ISO Certifications for Paint and Coatings Manufacturing, Requirements and Benefits

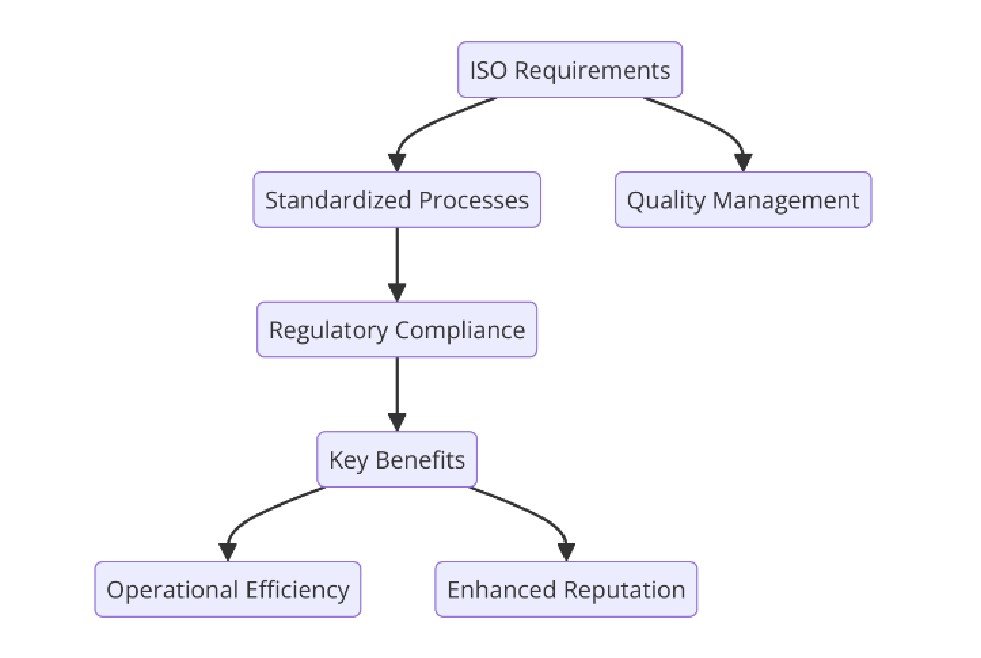

Manufacturers in the paint and coatings industry operate in a highly regulated and competitive market where quality and safety are paramount. In this context, ISO certifications serve as a vital tool to ensure compliance and enhance credibility. This article delves into the key ISO standards applicable to paint and coatings manufacturing, their requirements, and the benefits they bring to this dynamic industry.

ISO standards are globally recognized benchmarks designed to optimize processes, improve product quality, and uphold safety. In the paint and coatings sector, these standards are particularly critical because the industry deals with chemical formulations that must meet rigorous health, safety, and environmental guidelines.

For manufacturers, achieving ISO certification signifies adherence to best practices, paving the way for regulatory compliance and customer trust. From environmental management to occupational health and safety, these standards encompass a wide range of factors that shape the production and distribution of high-quality paints and coatings.

Contact us for ISO certification tailored to the paint and coatings industry. Email: support@pacificcert.com. Phone: +91-8595603096.

Applicable ISO Standards for Paint and Coatings Manufacturing

Various ISO standards cater to the specific needs of paint and coatings manufacturing. Below is an overview of the most relevant ones:

ISO 9001: Quality Management Systems: This standard provides a framework for consistent product quality and customer satisfaction. It is critical for optimizing manufacturing processes, reducing waste, and ensuring repeatability in production.

ISO 14001: Environmental Management Systems: With sustainability being a growing concern, ISO 14001 helps manufacturers manage their environmental impact. From waste management to resource efficiency, it ensures compliance with environmental regulations.

ISO 45001: Occupational Health and Safety Management Systems: Paint and coatings manufacturing often involves hazardous substances. ISO 45001 addresses workplace safety, helping manufacturers reduce risks and ensure a safe environment for employees.

ISO 28000: Supply Chain Security Management: This standard supports manufacturers in securing their supply chains, mitigating risks such as counterfeit raw materials and ensuring timely delivery of inputs.

ISO 50001: Energy Management Systems: Energy efficiency is vital in reducing production costs and carbon footprints. ISO 50001 enables organizations to adopt systematic energy management practices.

ISO 12944: Corrosion Protection of Steel Structures: For paints designed to prevent corrosion, adherence to ISO 12944 ensures that products meet rigorous performance standards.

ISO 21401: Sustainability in Tourism (Applicable for hospitality coatings): This niche standard may apply to coatings used in eco-friendly resorts and tourism-focused infrastructure, aligning them with sustainability goals.

Click here to find out more applicable standards to your industry

At Pacific Certifications, we specialize in providing comprehensive ISO certification services tailored to the paint and coatings industry. Our experienced auditors guide organizations through the certification process, ensuring that they meet the stringent requirements of ISO standards.

While we do not provide consultancy or training, our expertise lies in thorough audits and unbiased assessments. Whether you need certification for quality, safety, or environmental management, Pacific Certifications ensures a seamless certification experience.

Get in touch with us for seamless audits and certification. Email us at support@pacificcert.com or dial +91-8595603096.

Requirements of ISO Certifications for Paint and Coatings Manufacturing

Each ISO standard comes with a unique set of requirements that manufacturers must meet. Here’s an outline of the key requisites:

ISO 9001: Quality Management Systems

- Implementation of a quality policy and objectives.

- Defined roles and responsibilities across the organization.

- Continuous monitoring and improvement of production processes.

- Customer feedback mechanisms to enhance satisfaction.

ISO 14001: Environmental Management Systems

- Identification of environmental aspects and impacts.

- Development of objectives to reduce the carbon footprint.

- Compliance with legal and regulatory environmental requirements.

- Emergency preparedness for environmental incidents.

ISO 45001: Occupational Health and Safety

- Risk assessment for workplace hazards.

- Implementation of health and safety policies.

- Training programs for employees on safety practices.

- Regular audits and reviews to improve workplace safety.

ISO 50001: Energy Management

- Monitoring and measurement of energy consumption.

- Identification of opportunities for energy efficiency.

- Integration of energy management into organizational strategy.

ISO 12944: Corrosion Protection

- Evaluation of environmental conditions for coatings.

- Testing protocols to ensure product durability.

- Documentation and traceability of materials used in manufacturing.

Contact Pacific Certifications for professional assistance in paint and coatings manufacturing. Write to support@pacificcert.com or call us at +91-8595603096.

Benefits of ISO Certifications for Paint and Coatings Manufacturing

Achieving ISO certification is more than a regulatory requirement—it’s a strategic advantage that delivers measurable benefits.

Product Quality: ISO 9001 ensures consistency and reliability in manufacturing processes, resulting in superior product quality.

Regulatory Compliance: Standards like ISO 14001 and ISO 45001 help manufacturers stay compliant with stringent environmental and safety regulations.

Market Competitiveness: Certification boosts market credibility, enabling manufacturers to attract environmentally conscious clients and tap into global markets.

Risk Mitigation: By addressing workplace hazards and supply chain vulnerabilities, ISO standards reduce the likelihood of costly disruptions.

Efficiency: Energy management under ISO 50001 can significantly lower energy costs, while quality management reduces waste and enhances productivity.

Customer Trust: ISO certifications act as a seal of trust, assuring customers of the quality and sustainability of products.

The paint and coatings industry is undergoing a transformative phase in 2024, with a focus on eco-friendly formulations and digital technologies. According to market research, demand for water-based coatings is expected to grow significantly, driven by stricter environmental regulations and consumer preferences for low-VOC (Volatile Organic Compounds) products.

Additionally, manufacturers are leveraging Industry 4.0 technologies, such as IoT and AI, to enhance production efficiency and quality control. ISO standards play a pivotal role in this evolution, aligning traditional practices with modern requirements.

If you’re ready to elevate your paint and coatings manufacturing processes, Pacific Certifications is here to assist with ISO certification. Let us help you achieve compliance, enhance quality, and unlock new market opportunities.

Pacific Certifications is accredited by ABIS, in case you need support with ISO certification for your Paint and Coatings Manufacturing business, please contact us at support@pacificcert.com or +91-8595603096.

FAQs: ISO Certifications for Paint and Coatings Manufacturing

ISO certifications ensure that manufacturers adhere to global best practices in quality, safety, and environmental management, enhancing credibility and operational efficiency.

ISO 9001 focuses on quality management, helping manufacturers deliver consistent, high-quality products and improve customer satisfaction.

While not always mandatory, many industry standards and client requirements make ISO certifications essential for competitive success.

Yes, Pacific Certifications specializes in conducting audits and issuing ISO certifications, ensuring compliance with relevant standards.

ISO 14001 helps manufacturers minimize their environmental impact by optimizing waste management, reducing emissions, and improving resource efficiency.

The use of hazardous chemicals makes workplace safety critical. ISO 45001 provides a framework to identify risks, implement safety protocols, and ensure employee well-being.

Read More at: Blogs by Pacific Certifications