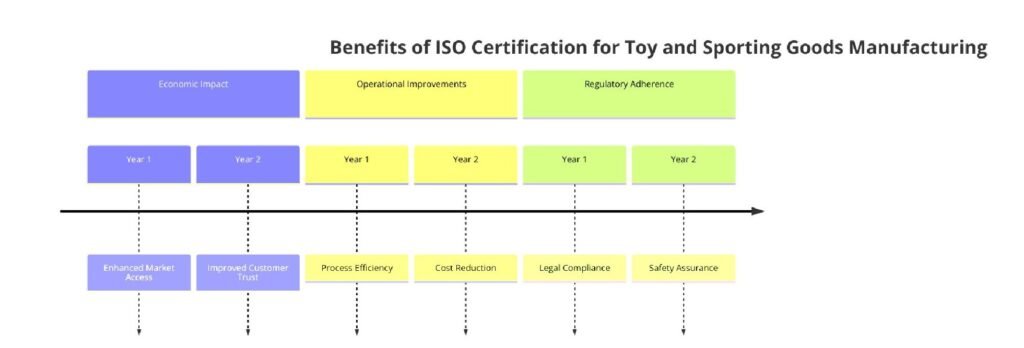

Benefits of ISO Certifications for Toy and Sporting Goods Manufacturing

Implementing ISO standards provides a range of advantages for manufacturers in the toy and sporting goods sector:

Enhanced Product Safety: ISO standards help mitigate risks associated with toys and sporting goods, ensuring products are safe for consumers.

Global Market Access: ISO certifications are recognized worldwide, enabling manufacturers to expand into international markets while meeting regional regulations.

Customer Trust and Satisfaction: Compliance with ISO standards demonstrates a commitment to quality and safety, fostering consumer confidence.

Operational Efficiency: Streamlined processes under ISO 9001 improve productivity, reduce waste, and lower operational costs.

Sustainability and Environmental Stewardship: Adhering to ISO 14001 and ISO 50001 underscores a commitment to eco-friendly practices, appealing to environmentally conscious consumers.

Regulatory Compliance: ISO standards ensure alignment with national and international regulations, reducing the risk of legal complications.

Improved Workforce Morale: ISO 45001 promotes a safe work environment, boosting employee morale and productivity.

Call +91-8595603096 to discuss how we can help you achieve ISO certification for your toy and sporting goods manufacturing business.

The global toy and sporting goods market is projected to grow significantly in 2024, driven by rising consumer demand for sustainable and innovative products. According to industry research, manufacturers focusing on eco-friendly materials and smart technologies are gaining a competitive edge.

ISO certifications play a pivotal role in addressing these trends, ensuring that products meet both consumer expectations and regulatory standards. By staying compliant with ISO frameworks, manufacturers can position themselves as leaders in a rapidly evolving market.

Achieving ISO certifications is a transformative step for your toy and sporting goods manufacturing business. Whether you aim to enhance product safety, improve operational efficiency, or expand into international markets, compliance with ISO standards is essential.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Toy and Sporting Goods Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Toy and Sporting Goods Manufacturing

ISO certifications ensure the safety and quality of toys, helping manufacturers comply with global standards and consumer safety requirements.

ISO 8124 is the primary standard for toy safety, covering mechanical, physical, and chemical hazards.

ISO 9001 improves product quality and operational efficiency, ensuring consistent production processes and customer satisfaction.

While not mandatory, ISO certifications are often required by regulatory bodies and consumers in many international markets.

ISO 14001 focuses on environmental management, helping manufacturers reduce their environmental impact and promote sustainability.

Pacific Certifications provides audit and certification services, ensuring that manufacturers meet applicable ISO standards and gain global recognition.

Read More at: Blogs by Pacific Certifications